IM 439 / Page 5 of 24

Air Balancing

All units are supplied with a variable pitch motor sheave to aid

in airflow adjustment. They are typically set at the low end of

the rpm range for field adjustment to the required airflow.

When the final adjustments are complete, the current

draw of the motors should be checked and compared to the

full load current rating of the motors. The amperage must not

exceed the service factor stamped on the motor nameplate.

Upon completion of the air balance, it is a common

industry recommendation that the variable pitched motor

sheave be replaced with a properly sized fixed sheave. A

matching fixed sheave will provide longer belt and bearing

life and vibration free operation. Initially, it is best to have a

variable pitched motor sheave for the purpose of air balancing,

but once the balance has been achieved, fixed sheaves

maintain balancing and alignment more effectively.

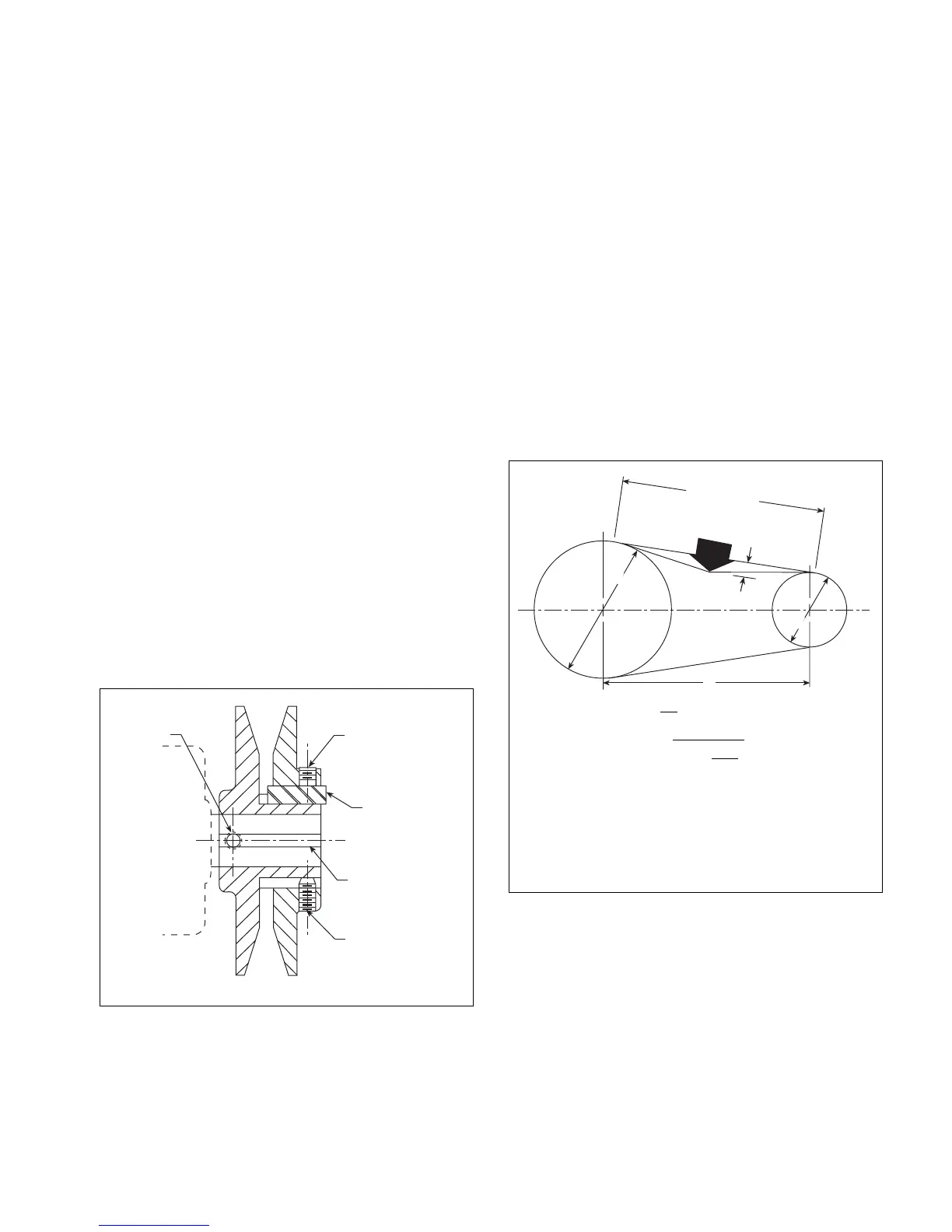

Adjustment (See Figure 6)

1. All sheaves should be mounted on the motor or driving

shaft with the setscrew “A” toward the motor.

2. Be sure both driving and driven sheaves are in alignment

and that shafts are parallel.

3. Fit internal key “D” between sheave and shaft, and lock

setscrew “A” securely in place.

Adjusting:

1. Loosen setscrews “B” and “C” in moving parts of sheave

and pull out external key “E”. (This key projects a small

amount to provide a grip for removing.)

2. Adjust sheave pitch diameter for desired speed by open-

ing moving parts by half or full turns from closed position.

Do not open more than five full turns.

3. Replace external key “E” and securely tighten setscrews

“B” over key and setscrews “C” into keyway in fixed half of

the sheave.

Figure 6.

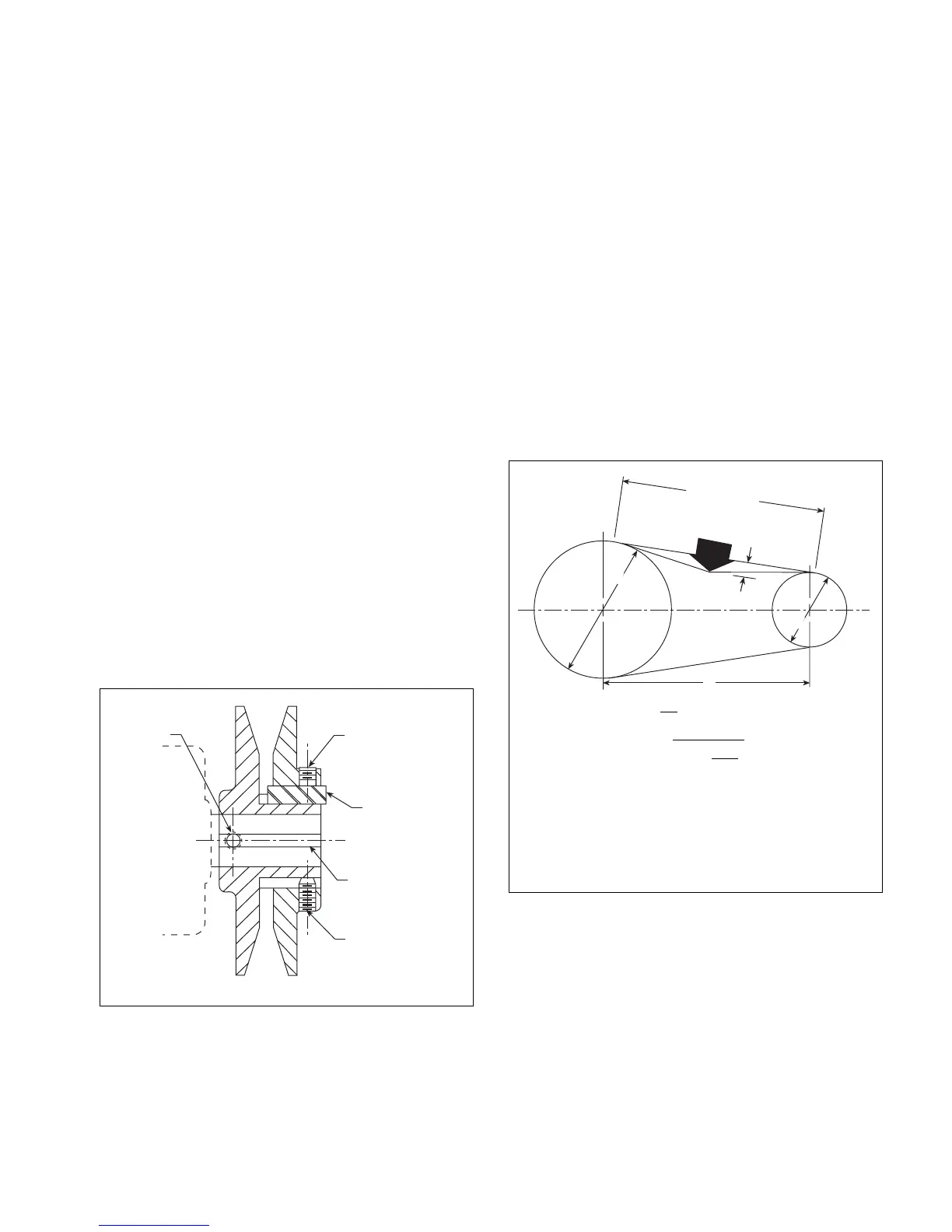

Figure 7. Drive belt adjustment

“E”

“B”

“D”

“C”

“A”

Single Groove

Key “E” projects to

provide a grip for

removing.

h=

t

64

t= C

2

–

D-d

√

2

()

Where:

t= Span length, inches (mm)

C= Center distance, inches (mm)

D= Larger sheave diameter, inches (mm)

d= Smaller sheave diameter, inches (mm)

h= Deflection height, inches (mm)

Note: The ratio of deflection to belt span is 1:64.

Deflection

Force

h

D

d

Span Length (t)

C

4. Put on belts and adjust belt tension to 4 lbs. ± 0.7 lbs.

(18 ± 3N) for a

1

⁄2" to

3

⁄4" (13 mm to 19 mm) belt deflection

height.

5. To determine the deflection distance from normal position,

use a straightedge or stretch a cord from sheave to sheave

to use as a reference line. On multiple-belt drives an adjacent

undeflected belt can be used as a reference.

6. Future adjustments should be made by loosening the belt

tension and increasing or decreasing the pitch diameter

of the sheave by half or full turns as required. Readjust belt

tension before starting drive.

7. Be sure that all keys are in place and that all setscrews are

tight before starting drive. Check setscrews and belt tension

after 24 hours service.

8. When new V-belts are installed on a drive, the initial

tension will drop rapidly during the first few hours. Check

tension frequently during the first 24 hours of operation.

Subsequent retensioning should fall between the mini-

mum and maximum force.

Loading...

Loading...