Installation and Operational Instructions for

ROBA-stop

®

-S brake Type 856. _ _ _ . _

Sizes 8, 9 and 10 (B.8.3.GB)

03/11/2010 TK/KE/GC/SU Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-0

Eichenstraße 1 Fax: 08341 / 804-421

D-87665 Mauerstetten http://www.mayr.de

Page 12 of 14 Germany E-Mail: info@mayr.de

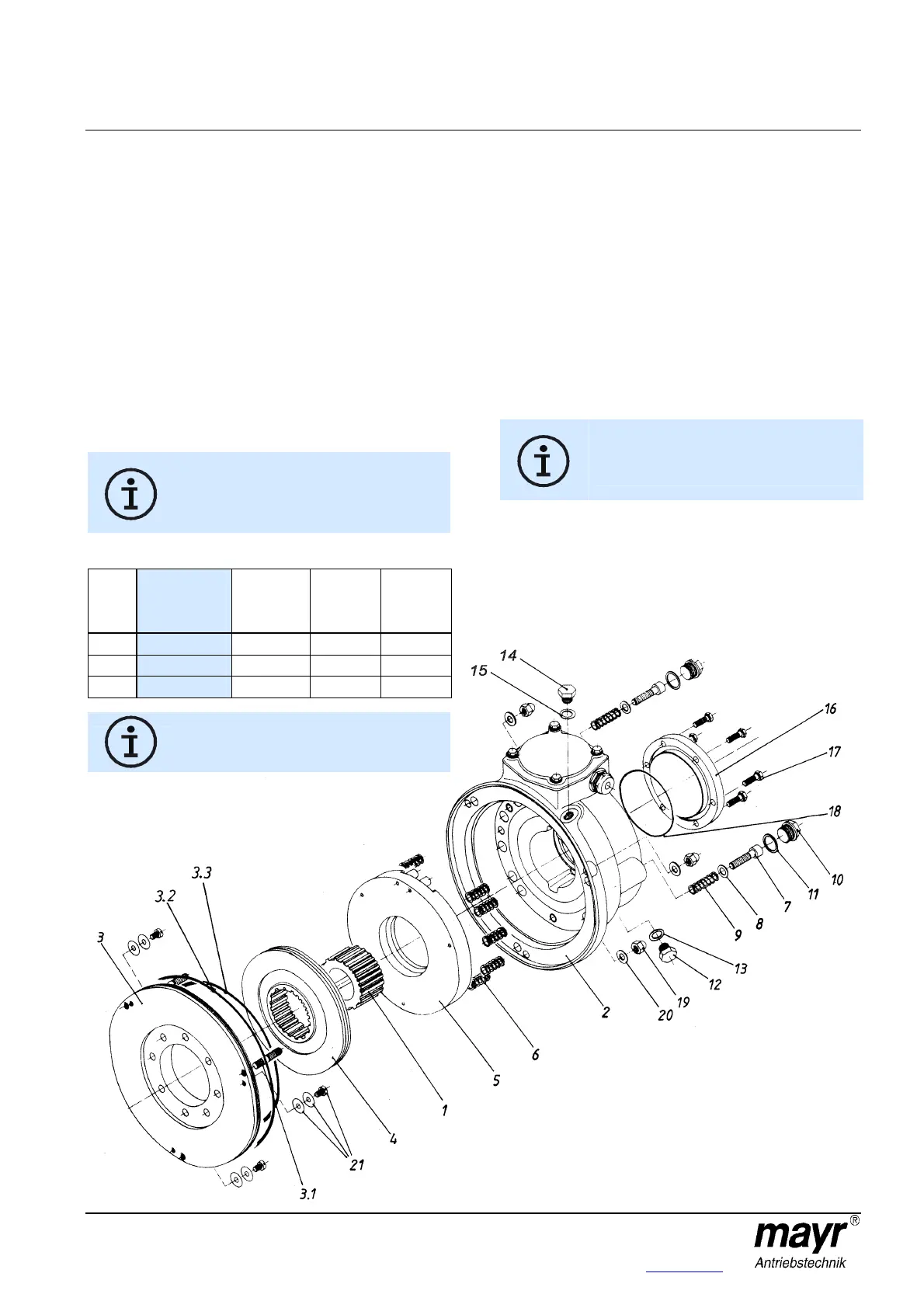

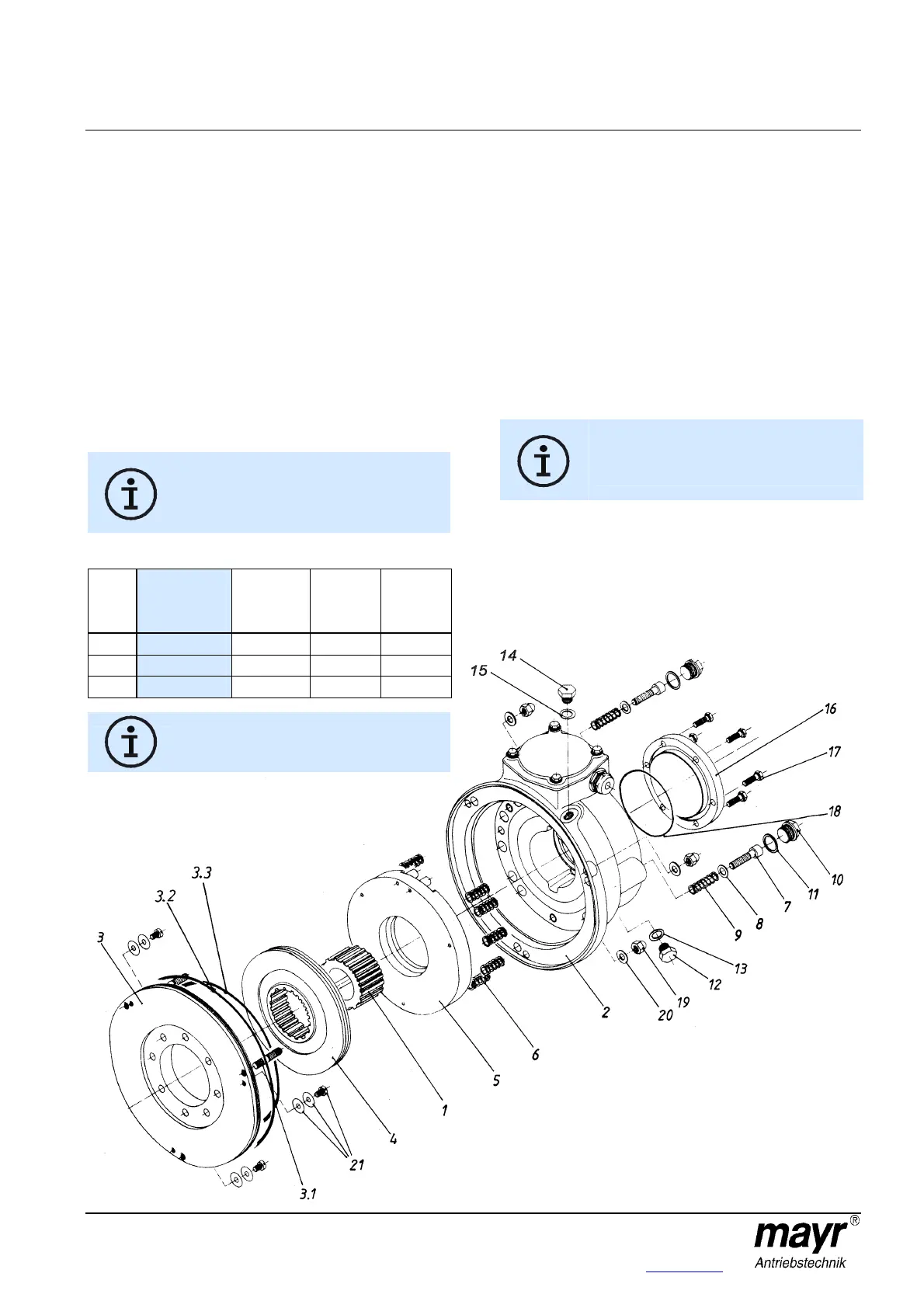

Braking Torque Adjustment (Fig. 14)

Braking torque adjustment is carried out via various thrust spring

(6) assembly variants in the coil carrier (2) acc. Table 2.

Procedural Method:

1. Unscrew the screw plugs (10) inc. the copper sealing rings

(11).

2. Screw in both emergency release screws (7) up to contact

on the coil carrier (2)

3. Loosen the cap nuts (19) inc. the washers (20).

4. Remove the brake from the flange plate (3).

Do not damage the O-rings (3.2 and 3.3)!

5. Remove the emergency release screws (7).

6. Remove the armature disk (5).

7. Remove abraded particles from the rotor and clean the

brake.

Do not use grease or oil.

8. Change the number of thrust springs (6) acc. Table 2.

The thrust springs must be distributed evenly in

the coil carrier (2). Always remove or insert two

springs located opposite each other to make

sure that the armature disk (5) is loaded evenly.

Only use mayr

®

thrust springs!

Table 2: Spring Configuration

Size

Nominal

torque 10

springs

[Nm]

8 springs

[Nm]

6 springs

[Nm]

4 springs

[Nm]

8

100 80 60 40

9

200 160 120 80

10

400 320 240 160

Torque tolerance: +40 % / -20 %

Further spring configurations or braking torques

on request.

9. Insert the armature disk (5).

Please make sure that the two pins for actuating the

microswitch situated next to each other protrude into the

terminal box.

10. Screw both emergency release screws (7) into the armature

disk (5) up to contact on the coil carrier (2).

If necessary, push the armature disk lightly onto the coil

carrier, so that the emergency release screws can be joined.

11. Push the brake over the stud screws (3.1) and join it with the

flange plate (3).

Do not damage the O-rings (3.2 and 3.3)!

12. Screw on the brake using the cap nuts (19) and the washers

(20).

Do not tilt!

Observe the tightening torque acc. Table 1!

13. Important!

Unscrew both emergency release screws (7) in

the armature disk (5).

Unscrew the screws, but do not remove them.

14. Screw the screw plugs (10) inc. the copper sealing rings

(11) back in. The emergency release screws (7) are spring

applied.

Fig. 14

Loading...

Loading...