18 19

model no. 055-6745-2 | contact us 1-800-689-9928

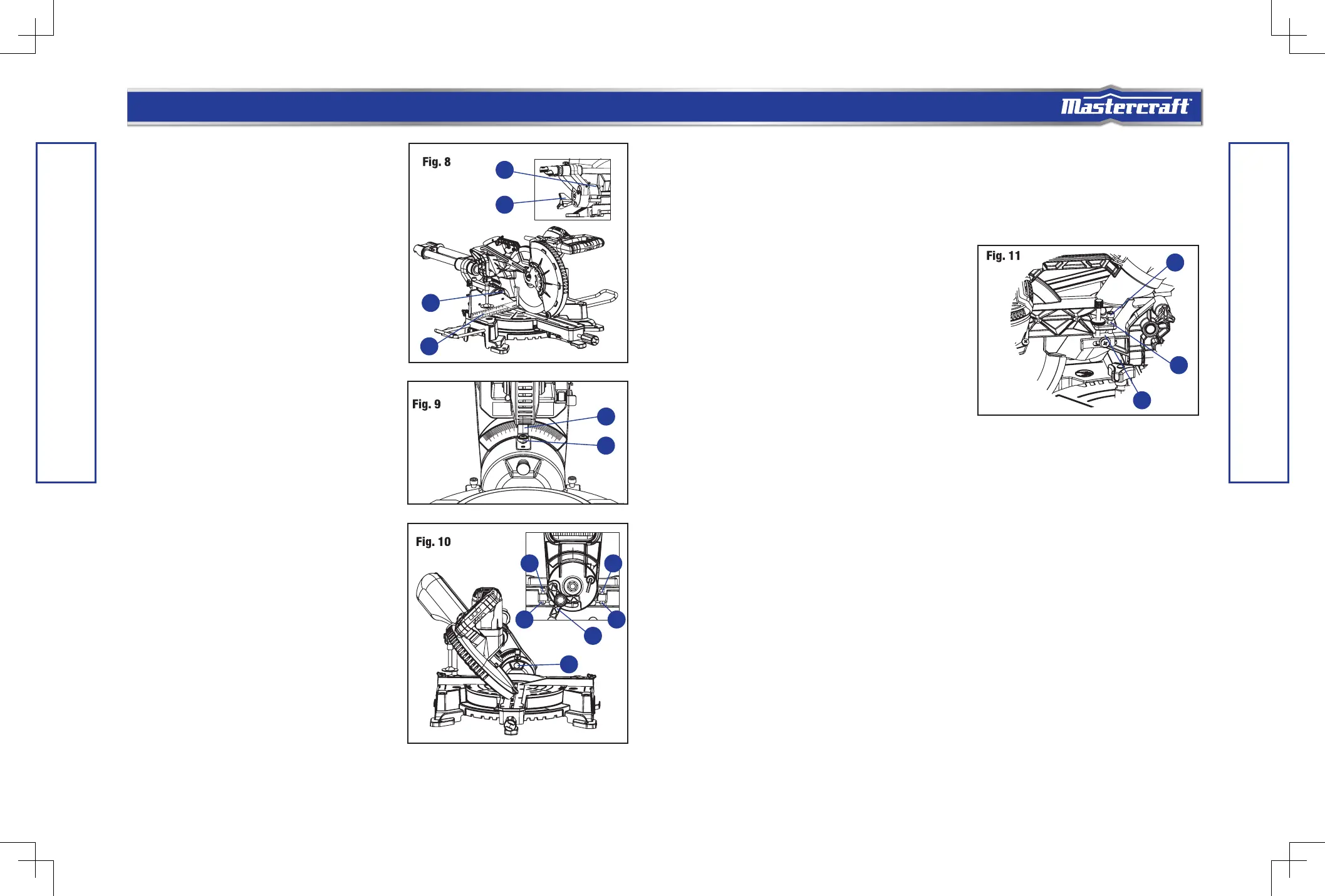

90° (0°) Bevel Adjustment

• Loosen bevel lock knob (1) and push the 0° stop pin

(2) in. Tilt the cutting arm completely to the right.

Tighten the bevel lock knob.

• Place a combination square (3) on the table with the

ruler against the table and the heel of the square

against the saw blade.

• If the blade is not 90° square with the table, loosen

the bevel lock knob, put a 4mm hex wrench into the

hole (4) located in the left side end of the arm holder,

turn the hex screw clockwise or counter-clockwise to

make the blade square to the table.

• Tighten bevel lock knob when alignment is achieved.

90° Bevel Pointer Adjustment

When the blade is exactly 90° to the table, loosen the

bevel indicator screw (1) using a Phillips screwdriver.

• Adjust bevel indicator (2) to the “0” mark on the bevel

scale and retighten the screw.

45° Bevel Adjustment LEFT AND RIGHT

• Loosen the bevel lock knob (1) and tilt the cutting

head completely to the left.

• Pull out the 0º stop pin (2).

• Loosen the bevel lock knob and tilt the cutting head

completely to the left. The mitre angle scale must be

at 0º.

• Using a combination square, check to see if the blade

is at a 45° angle to the table.

• If the blade is not at 45° to the table, tilt the cutting

arm to the right, loosen the lock nut (3) on the bevel

angle adjustment bolt (4) and use a 5 mm hex wrench

to adjust bolt depth in or out to increase or decrease

the bevel angle.

ASSEMBLY AND ADJUSTMENTS

• Tilt the cutting arm to the left to 45° bevel and recheck for alignment.

• Repeat above steps until the blade is at 45° to the table.

• Tighten bevel lock knob and lock nut when alignment is achieved.

• The right bevel 45° adjustment uses the same sequence as the left bevel adjustment, just adjusting

the adjustment bolt to 45° on the right.

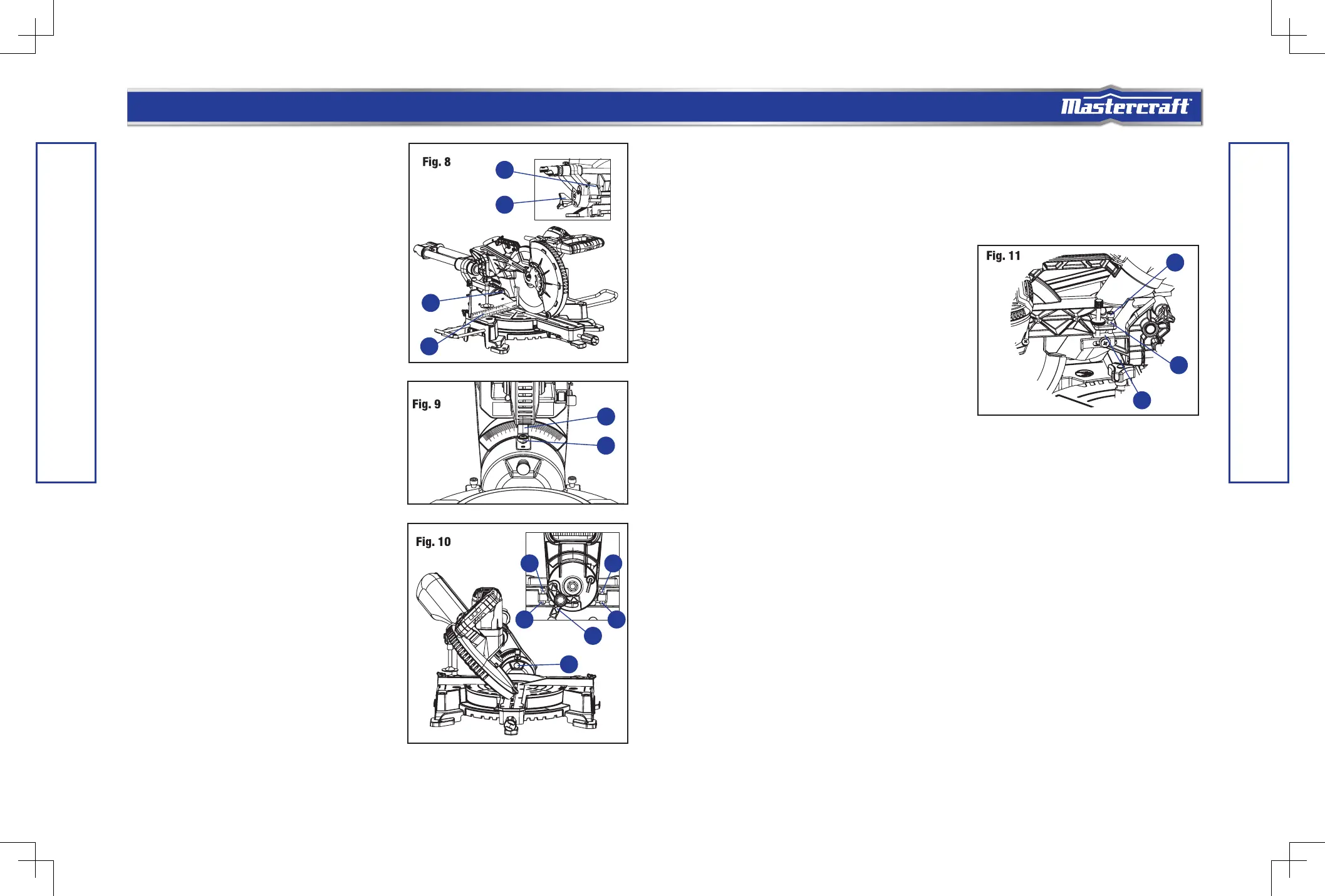

MAXIMUM CUTTING DEPTH

The maximum depth travel of the cutting head was set at

the factory. Check to see that the blade does not extend

more than 11/16” (1.7 cm). below the table insert, and

does not touch the control arm throat or any part of the

base or table. If the maximum depth needs readjusting:

• Loosen the lock nut (1) to free the depth screw (2).

• Move the cutting head down until the blade extends

just 11/16” (1.7 cm). below the table insert.

• Adjust the depth screw to touch the stop plate (3),

then tighten the lock nut to secured the depth screw.

• Recheck the blade depth by moving the cutting head front to back through the full motion of a cut

along the control arm. If the blade touches the inside of the control arm, readjust the setting.

• When it is properly set, tighten the lock nut to lock the depth screw.

ASSEMBLY AND ADJUSTMENTS

1

2

2

1

3

3

1

2

4

3

4

1

4

2

3

Loading...

Loading...