model no. 058-8195-2 | contact us 1-800-689-9928

ASSEMBLY INSTRUCTIONS

ASSEMBLY PREPARATION

8

9

Different materials require different shielding gas when MIG welding. Refer to the set-up chart inside

the wire drive compartment.

Mild steel: Use 75% argon and 25% CO for reduced spatter and reduced penetration for thinner

materials. Use CO for deeper penetration and increased spatter.

Note: Do not use argon gas concentrations higher than 75% on steel. The result will be extremely

poor penetration, porosity, and brittleness of weld.

Stainless steel: Use a mixed gas consisting of helium, argon, and CO .

Aluminum or bronze: Use 100% argon.

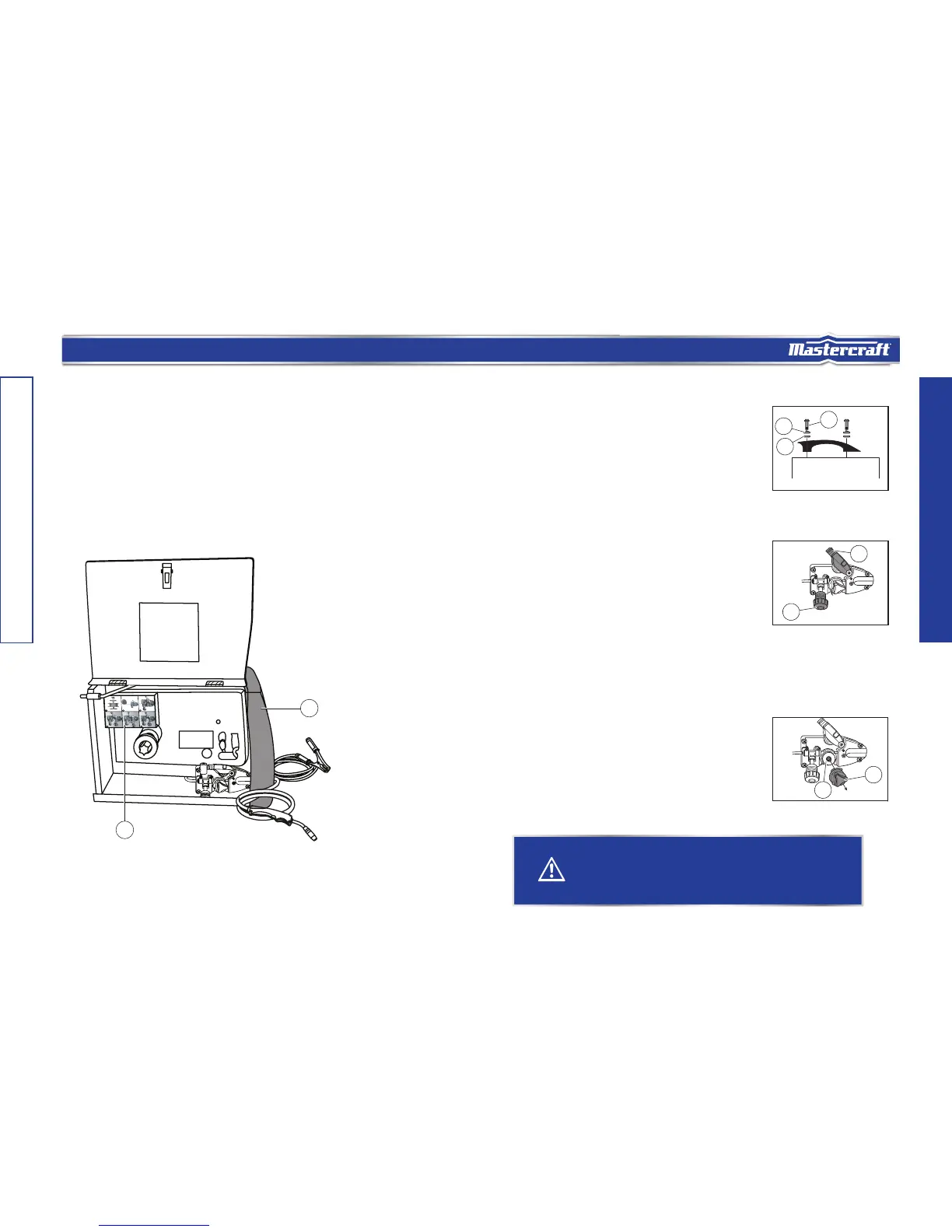

The wire drive compartment houses wire feed components (1) such as wire feeder and spool hub,

and includes a set-up chart (2).

GAS SELECTION

WIRE DRIVE COMPARTMENT

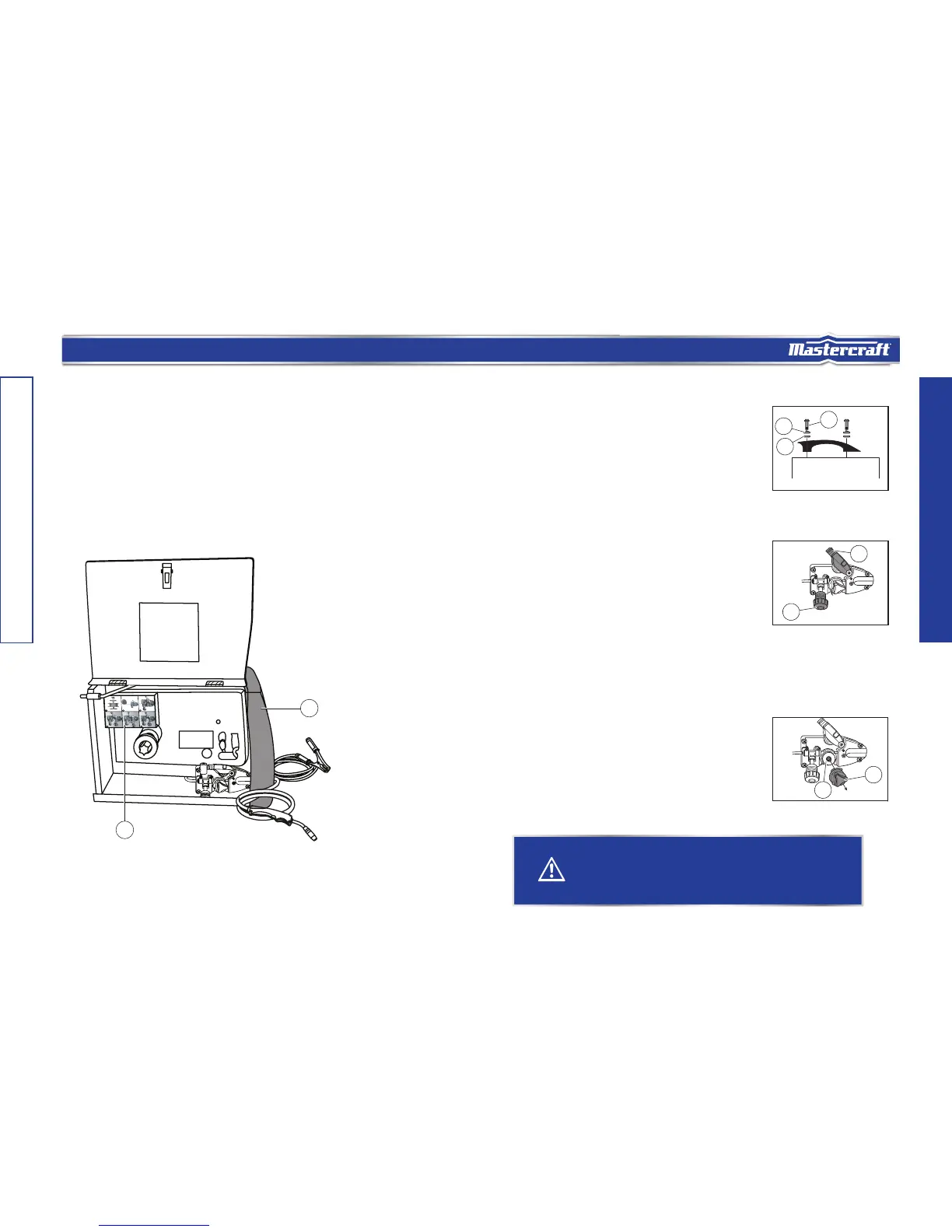

Installing the handle:

Installing the wire roller:

1

2

2

3

MC-588195-02

1

2

1

MC-588195-03

1. Line up the holes in the handle with the

holes on the top of the welder.

2. Place a lock washer (1) and a washer (2)

onto the welder handle screws.

3. Insert a screw with the washers through

the holes on the handle and into the top

of the welder, and tighten the screw

(fig. A).

1. Open the wire drive compartment.

2. Remove the drive tension by loosening

the drive tension adjusting knob (1) and

lifting the drive tension adjustor and

drive tension arm (2) away from the

drive roller (fig. B).

3. Put an end of the wire into the hole on

outside edges of the wire spool and

bend it over to hold the wire in place.

Remove the wire spool from the wire

drive compartment.

4. Rotate the drive roller cap (1)

counter-clockwise and remove it from the

drive roller (2) (fig. C).

WARNING!

-

Note: If the wire is already installed in the welder, roll the wire back onto the wire spool by manually

rotating the wire spool clockwise. Do not allow the wire to come out of rear end of the inlet guide

tube.

6.

0

1

2

MC-588195-04

Loading...

Loading...