14 www.mastercool.com

1. Connect the couplers to the flush fittings on the side of the machine.

2. Open the couplers by turning the knobs completely clockwise.

3. Open the red and blue valves on the front of the machine. Press next to continue.

4. The machine will now run a hose flushing cycle. This could take several minutes

to ensure the removal of non-compatible oil. Press done to return to main screen.

o IDENTIFICATION: The identification process ensures that R1234yf refrigerant is in the system.

Follow the instructions on the screen. This process will also be performed each time the

machine begins the tank filing or recovery procedure

o UPDATE: This is used for software updates via a USB connection

• DOCUMENTS: The set up video, operational video and owners manual can be displayed on the

machine from the documents section

o MANUALS: to display the owner’s manual.

o TOOLS: to display videos

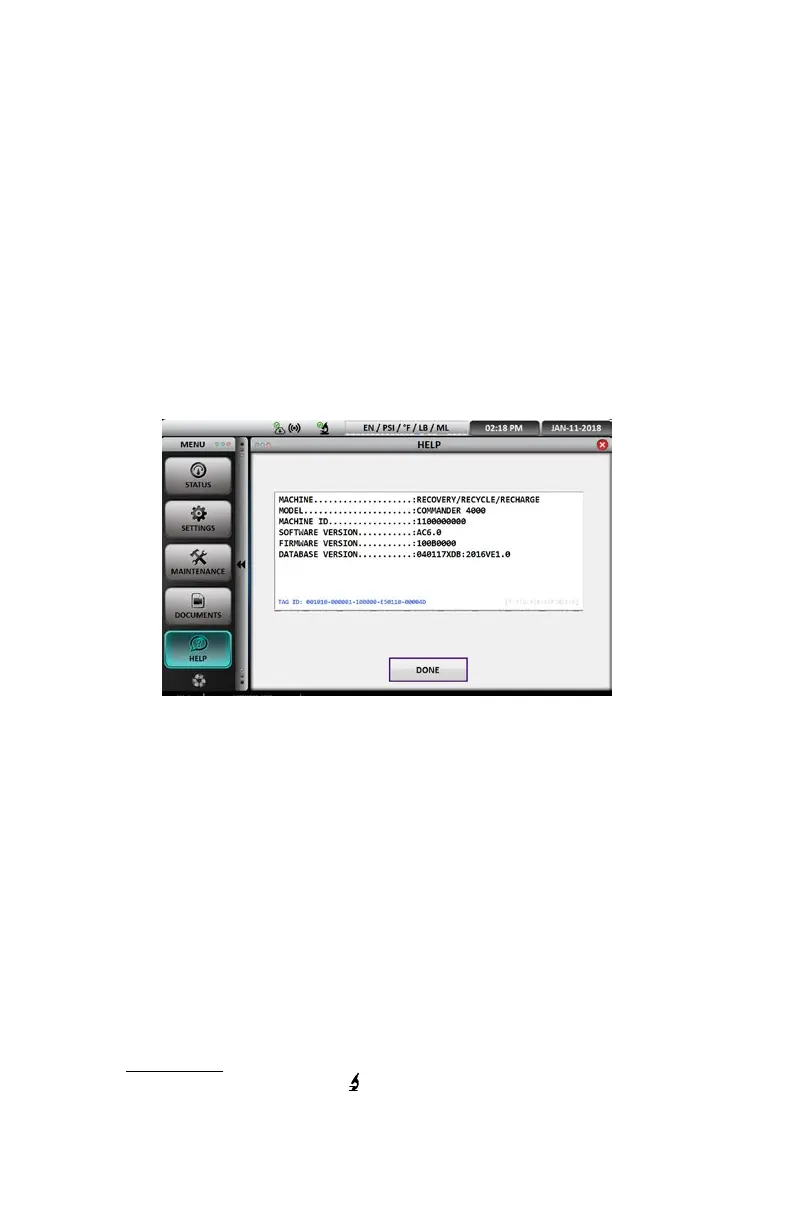

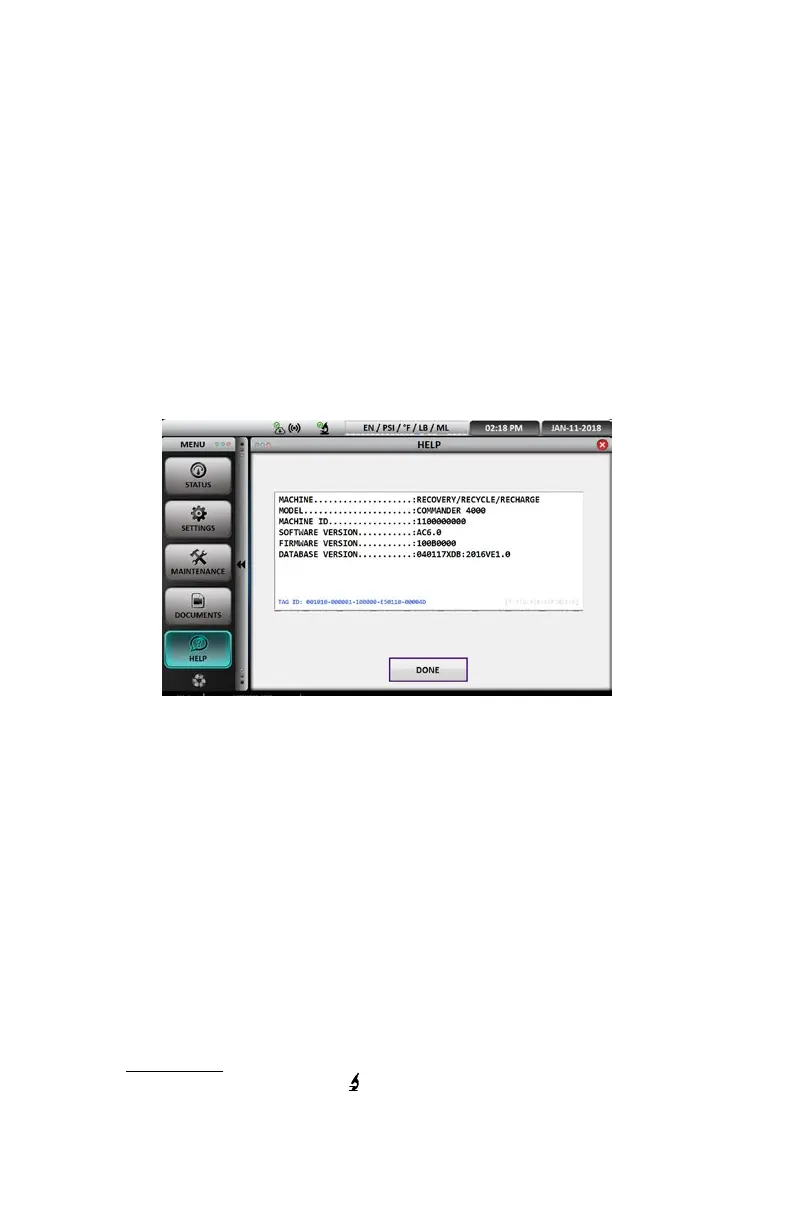

• HELP: The help screen will display all the information about the machine. The machine part

number, brand, model, machine ID, software version, firmware version and database version will be

displayed

VISUAL INDICATOR LIGHTS:

The COMMANDER machines are equipped with visual indicator LED lights to inform on the progress of the

machine.

• RED: No connection between USB and computer command center. Contact customer service

• BLINKING RED: Procedure Alarm. Contact customer service

• YELLOW: No communication between computer command center and PC board. Contact customer

service

• BLINKING YELLOW: User attention needed to perform function displayed on screen

• BLUE: Machine in operation process

• GREEN: Process completed

COMMANDER MACHINE INITIAL SET-UP

• USED OIL BOTTLE: All machines have a used oil bottle, be sure to periodically dispose of the used

oil in an appropriate container

• INTERNAL TANK FILLING:

IDENTIFICATION:

1. Wait for the identifying symbol (

) to appear on the middle top of the screen.

This will take 2-3 minutes

2. Press the small (>>) on the middle left of the screen

3. Select MAINTENANCE

Loading...

Loading...