Installation and Operational Instructions for

ROBA-stop

®

-S brake Type 856. _ _ _ . _

Sizes 8, 9 and 10 (B.8.3.GB)

03/11/2010 TK/KE/GC/SU Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-0

Eichenstraße 1 Fax: 08341 / 804-421

D-87665 Mauerstetten http://www.mayr.de

Page 7 of 14 Germany E-Mail: info@mayr.de

Brake Attachment

1. Loosen the cap nuts (19) and remove the washers (20).

2. Remove the flange plate (3) from the brake by lightly tapping

the stud screws (3.1) with a plastic hammer.

3. Screw the flange plate (3) onto the motor bearing shield or

onto the machine wall (sealing must be carried out customer-

side; if there are any questions concerning sealing, please

contact the manufacturers).

4. Mount the gear hub (1) onto the shaft, bring it into the correct

position (the length of the key should lie over the entire hub)

and secure it axially (e.g. using a locking ring).

5. Push the rotor (4) by hand onto the gear (1).

Check that the toothing moves easily.

Do not cause any damage!

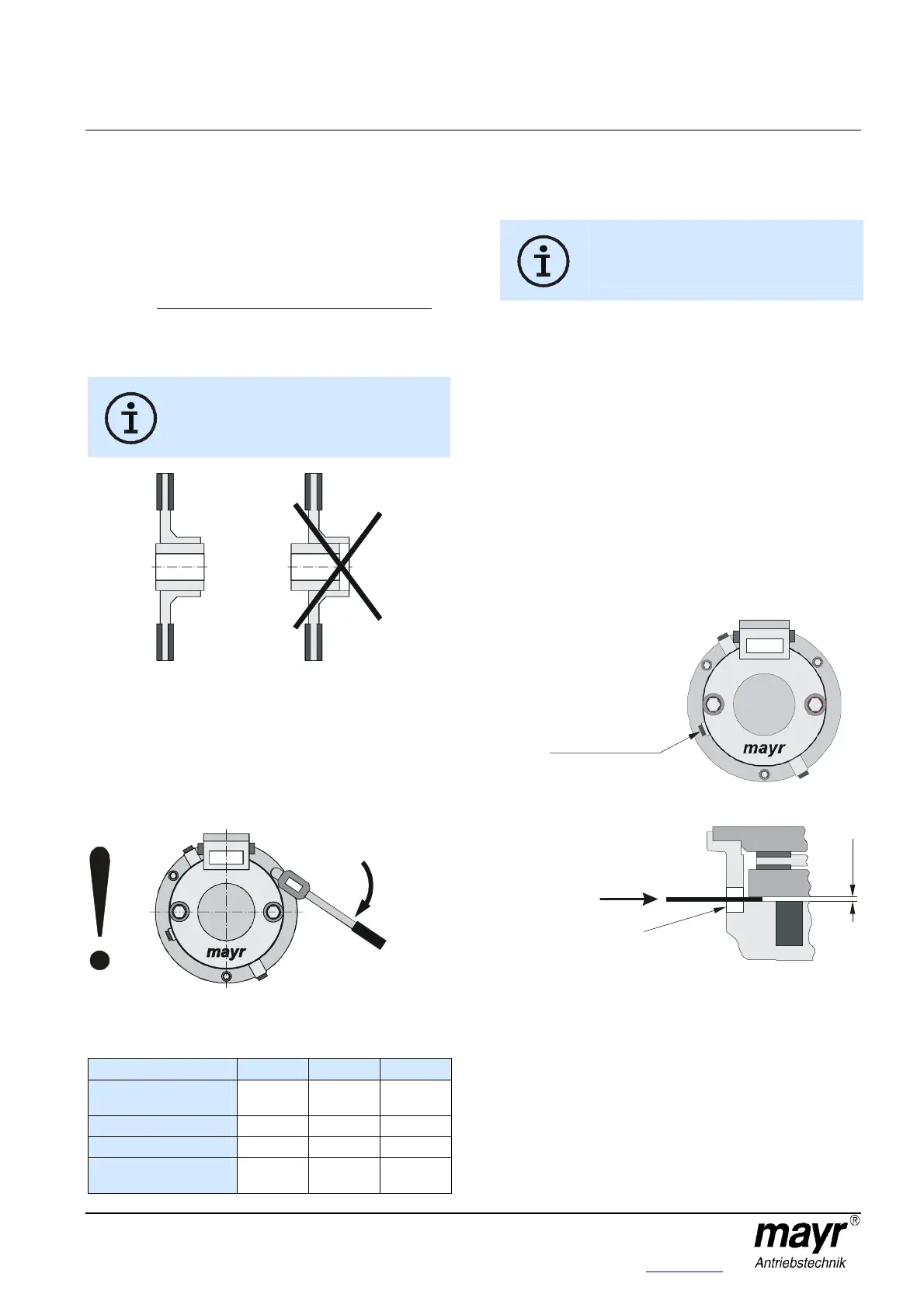

The rotor (4) must be placed onto the hub (1)

so that the toothing remains engaged even

after wear on the friction linings (Fig. 6).

Fig. 6

6. Push the brake over the stud screws (3.1) and join it with the

flange plate (3).

Do not damage the O-rings (3.2 and 3.3)!

7. Screw on the brake using the cap nuts (19) and the washers

(20). Do not tilt!

Observe the tightening torque acc. Table 1!

Fig. 7

Table 1

Size 8 9 10

Tightening torque for

cap nuts (19) [Nm]

13

26

26

Nominal air gap [mm]

0,20

+0,25

0,25

+0,25

0,25

+0,25

Max. air gap [mm]

0,75 1,0 1,1

Min. air gap for

re-adjustment [mm]

0,65 0,8 0,8

8. Unscrew the screw plugs (10) inc. the copper sealing rings

(11).

9. Important!

Unscrew both emergency release screws (7) in

the armature disk (5).

Unscrew the screws, but do not remove them.

10. Screw the screw plugs (10) inc. the copper sealing rings (11)

back in. The emergency release screws (7) are spring

applied.

11. Check the air gap acc. section "Air Gap Inspection".

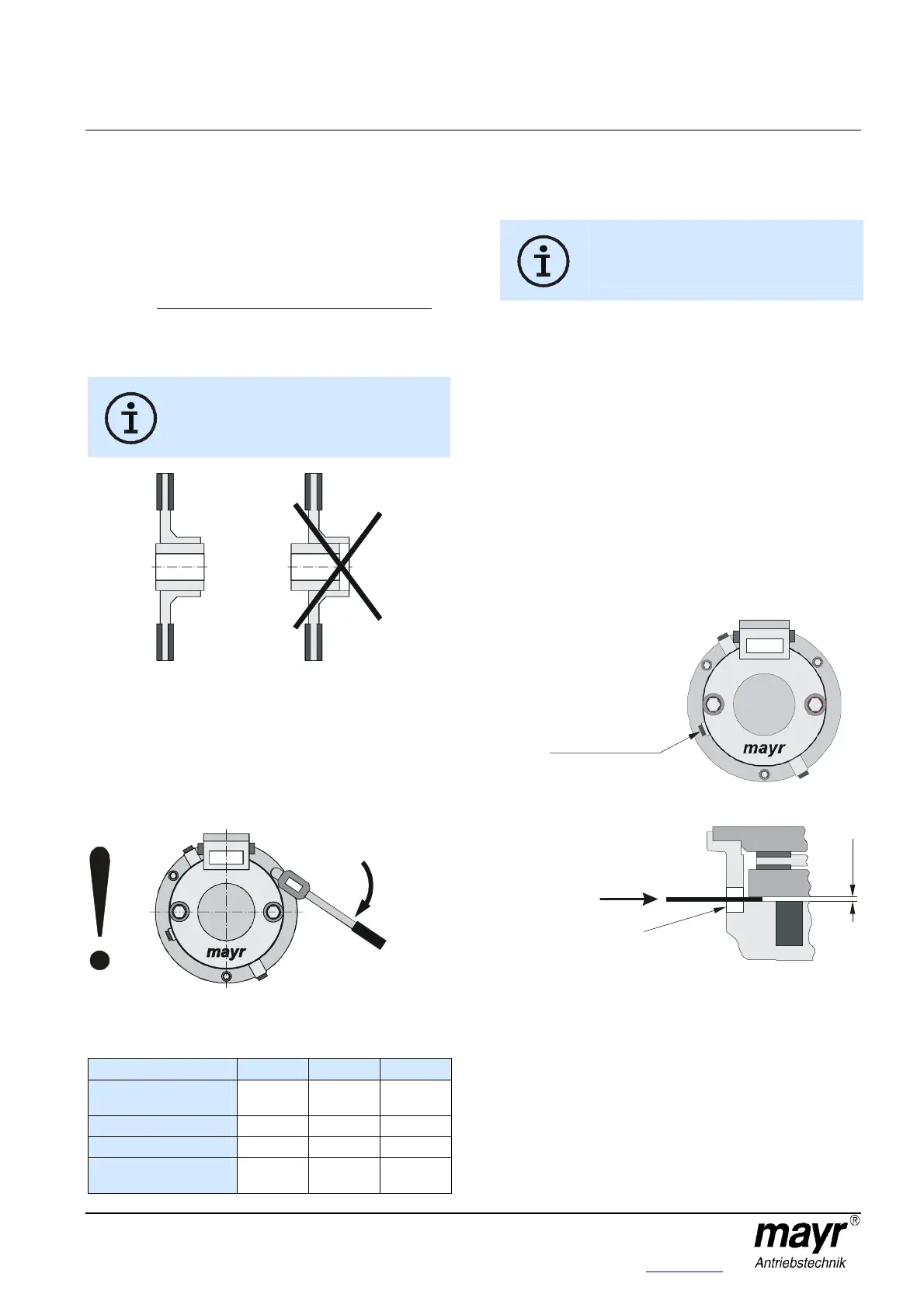

Air Gap Inspection (Figs. 8 and 9)

Due to wear on the friction linings, the air gap between the coil

carrier (2) and the armature disk (5) increases.

The wear condition of the rotor (4) can be monitored in regular

air gap inspections.

Air gap inspection on a de-energised brake.

Air gap inspection on a de-energised brake:

1. Unscrew the screw plug (12) inc. the copper sealing ring (13).

2. Check the air gap by means of a feeler gauge.

The air gap must lie between the nominal air gap and the

max. air gap. Once the max. air gap has been reached, the

air gap must be re-adjusted (see Table 1).

Fig. 8

Fig. 9

Air gap

inspection opening

inspection opening

Feeler gauge

Loading...

Loading...