10 Chapter III Dex CM3000

Full-Digital Control CO

2

/MAG/MIG Multi-FunctionWelding Machine

2. Turn the knob on the right panel to adjust F13 parameters (shown in table 3-6).

3. Shortpress “Function” key to exit from internal menu and F13 parameter settings is completed.

Table3- 6Parameter Table of Transition Time of Wire Feeding Speed

Function Code Unit Adjusting Range Step Length Default Value

F13 s

0.01~9.99S

0.01s 0.1s

Post-gas Time (F14)

Post-gas time after arc ending.

1. Enter into internalmenu by holding on “Function” key 3 seconds; turn the panel knob to F14.

2. Adjust the F14parameters, press“Function” again, F14 parameter settings is completed.

Table3-7Parameter Table of post-gas Time

Function Code Unit Adjusting Range Step Length Default Value

F14 s

0~25s

0.1s 1s

Wire InchingSpeed (F15)

The speed in which the wire is sent to the tip of the torch under the non-welding condition.

1. Enter into internal menu; turn the panel knob to F15. Press “Function” key, then the right LCD will be

twinkled.

2. Adjust F15 parameters by rotating the right knob (Table 3-8).

3. Press “Function”key againto exit from internal menu, F15 parameter settings is completed.

Table3-8 Parameter Table ofManual Wire Feeding Speed

Function Code Unit Adjusting Range Step Length Default Value

F15 m/min.

1.4~8 m/min.

0.1 m/min.

Automatic

Matching

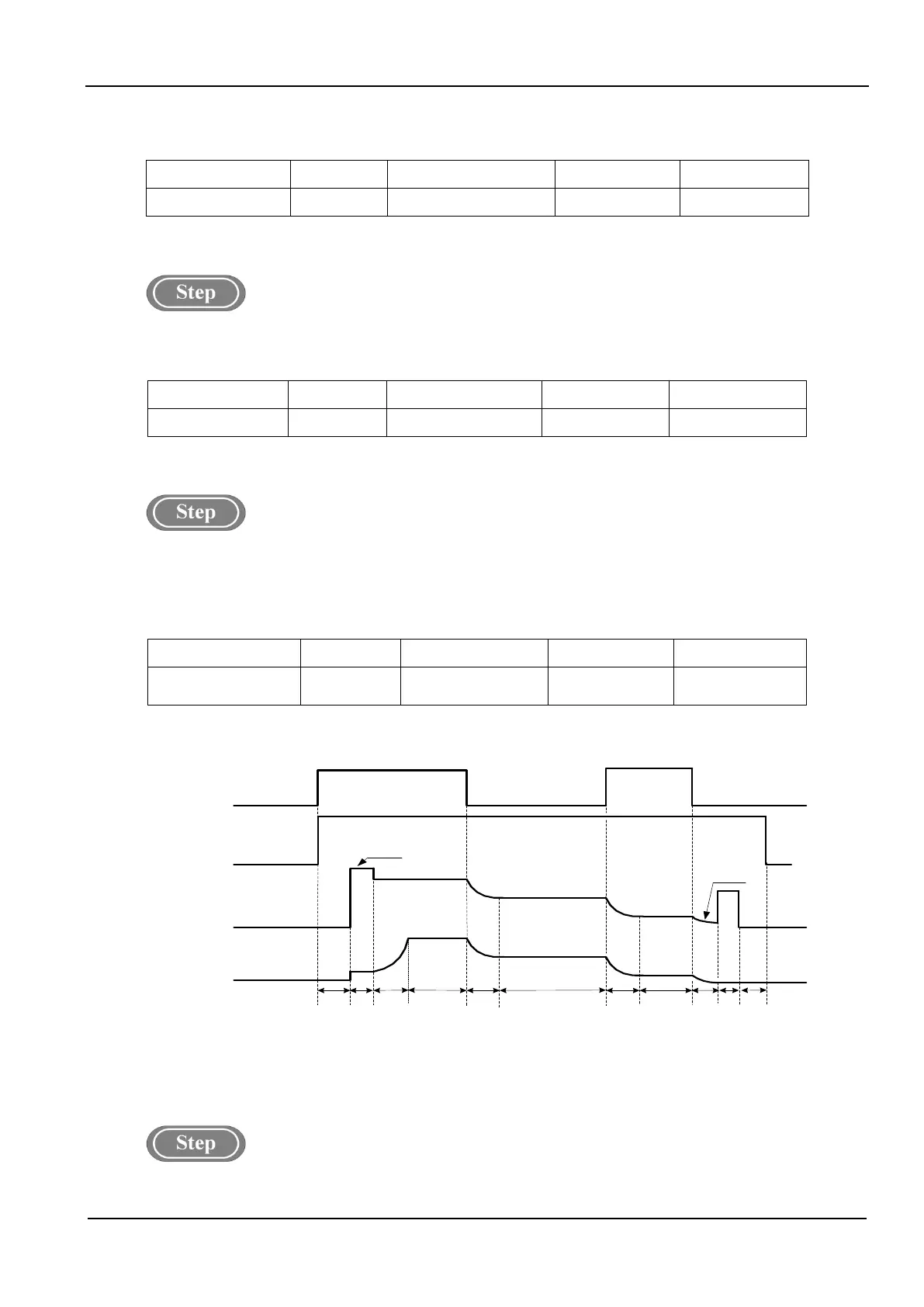

Logicdiagram of DC parameters.

As shown in the figure3-4.

Welding Torch

Switch

Gas Delivery

Welding

Voltage

Wire Feeding

Speed

(Welding Current)

Preflow

Gas

No-Load

Voltage

Arcing

Process

Welding Process

DC

Burn-

Back

Time

OFF

ON

OFF

ON

OFF

Arc-

Retreating

Process

Soft-

Start

Time

Transition

Time of Wire

Feeding Speed

Slow

Wire

feeding

DC

Chopping

Time

Burn-Back

Voltage

Transition

Time of Wire

Feeding Speed

Lagging Gas

Delivery

Fig.3-4Logic Diagram of DC Parameters(2T)

DC Burn-Back Voltage(F20)

1. Enter into internal menu by long pressing “Function” key; turn the panel knob to F20.

Loading...

Loading...