18 Chapter IV Dex PM3000

Full-Digital Control CO

2

/MAG/MIG Multi-FunctionWelding Machine

4.2 Wire Inching

Wire is sent to tip of welding torch by manual under non-welding condition.

1. Press on "Wire Inching" key, the LED light will be on.

2. The wire inching speed is rated wire feeding speed. The maximumwire inching speed is 8 meters/min.

Release the function button; LED light is off, then wire feeding stops.

4.3 Gas Detection

Check whether there is gas or not, and gas flow rate.

1. Touch “Gas Detection” button, LED light will be on.

Gas starts to flow. Then gas flow rate can be checked. Gas detection function will be shut down

automatically 30 second later.

2. Press the button again,light LED will be off and gas detection stopped.

4.4 Synergic /Separation

Synergic:The system will automaticallymatch corresponding voltage based on the set-up giving

welding current and synergic voltage corrected value. Standard synergic voltage corrected value is 0.

Voltage modification range is ±30.

The rated voltage relationship is as below:

The rated welding voltage= synergic voltage+(voltage modification value%)×(synergic voltage)

1. Pressing " Synergic/separation" button, then enter intosynergic mode after LED light turns on.

2. Switch the “RightRotating Switch” key to synergicvoltage corrected value "±".

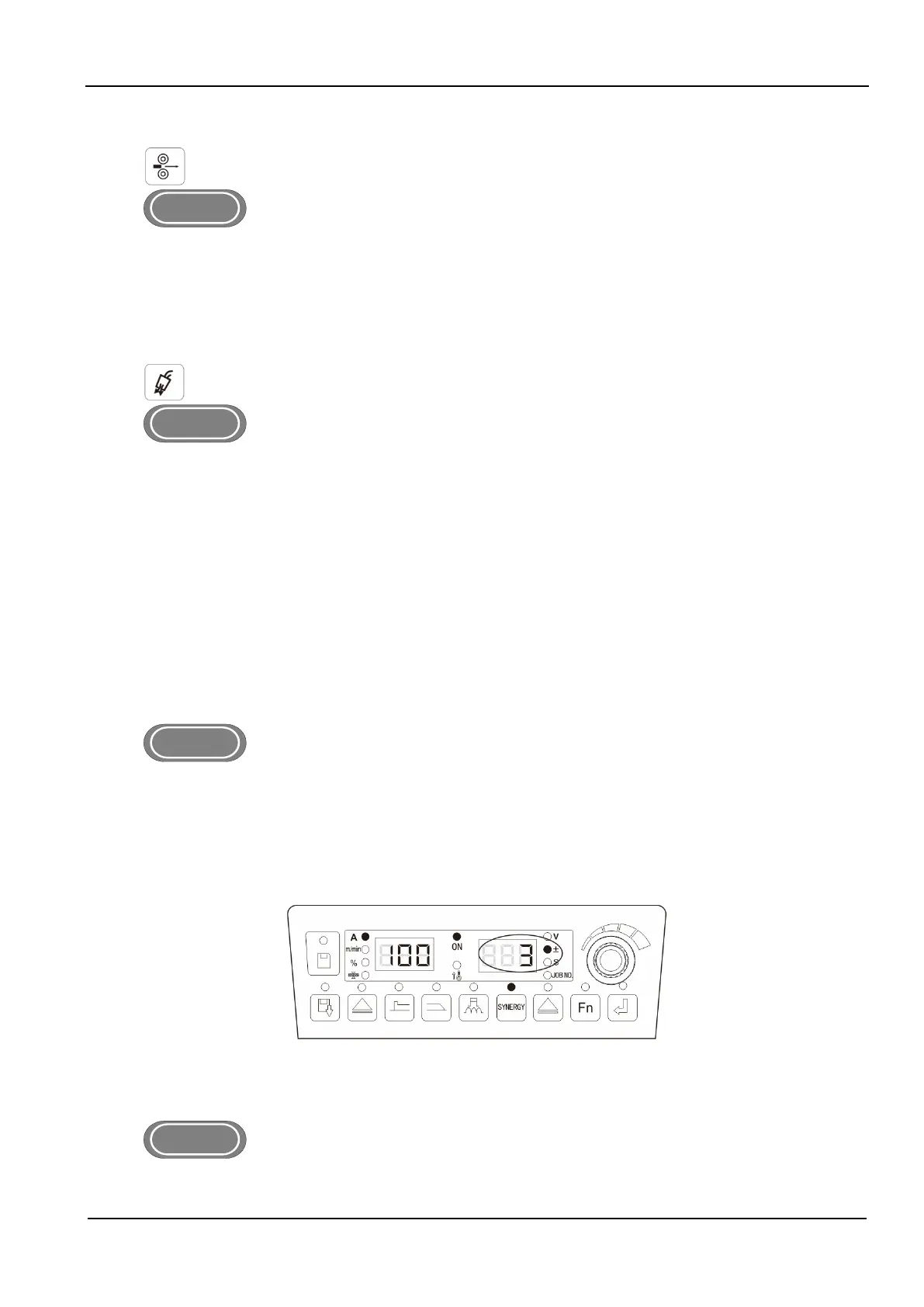

3. When the indicator light is on or flashing, fine tuning the automatically matched violated under

synergic mode by regulating the voltage knob on wire feeder on front panel, as 4-2 figure shows:

4. The matched value for voltage and arc length corrected value can be viewed by switching “Right

Rotating Switch” key.

Fig.4- 2SynergicMode Matching Voltage CorrectedValue Interface

Separation:Current and voltage is adjusted separately.

Long-pressing "Function" key more than 3 seconds. Then enter into “Separation” mode when the LED

turns off.

Loading...

Loading...