41

Application Information M5MSY-2010

VACUUMING AND CHARGING

Purging the piping and the indoor unit

Except for the outdoor unit which is pre-charged with

refrigerant R410A, the indoor unit and the refrigerant

connection pipes must be air-purged because the air

containing moisture that remains in the refrigerant

cycle may cause malfunction of the compressor.

Make sure all pipes are connected securely to the

outdoor and indoor valves.

Remove the caps from the fl are valves and the

service. Take note that there are a total of two

service ports for 5MSY20BR, three service ports for

5MSY25BR and four service ports for 5MSY30BR.

Connect the center of the charging gauge to the

vacuum pump.

Connect the charging gauge to the 3-way valve’s

service port. (The numbers of service ports depend

on the O/D unit model).

Start the vacuum pump. Evacuate for approximately

30 minutes. The evacuation time varies with different

vacuum pump capacity. Confi rm that the charging

gauge needle has moved towards -760mmHg.

Proceed to the next 3-way valve and repeat the

steps above.

•

•

•

•

•

•

0

CAUTION

If the gauge needle does not move towards -

760mmHg, be sure to check for gas leaks (using

the refrigerant detector) at fl are type connection

of the indoor and outdoor unit and repair the leak

before proceeding to the next step.

Close the valve of the charging gauge and stop the

vacuum pump.

On the outdoor unit, open the suction valve (3-way)

and liquid valve (2-way) (in anti-clockwise direction)

with 4mm key for hexagon sacked screw.

•

•

•

Allen key

Service port

Flare nut

Outdoor unit 3 way valve

Refrigerant piping

Hi

Low

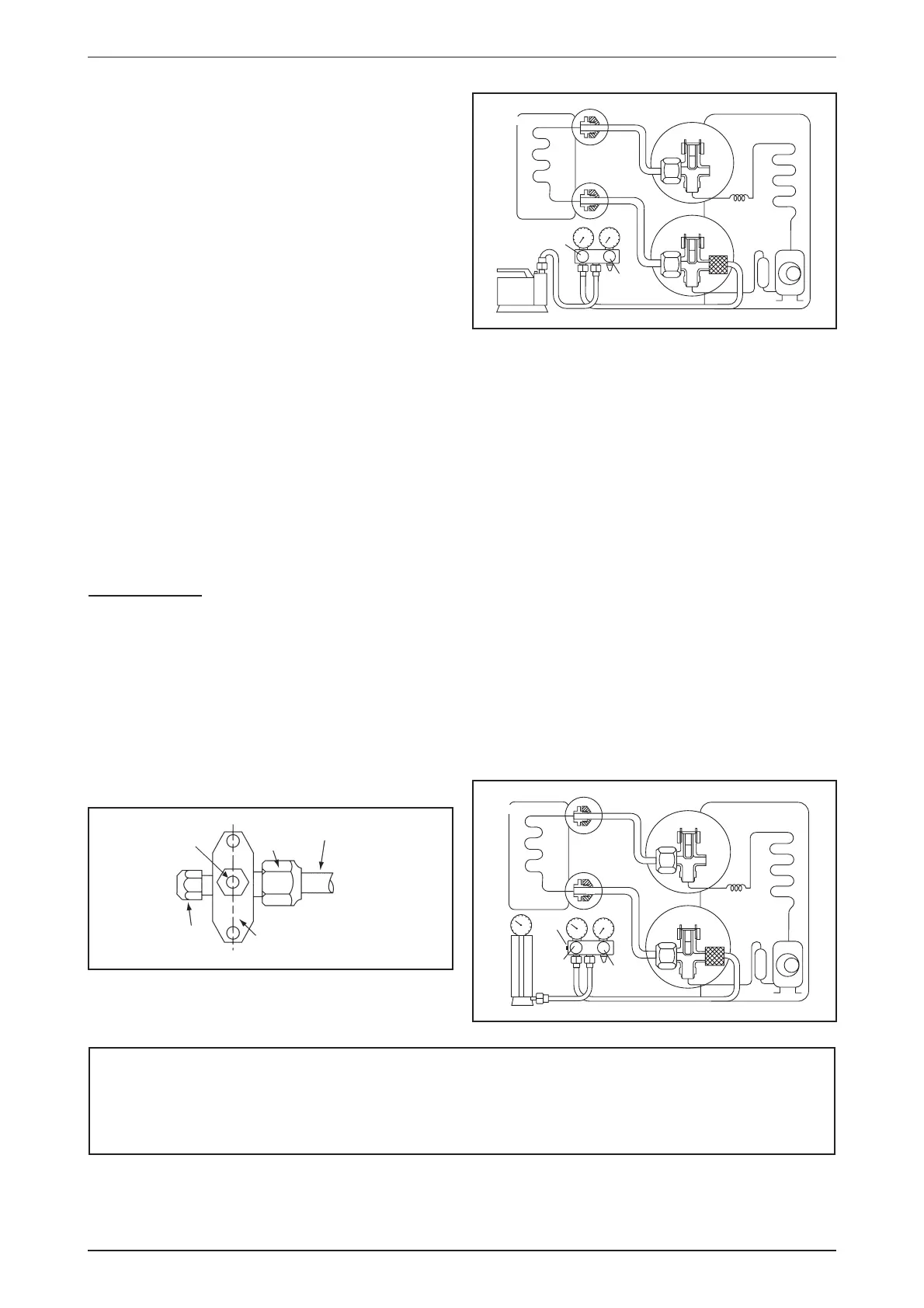

Indoor Unit

Liquid side

Outdoor Unit

Close

Close

Gas side

Close

Open

Vacuum

pump

Discharge valve

Suction valve

Additional charge

The refrigerant is pre-charged in the outdoor unit

for specifi c piping length. Please refer to for further

details on additional charge.

Charge operation

This operation must be done by using a cylinder and

a precise weighing machine. The additional charge is

topped up into the outdoor unit using the suction valve

via the service port.

Remove the service port cap.

Connect the low pressure side of the charging gauge

to the suction service port center of the cylinder

tank and close the high pressure side of the gauge.

Purge the air from the service hose.

Start the air conditioner unit.

Open the cylinder and low pressure charging

valve.

When the required refrigerant quantity is pumped

into the unit, close the low pressure side and the

cylinder valve.

Disconnect the service hose from service port. Put

back the service port cap.

•

•

•

•

•

•

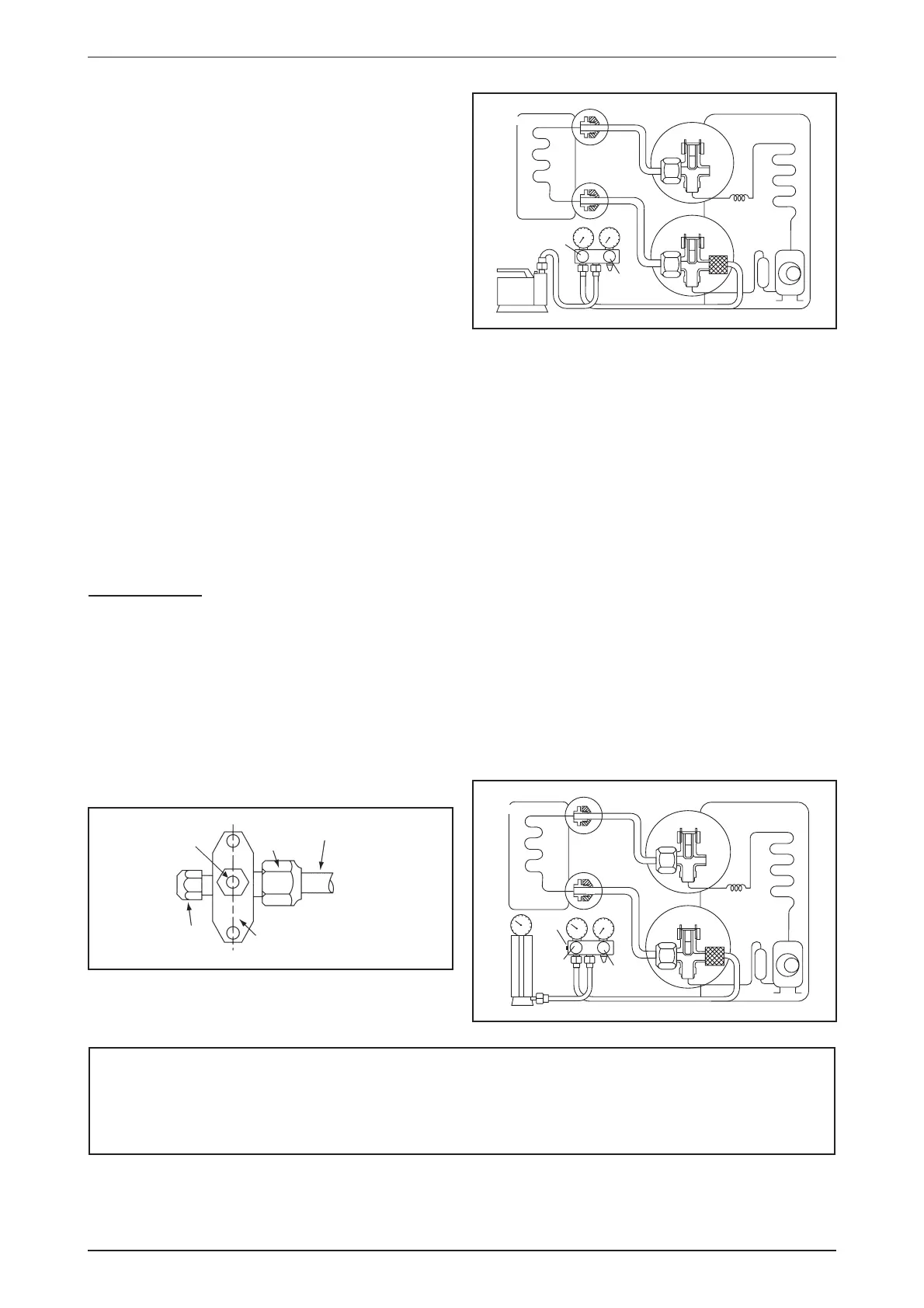

HiLow

Indoor Unit

Liquid side

Outdoor Unit

Open

Open

Gas side

Close

Check

valve

Discharge valve

Suction valve

Open

CAUTION

R410A must be charged as liquid. Usually R410A cylinder is equipped with a dip-pipe for liquid withdrawal.

If there is no dip-pipe, the cylinder should be inverted so as to withdraw liquid R410A from the valve.

Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit thoroughly

and then charge the unit with fresh R410A according to the amount recommended in the specifi cation.

•

•

0

Loading...

Loading...