Calder Brothers Corporation

Model: M415XT Maintainer

M415XT

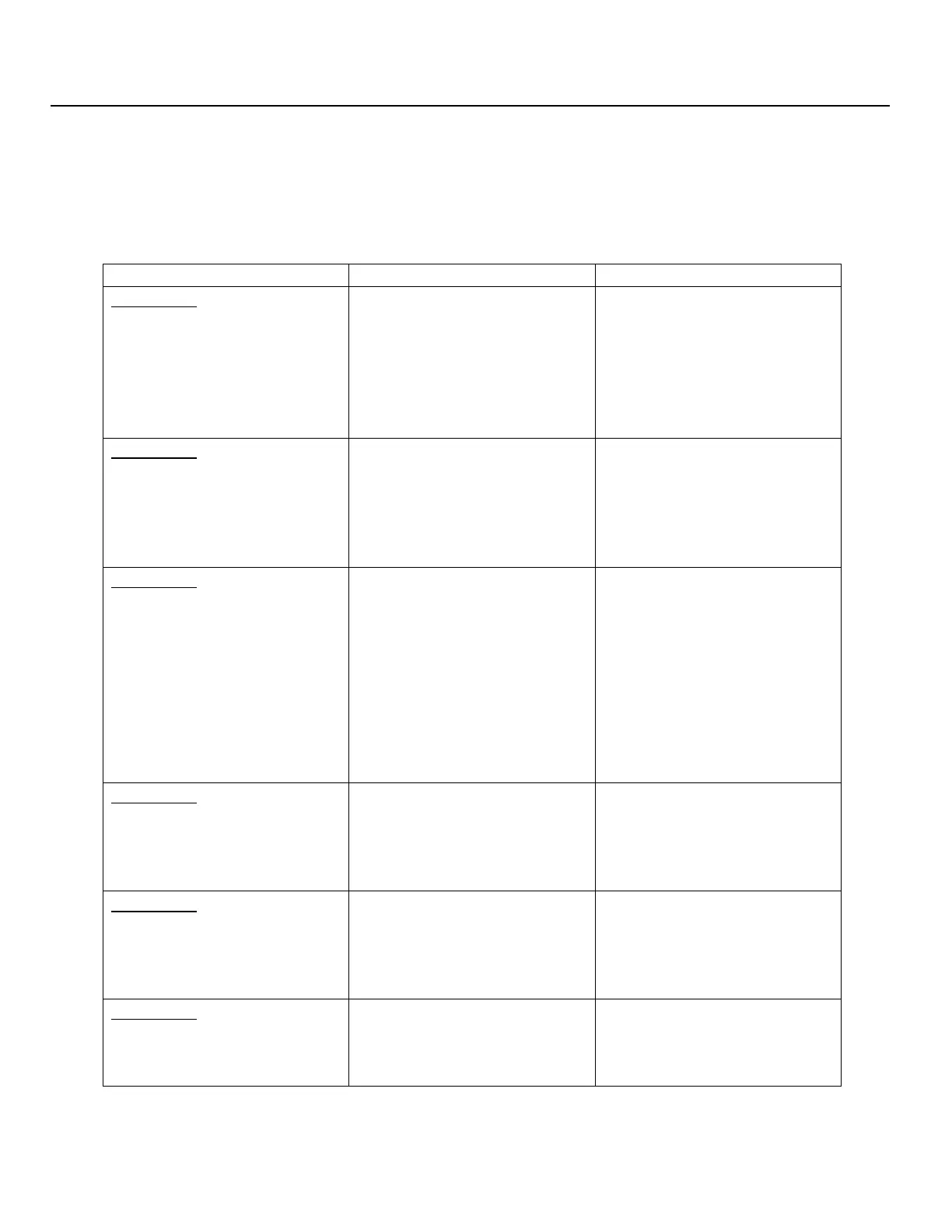

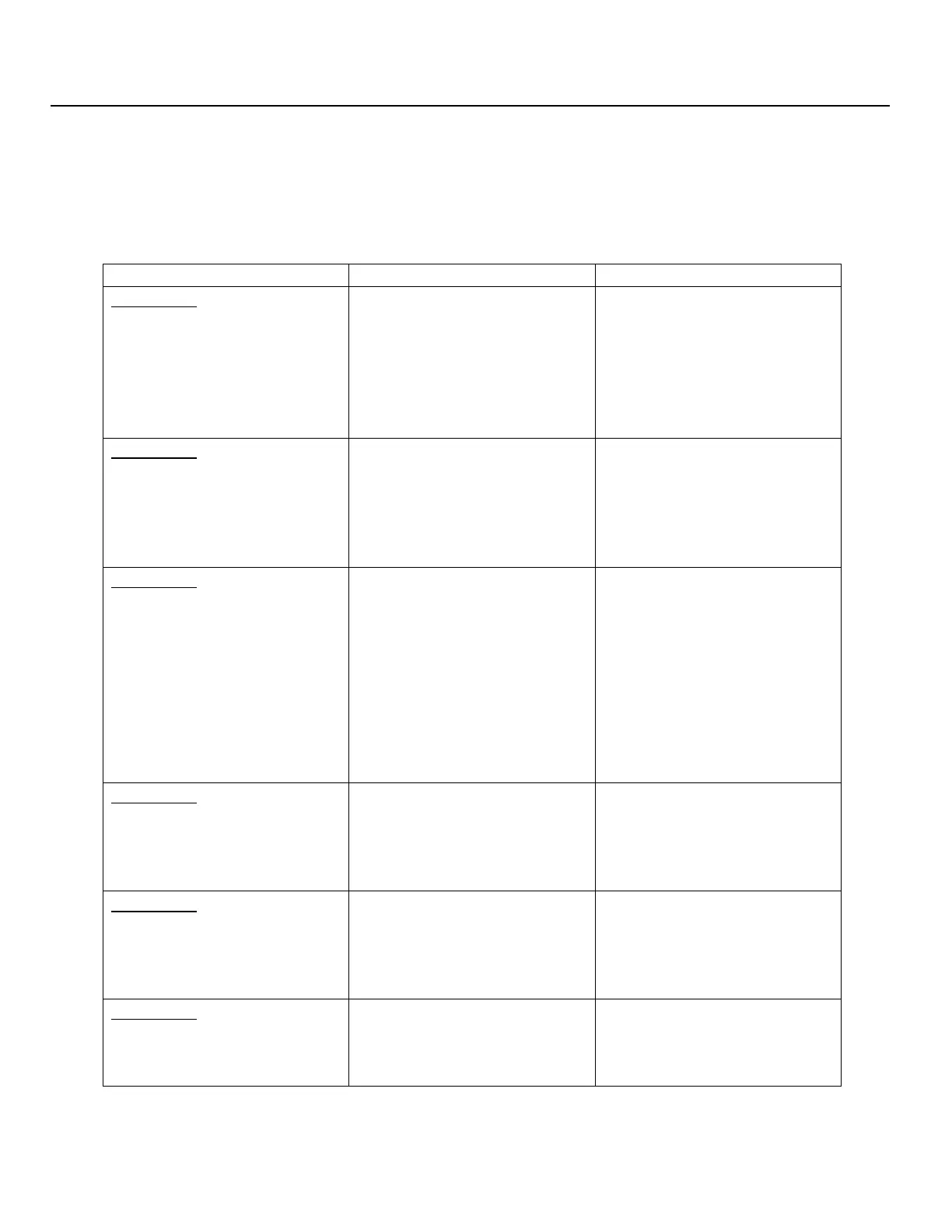

Axle Service

3. TROUBLESHOOTING

3.1.

TROUBLESHOOTING

Breakage towards the

external

end of the gear tooth

greater than expected

2.

Incorrect gear

adjustment (too much

clearance)

3.

Pinion ring nut has come

Replace the bevel gear. Follow

the steps carefully that are

recommended for adjusting

gear tooth and pinion clearance

and for detecting tooth

impression.

Breakage towards the internal

end of the gear tooth

2.

Incorrect gear

adjustment (too little

clearance)

3.

Pinion ring nut has come

Replace the bevel gear. Follow

the steps carefully that are

recommended for adjusting

gear tooth and pinion clearance

and for detecting tooth

Pinion and gear teeth

are worn or scored

1.

Insufficient lubrication

2.

Lubricant is dirty

3.

Wrong lubricant or with

impoverished additives

4.

Pinion bearings are worn,

causing incorrect axial

clearance of the

contact between

gear

Replace the pinion’s

bearings, making sure the

gear, pinion and bearing

preloads are arranged

correctly.

Use the correct lubricant, fill

up to the right level and

change it at the intervals

Pinion and gear teeth

overheated. See if the

colour of the gear teeth has

1.

Prolonged operation at

excessive temperatures.

2.

Wrong lubricant

3.

Low oil level

Replace the bevel gear. Use

the correct lubricant, fill up

to the right level and change

it at the intervals

Pitting of pinion teeth

2.

Insufficient lubrication

Replace the bevel gear. Use

the correct lubricant, fill up

to the right level and change

it at the intervals

Breakage due to fatigue of the

pinion tooth (check for

characteristic fracture lines)

2.

Continuous overload

Loading...

Loading...