IM 439 / Page 3 of 24

Note: Installation and maintenance are to be performed only

by qualified personnel who are familiar with local

codes and regulations, and are experienced with this

type of equipment.

Sharp edges are a potential injury hazard. Avoid contact with

them.

Transportation and Storage

Upon receipt of the equipment, check unit for visible dam-

age. Make a notation on the shipper’s delivery ticket before

signing. If there is any evidence of rough handling, the

cartons should be opened at once to check for concealed

damage. If any damage is found, notify the carrier within 48

hours to establish your claim and request their inspection

and a report. The Warranty Claims Department should then

be contacted.

Do not stand or transport the machines on end. For storing,

each unit must be in the “up” position.

In the event that elevator transfer makes upended position-

ing unavoidable, absolutely ensure that the machine is in the

normal upright position for at least 24 hours before operating.

Temporary storage at the jobsite must be indoors, com-

pletely sheltered from rain, snow, etc. High or low tempera-

tures naturally associated with weather patterns will not

harm the conditioners. Excessively high temperatures 140°F

(60°C) may deteriorate certain plastic materials and cause

permanent damage. In addition, the solid-state circuit boards

may experience operational problems.

Installation

General

1. To prevent damage, this equipment should not be oper-

ated for supplementary heating and cooling during the

construction period.

2. Inspect the shipping label for any specific tagging numbers

indicated per request from the installing contractor. At this

time the voltage, phase and capacity should be checked

against the plans.

3. Check the unit size against the plans to be sure that the unit

will be installed in the correct location.

4. After removing the packaging material, remove unit from

the skid.

5. Before installation, check the available dimensions versus

the dimensions of the unit.

6. Pay attention to the location and routing of water piping,

condensate drain piping, and electrical wiring. The loca-

tions of these items are clearly marked on submittal

drawings.

7. The installing contractor will find it beneficial to confer with

piping, sheetmetal, ceiling and electrical foremen together

before installing any conditioners.

Note: Check the unit name plate for correct voltage with the

plans before installing the equipment. Also, make sure

all electrical ground connections are made in accor-

dance with local code.

8. We recommend that the contractor cover the conditioners

with plastic film to protect the machines during finishing of

the building. This is important if spraying fireproofing

material on bar joists, sandblasting, spray painting and

plastering operations have not been completed.

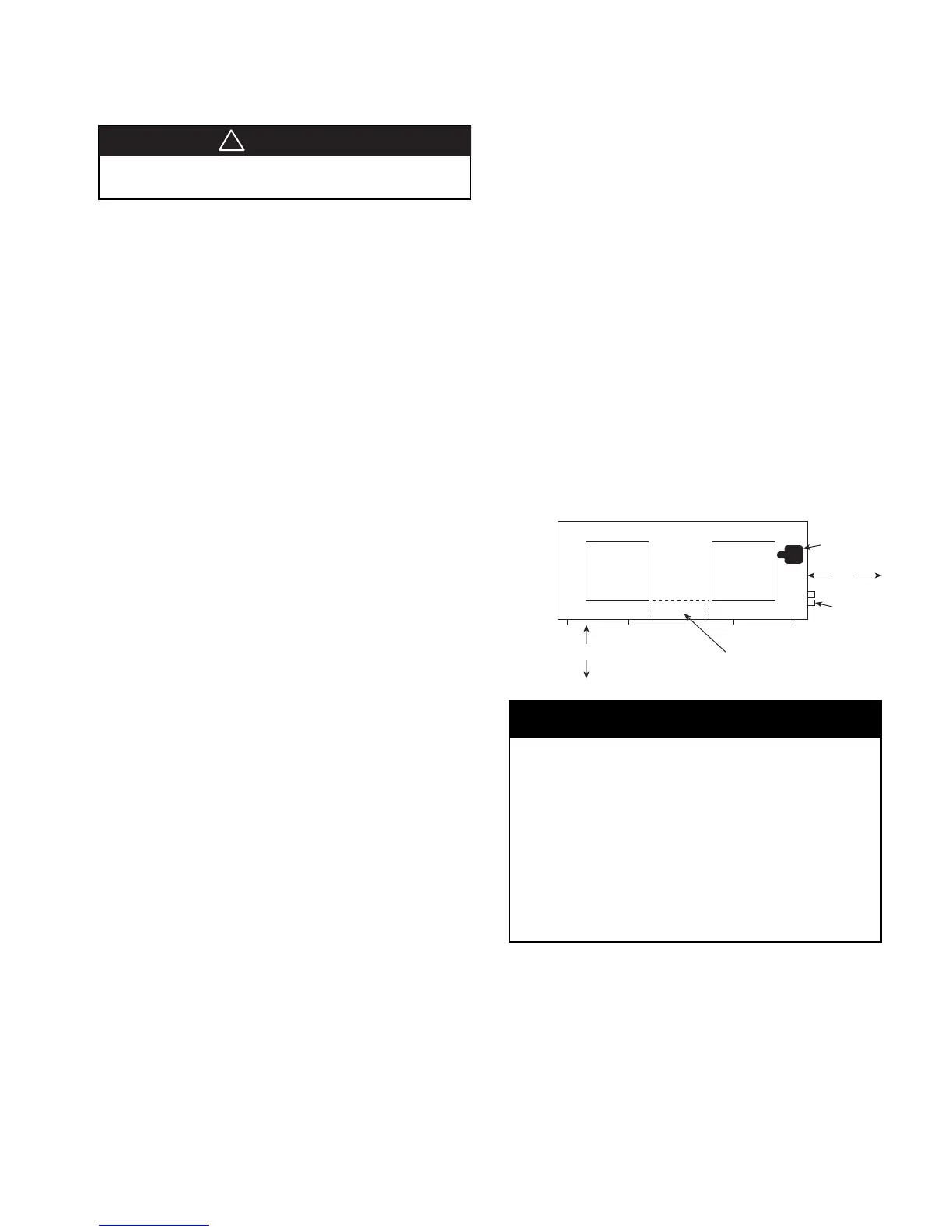

Control Box

Location

Piping

Location

Fan Motor

24"

(610 mm)

Side B

Side A

24" (610 mm)

Figure 1. Service clearance

1. A 24" (610 mm) minimum clearance is required on the

return air, control box and piping sides. However, a 36"

(914 mm) clearance allows for easier serviceability.

2. A 12" (305 mm) minimum clearance is required on Side

A to gain access to panel to remove locking collar for shaft

removal.

3. A 6" (152 mm) clearance is required on Side B to remove

screws holding top panel.

4. Top clearance is required for fan shaft removal.

5. Some codes dictate a 60" (1524 mm) clearance above

the control box which could be violated with a ducted

return. Check your codes.

Unit Location

1. Locate the unit in an area that allows for easy removal of

the filter and access panels, and has enough space for

service personnel to perform maintenance or repair. Pro-

vide sufficient room to make water, electrical and duct con-

nections

(see Figure 1 for service clearance details)

.

2. The contractor should make sure that access has been

provided including clearance for 2" (51 mm) thick filter brack-

ets, duct collars and fittings at water and electrical connec-

tions.

3. Allow adequate room around the unit for a condensate trap.

4. The unit can be installed “free standing” in an equipment

room. Generally, the unit is located in a separate room with

the non-ducted return air facing the return air intake. Alter-

natively, the unit can have a ducted return air.

5. It is recommended that the unit be located on vibration iso-

lators to reduce any vibration

(see Figure 3)

.

6. If optional field installed controls are required (Boilerless

System), space must be provided for the enclosure to mount

on the side of the unit.

CAUTION

!

IMPORTANT

Loading...

Loading...