WARNING!

Potential hazard that could result in serious injury or

loss of life.

• Do not use if the tool is not in proper working order.

• Do not use oxygen or any other combustible or bottled gas to power

the tool.

• Do not use this tool in the presence of any flammable liquids or gases.

• Always keep the hoses away from heat, oil, and sharp edges. Check

hoses for wear and ensure that all connections are tightened.

• Keep hands and other parts of the body away from

the tool’s discharge and working areas when

connecting it to the air supply.

WARNING!

Potential hazard that could result in serious injury or

loss of life.

Mastercraft® Air-powered Impact

Wrench

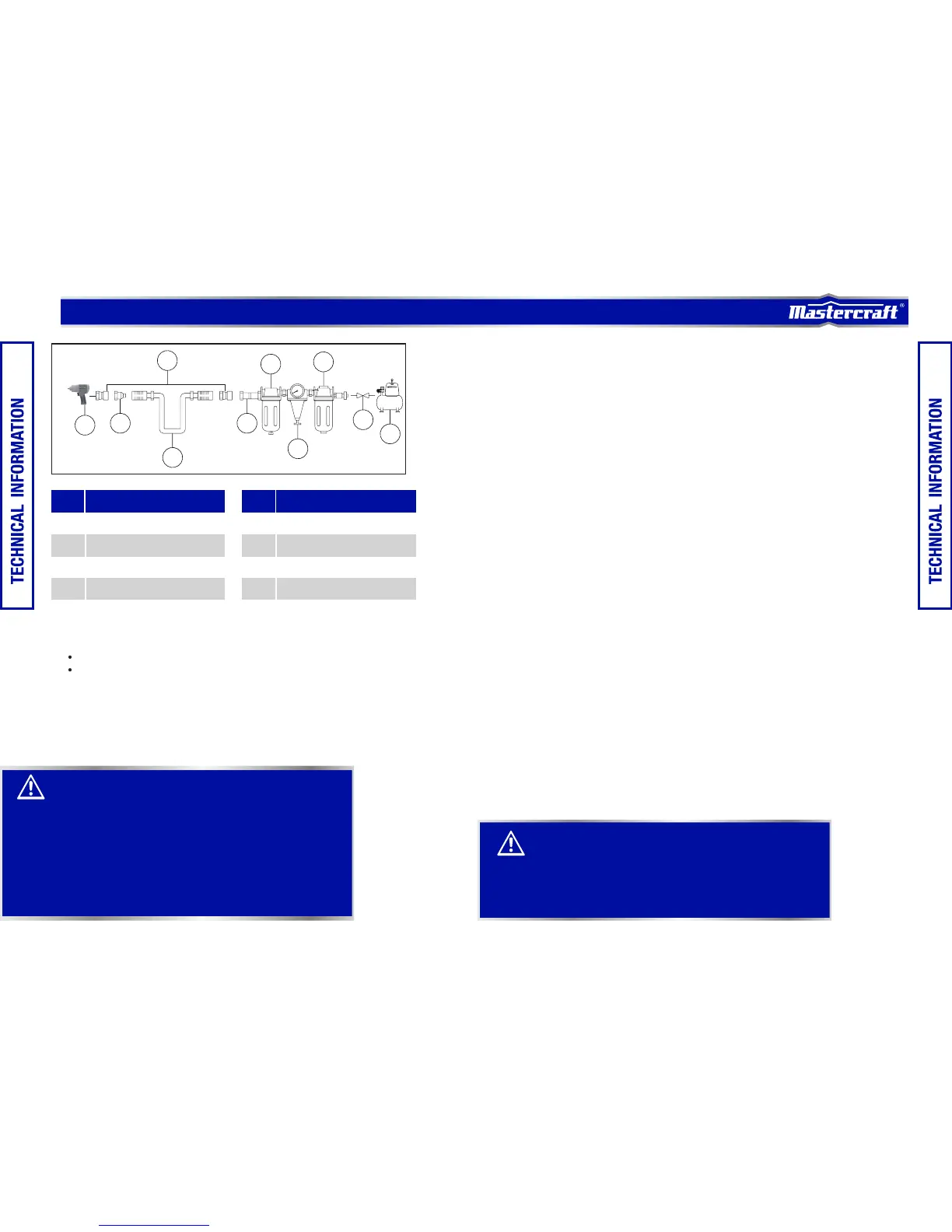

DescriptionNo. No.

6

7

8

9

1

2

3

Regulator 0 -123 PSI( 0-8.5 bar)

Filter

Cut-off valve

Air compressor

Description

2

5

7

1

3

3

6

8

9

4

Quick coupler

Quick connector

Air hose

Lubricator

4

5

12

model no. 058-9803-0 | contact us 1-800-689-9928

Air system

Always use clean, dry, regulated, compressed air at 4.8 to 7.5 bar (70 to 110 PSI).

Do not exceed the maximum or minimum pressures. Operating the tool at the wrong

pressure (too low or too high) will cause excessive noise or rapid wear.

• Always use impact sockets specifically designed for this Air-powered Impact Wrench.

• Ensure that air is supplied at regulated pressure and the air flow is maintained as per

specifications.

• Drain the compressor tank daily. Water in the air line will damage the impact wrench.

• Clean the air inlet filter weekly.

• Increase the line pressure to compensate for an unusual long air hose (longer than 8 m). The

minimum hose diameter (I.D) should be 1/4" (6.4 mm) and the fittings must have the same

inner dimensions.

• It is recommended that an automatic in-line filter-regulator-lubricator be used and be located

as close to the tool as possible. This increases tool life and keeps the tool in good working

order.

• Regularly check the in-line lubricator and fill it with lubricating oil.

• If a filter-regulator-lubricator is not installed, place up to 6 drops of lubricating oil into the air

inlet plug before each use and for every 2 hours of use.

• If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which leads to power reduction, less efficiency, and poor performance

of the tool.

• For proper adjustment of the in-line lubricator, place a sheet of paper next to the exhaust

ports and hold the throttle open for approximately 30 seconds. The lubricator is properly set

when a light stain of oil collects on the paper. Excessive amount of oil should be avoided.

Loading...

Loading...