Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 15/47 07/2014

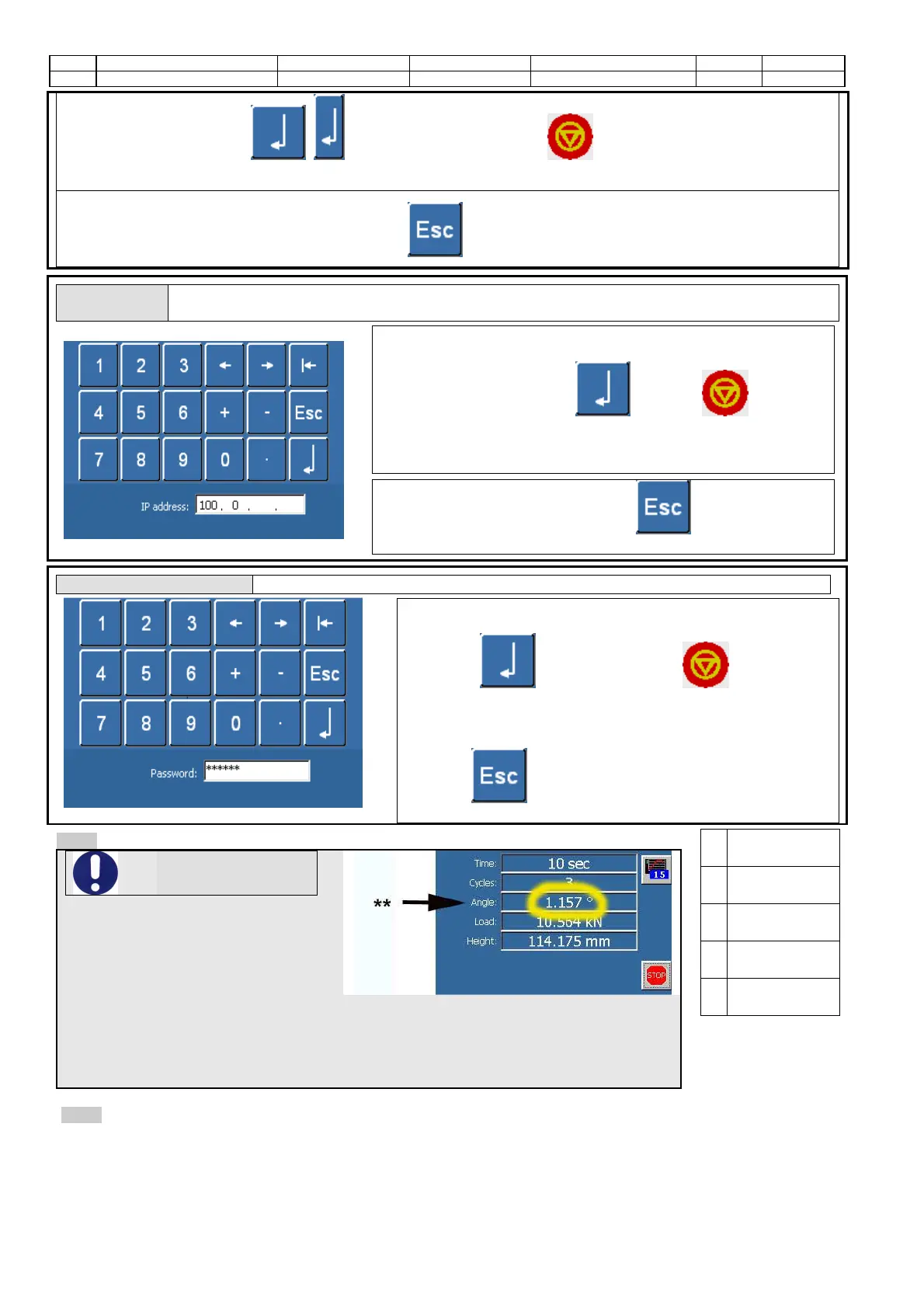

numeric/alphan

umeric value

with the virtual

keyboard.

Touch / or push the confirmation key to confirm the new value; wait for

the closure of the virtual keyboard and for the update of the relevant “parameter” button.

numeric/alphanumeric value with the

virtual keyboard.

Touch and wait for the closure of the virtual keyboard.

ADDRESS

It is visualized when a “parameter” button is activated: the value is shown as an “IP address” on a white

background

How to change

an “IP

address” value

with the virtual

keyboard.

1. Insert the value as “IP address” using the

virtual keyboard.

2. Touch or press to confirm

the new value, then wait for the closure of

the virtual keyboard and the updating of the

relevant “parameter” button.

How to annul the change of

a value shown as ”IP

address” using the virtual

keyboard.

Touch and wait for the

closure of the virtual keyboard.

It is visualized when a function secured by a password is activated.

How to enter a password using the virtual keyboard

1. Enter a password using the virtual keyboard

2. Touch or press the button to confirm the

password. Wait for the activation of the secured function

(correct password) or for the visualization of an error message

(if the password is wrong).

3. Touch to annul the password entry and the activation

of the secured function

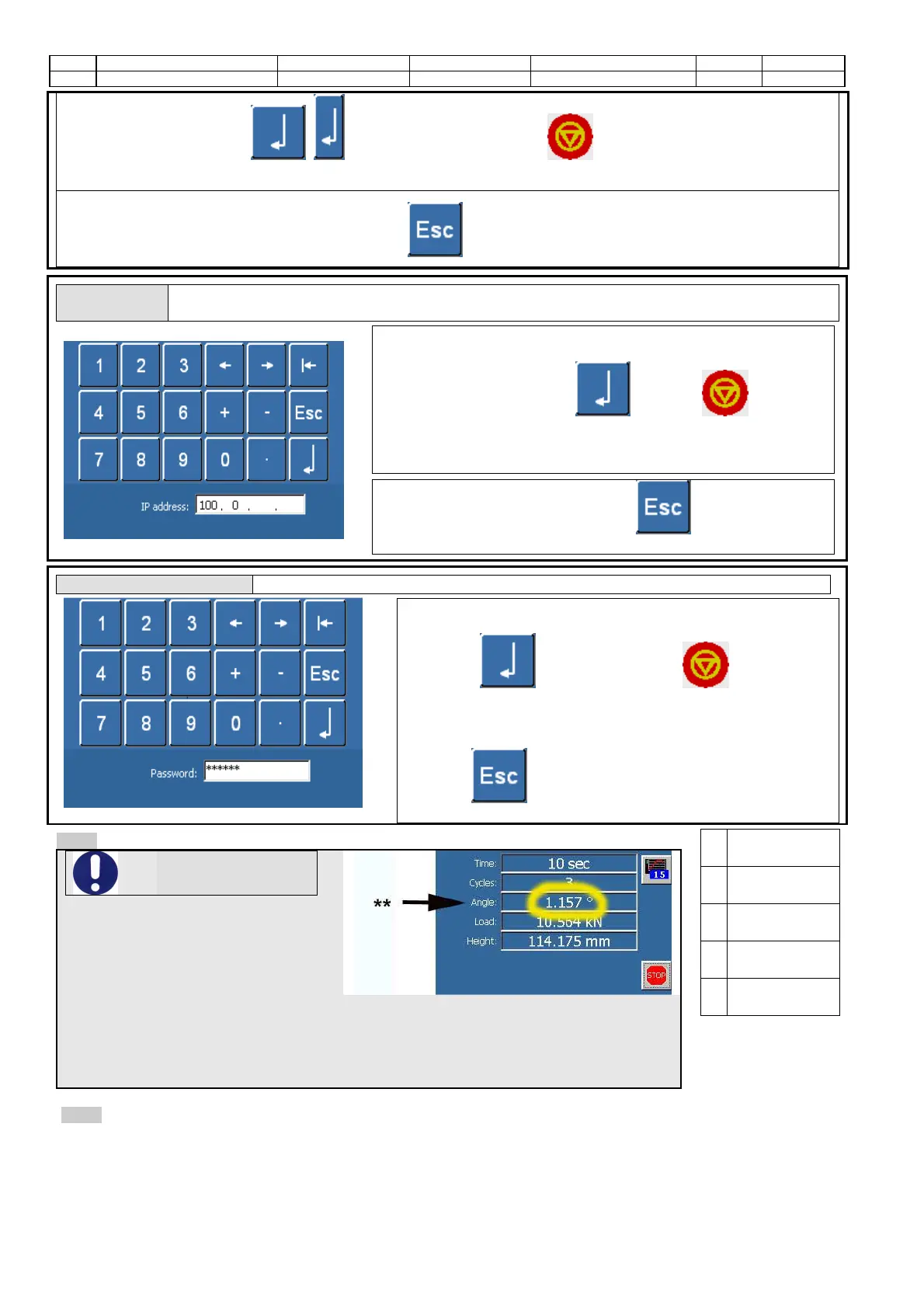

ATTENTION

** N.B.: THE GYRATION ANGLE SHOWN BY

THE DISPLAY AND RECORDED BY THE

MACHINE DURING THE TEST IS THE

EXTERNAL ANGLE USED BY THE

MANUFACTURER TO CALIBRATE THE

MACHINE.

THIS ANGLE HAS A DIFFERENT VALUE FROM THE ONE OF THE INTERNAL ANGLE, AND

THEREFORE THE OPERATOR DOES NOT HAVE TO USE IT.

THE INTERNAL GYRATION ANGLE IS CALIBRATED AT THE FACTORY USING THE “DYNAMIC ANGLE

VARIATION KIT” IN ACCORDANCE TO THE INTERNATIONAL STANDARDS AND CERTIFIED BY A

DOCUMENT SUPPLIED WITH THE MACHINE.

SEE CHAPTER 7.01 CALIBRATION SPECIFICATIONS.

ROTATION

SPEED

NUMBER OF

CYCLES

SPECIMEN

HEIGHT

APPLIED

LOAD

ANGLE OF

ROTATION

Modes of operation: - Compaction of specimen in accordance to the selected number of rotations.

- Compaction of specimen upon reaching the selected height.

- Compaction of specimen upon reaching the selected density.

Loading...

Loading...