IM709 5

Disassembly of Sections

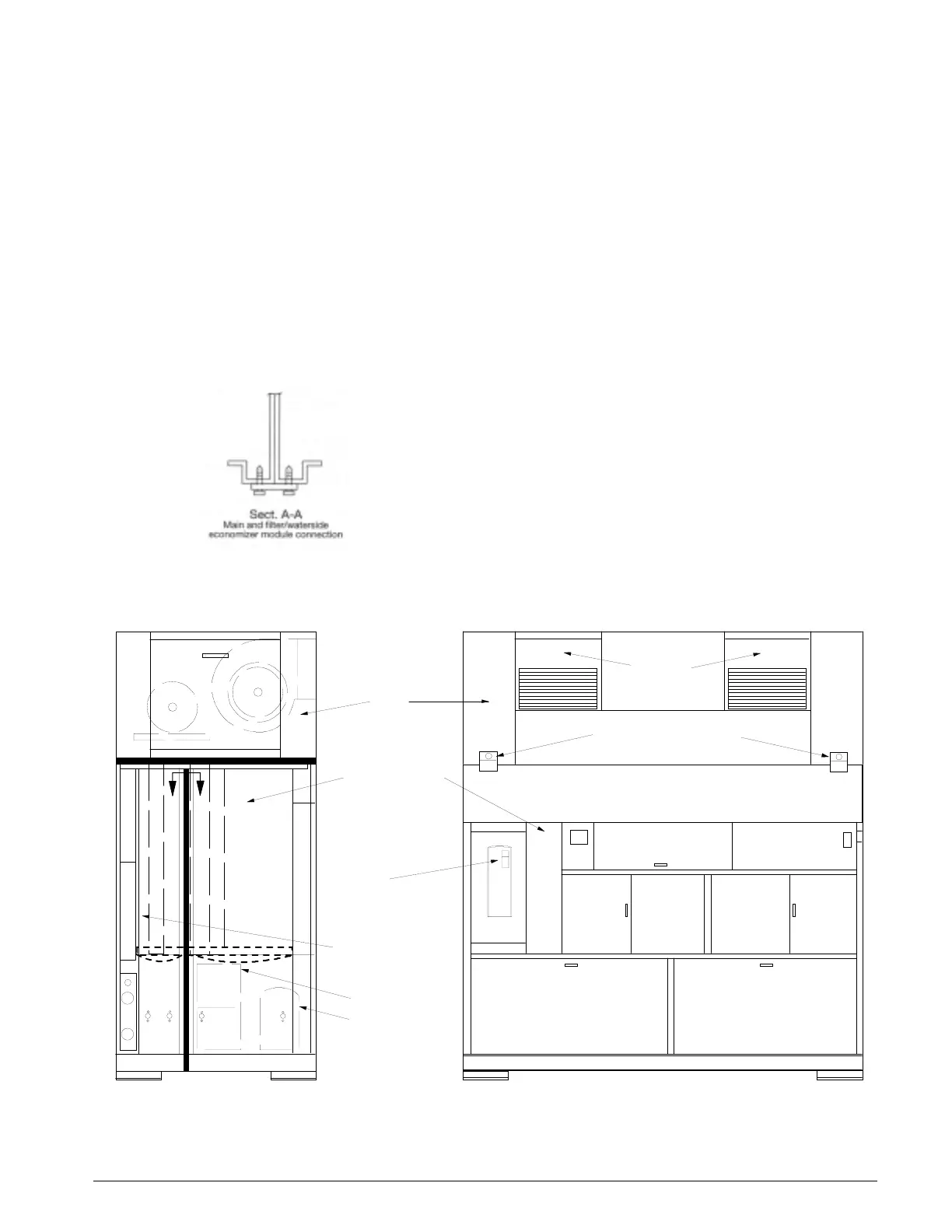

If units are ordered for modular construction, they may be

easily disassembled into three sections. The figures below

illustrate the main cooling/heating, filter/waterside econo-

mizer, and fan sections. The thick lines in the figures show

where the sections are disassembled. The section are secured

by connection plates and screws. The following information

describes the location of the connecting points.

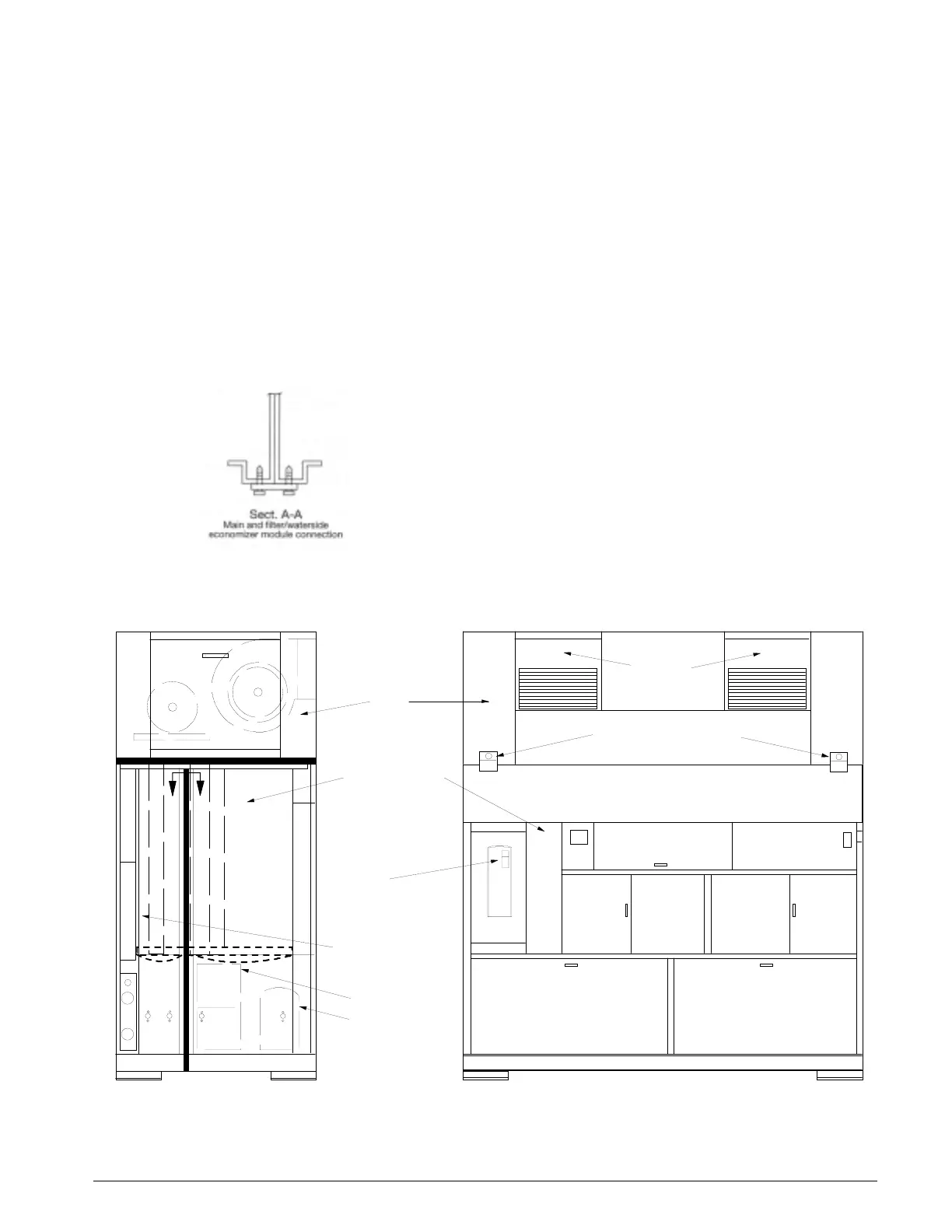

Fan section — base sections disassembly

The fan section sits on the base sections and is secured with

four steel plates. Each plate has two screws in the base sec-

tions and two screws in the fan section. Two of the plates are

shown in Figure 3. The connection plates are also the rigging

plates for the fan section only. They must not be used for rig-

ging the entire unit.

Main cooling/heating — filter/waterside economizer

sections disassembly

The following information is for units ordered for modular

construction (code 32=1). Note: The disassembly of units

not ordered for modular construction (code 32=Y) will

require field modification. Units not ordered for modular

construction do not have victaulic couplings on the water

pipes and the various control sensors are mounted in the unit.

●

Two steel plates the height of the sections connect the

main cooling/heating and the filter/waterside econo-

mizer sections. The plates are secured with multiple

screws on the right and left side of the base sections.

The connection plate and screws are illustrated in Sect

A-A.

●

The filter/waterside economizer section overlaps the

main cooling/heating sections along the bottom and top

adjoining rails. Multiple screws connect the two sec-

tions along these bottom and top overlaps.

●

Victaulic couplings connect the water pipes between the

filter/waterside and main cooling/heating sections. Each

victaulic coupling is secured with two bolts

●

.The condensate drain pipe between the two sections is

connected by a flexible PVC tube with pipe clamps.

Fan

Outlets

FILTER SECTION

EVAPORATOR

HEATER

ELECTRICAL PANEL

ECONOMIZER

AA

Fan

Section

Main Cooling/

Heating Section

Filter/Waterside

Economizer

Section

Condenser

Compressor

Connection Plates

(2)

Figure 2

Figure 3

(1) Unit sizes 018, 023 and 028 have a single fan.

(2) Connection Plates are also the Rigging Plates for the Fan Section only.

ASD

(Optional)

Loading...

Loading...