4

2. Insert short yellow hose into the “plastic bottle with two openings” which is supplied. Carefully attach the short

yellow hose to the oil drain fitting on the recovery machine. As hose is tightened on fitting, oil will flow into container.

(Hose is equipped with a depressor which will open core valve in oil drain fitting).

3. When oil has drained completely, disconnect the hose from the system. Unscrew the cap/hose from the bottle and

dispose of the oil into an environmentally approved container.

MAINTENANCE REQUIREMENTS

1. Replace filter if sight glass indicator is red/orange in color. The color change may be green/blue for dry condition when

refrigerant is passing through and red/orange in color for wet condition.

2. Replace filter after recovering refrigerant from a known contaminated system.

3. Replace filter if excessive pressure drop is indicated. Difference of pressure gauge reading before and after filter.

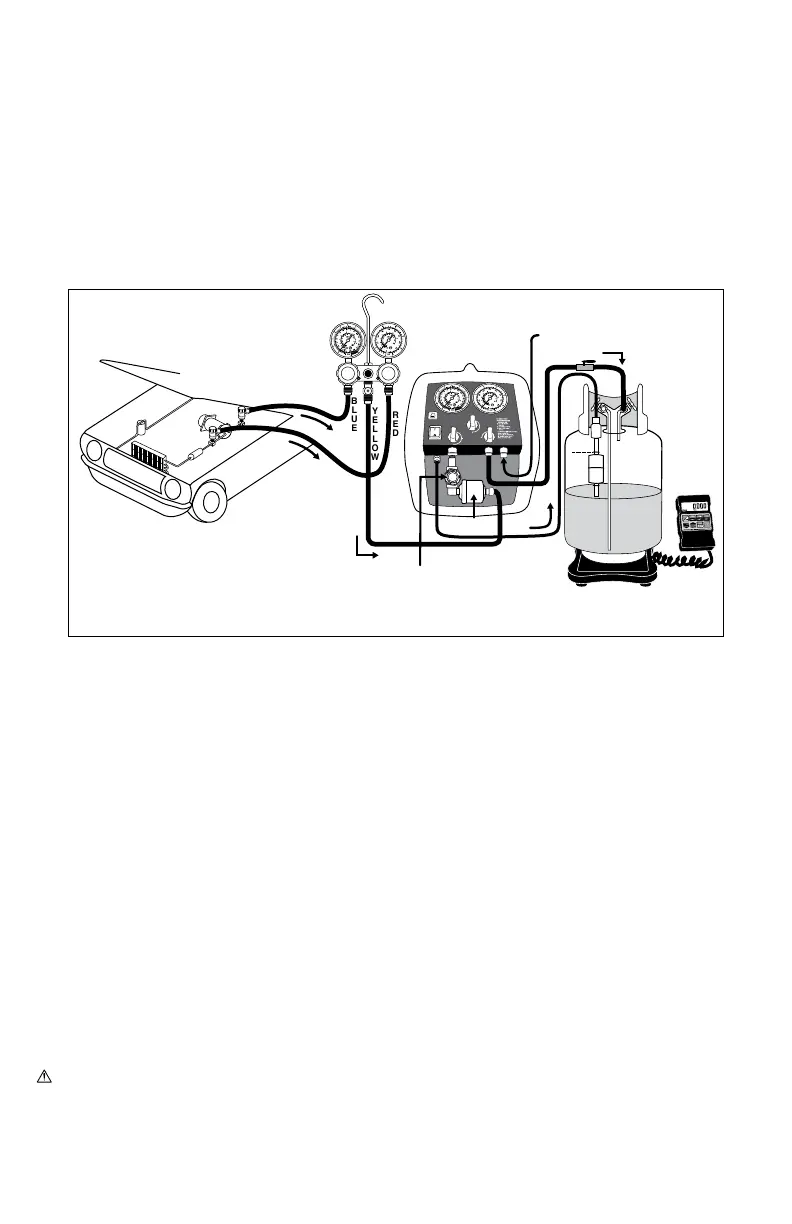

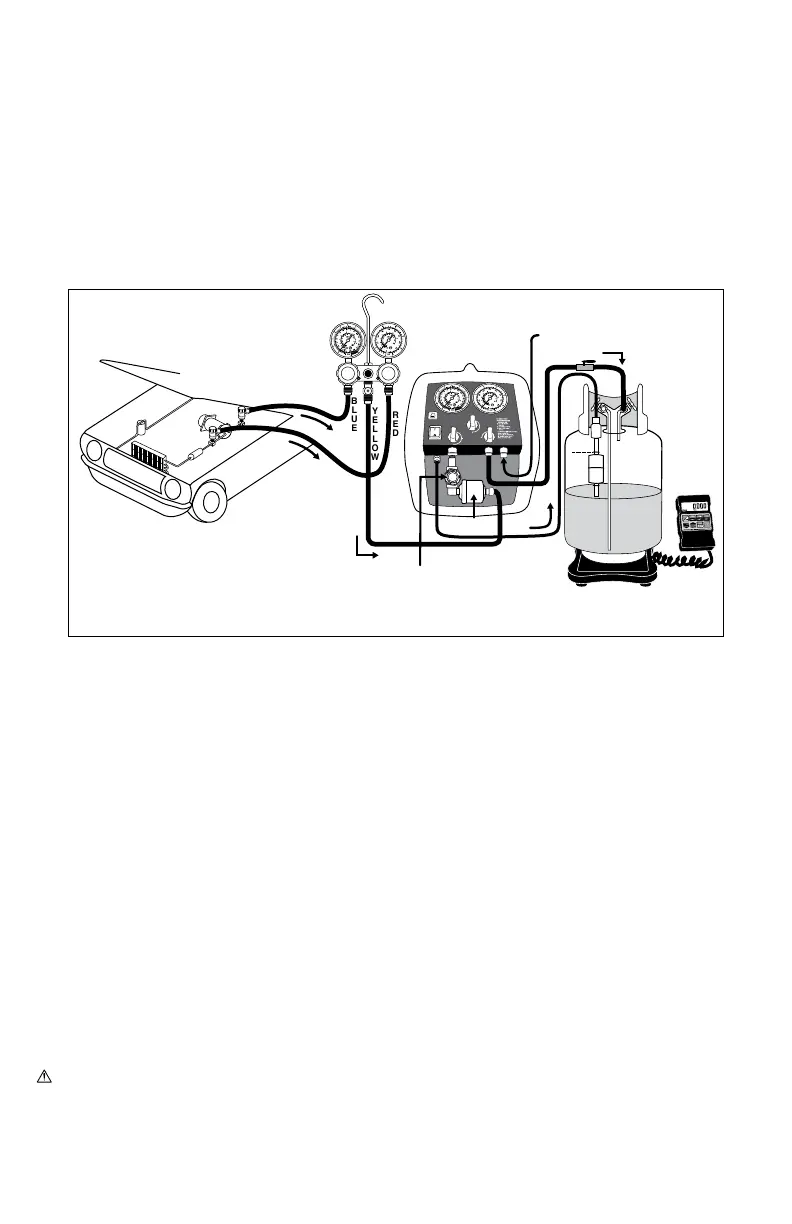

LIQUID

SUCTION PRESSURE DISCHARGE PRESSURE

PURGE

PURGE (START)

INLET

POWER

CIRCUIT

BREAKER

OUTLET

CLOSE

Recovery

System

DO NOT fill tank more

then 80% of capacity!

Approved

Recovery

Tank

Figure 2

Float Switch

Cable

BLUE

YELLOW

RED

Oil Drain Port

80%

YELLOW

Low Side

High Side

Inlet Filter

Sightglass

Moisture

Indicator

To connect yellow hose from

manifold to the recovery, use

provided adapter.

Connections for liquid/vapor recovery using manifold gauge set

69100-INST-UNIV

For parts or service contact the service department: 1-888-825-6989

WARNING: This product can expose you to chemicals including lead and lead compounds, which are known to the

State of California to cause cancer and birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov

Loading...

Loading...