The provided document is a Service Manual for the MP-60 Infusion Pump manufactured by MEDCAPTAIN. This manual is intended for qualified service personnel and details the device's functionality, operational aspects, and comprehensive maintenance procedures.

Function Description

The MP-60 Infusion Pump is a medical device designed for the controlled delivery of fluids, medications, or nutrients into a patient's circulatory system. Its primary function is to ensure precise and accurate infusion rates, which is critical for patient safety and therapeutic efficacy in various clinical settings. The pump is capable of delivering fluids continuously over a set period, allowing healthcare professionals to manage patient hydration, administer drugs, and provide nutritional support with high reliability.

The device incorporates advanced software and hardware components to manage the infusion process. It features a user interface (UI) that allows for easy programming of infusion parameters such as flow rate, volume to be infused (VTBI), and total volume. The pump is equipped with various sensors and safety mechanisms to monitor the infusion process and detect potential issues. These include sensors for occlusion, air-in-line, and door open conditions, which trigger alarms to alert clinicians to critical events. This multi-layered safety system helps prevent over-infusion, under-infusion, and other complications that could harm the patient.

The MP-60 is designed to be versatile, accommodating different types of infusion sets and clinical protocols. Its ability to maintain a consistent and accurate flow rate is paramount, especially for medications that require strict dosage control. The pump's internal architecture supports both driver software, which manages the core mechanical and electronic functions, and UI software, which provides the interactive interface for users. This separation allows for robust operation and flexible updates.

Usage Features

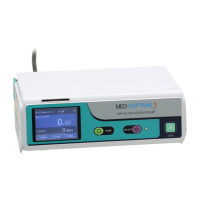

The MP-60 Infusion Pump is designed with user-friendliness and safety as key priorities for healthcare professionals. Its appearance suggests a portable and robust design, suitable for various clinical environments, including hospitals, clinics, and potentially home care settings. The device features a clear display, likely an LCD or similar screen, that presents critical infusion information such as current flow rate, infused volume, and alarm status. This visual feedback is essential for clinicians to quickly assess the pump's operation.

The user interface includes intuitive controls, such as buttons for power on/off, start/stop, and navigation through menus. The presence of a "HOME" button suggests quick access to the main operational screen, simplifying workflow. The "CN-OFF" button likely refers to a power control, indicating ease of operation. The pump's design emphasizes ease of setup and programming, allowing medical staff to quickly initiate infusions.

Safety features are integrated throughout the device's operation. The pump is equipped with an alarm system that provides both visual and audible alerts for various conditions, including:

- Occlusion: Detection of a blockage in the infusion line, preventing fluid flow.

- Air-in-line: Detection of air bubbles in the infusion line, which can be dangerous if infused into the patient.

- Door open: Indication that the pump's door or mechanism for securing the infusion set is not properly closed.

- Battery low: Warning when the internal battery charge is insufficient, prompting connection to AC power.

- System errors: General device malfunctions that require attention.

These alarms are crucial for ensuring patient safety by prompting immediate intervention from healthcare providers. The pump's ability to operate on both AC power and an internal battery provides flexibility, allowing for continuous operation even during power outages or patient transport. The battery operation feature enhances mobility, making the pump suitable for use in ambulances or during inter-departmental transfers within a hospital.

The device's design likely includes features for easy loading and unloading of infusion sets, minimizing the risk of errors during setup. The overall operational philosophy is to provide a reliable, safe, and easy-to-use tool for administering intravenous fluids.

Maintenance Features

The Service Manual outlines comprehensive maintenance procedures for the MP-60 Infusion Pump, emphasizing the importance of regular checks and qualified personnel. Maintenance is critical to ensure the device's continued safety, reliability, and performance.

Personnel Qualifications: Only personnel with specific qualifications are permitted to perform service and maintenance. These qualifications include:

- Basic knowledge of electronic circuits and mechanical systems.

- Basic knowledge of medical devices and clinical applications.

- Proper training in maintenance service from MEDCAPTAIN.

- Knowledge of the device's principle, structure, performance, and operation.

- Access to necessary equipment and instruments.

- Permission from MEDCAPTAIN.

General Maintenance Principles:

- Electrostatic Discharge (ESD) Protection: Maintenance must be conducted under ESD-protected conditions. Service personnel are explicitly warned not to touch PCBAs or semiconductors without protective measures to prevent damage from static electricity.

- Display Protection: Sharp objects should not be used on the display to avoid damage.

- Sterilization Methods: The pump should not be disinfected using high-pressure steam sterilization.

- Battery Management: Before internal battery operation, the battery charge should be checked, and recharged if necessary, to ensure sufficient power.

- Liquid Intrusion Prevention: Connecting parts (AC power socket, USB, nurse call socket) must be dry before connecting cables to prevent short-circuits.

Key Maintenance Activities:

- Cleaning and Sterilizing: Regular cleaning and sterilization procedures are essential to maintain hygiene and prevent cross-contamination.

- Periodic Maintenance: This involves routine inspections and checks to identify potential issues before they lead to device failure. This likely includes checking mechanical components, electrical connections, and sensor functionality.

- Replacing the Battery: Instructions are provided for replacing the internal battery, a common wear-and-tear component.

- Software Upgrade: The manual details procedures for upgrading both the driver software and the UI software. This ensures the pump benefits from the latest features, bug fixes, and performance enhancements. The process involves specific steps for downloading and installing software updates, highlighting the device's upgradability and long-term support.

- Alarm, Fault, and Troubleshooting: A dedicated section provides information on various alarms and faults, along with detailed troubleshooting steps. This guides service personnel in diagnosing and resolving issues efficiently, minimizing downtime.

- Device Fault Checking and Troubleshooting: This section likely includes flowcharts or step-by-step guides for identifying the root cause of specific malfunctions.

- Device Maintenance: This covers general repair and adjustment procedures.

- Disassembling and Installing: Detailed instructions for disassembling and reassembling the pump are provided. This is crucial for accessing internal components for repair or replacement. Attentions are given to specific steps and tools required.

- Cleaning After Maintenance: Post-maintenance cleaning ensures the device is ready for clinical use.

- Safety Tests: After any maintenance or repair, specific safety tests are required to confirm the device meets electrical safety standards. These include:

- Electric Leakage Test of Enclosure: Checks for current leakage from the device's casing.

- Electric Leakage Test of Ground: Verifies the integrity of the protective earth connection.

- Electric Leakage Test of Patient: Measures leakage currents that could potentially flow through a patient connected to the device.

- Maintenance Spare Parts List: A list of spare parts is included to facilitate ordering and replacement of components.

MEDCAPTAIN emphasizes that all disassembly, replacement, testing, modification, and repair must be conducted by qualified personnel using only MEDCAPTAIN-provided replacement parts, accessories, and consumables. This ensures the integrity and safety of the device are maintained. Furthermore, maintenance records must be kept for each product, indicating a commitment to traceability and quality control. The manual also states that MEDCAPTAIN reserves the right to modify the contents for more accurate and effective service quality, with updates reflected in newly published versions.