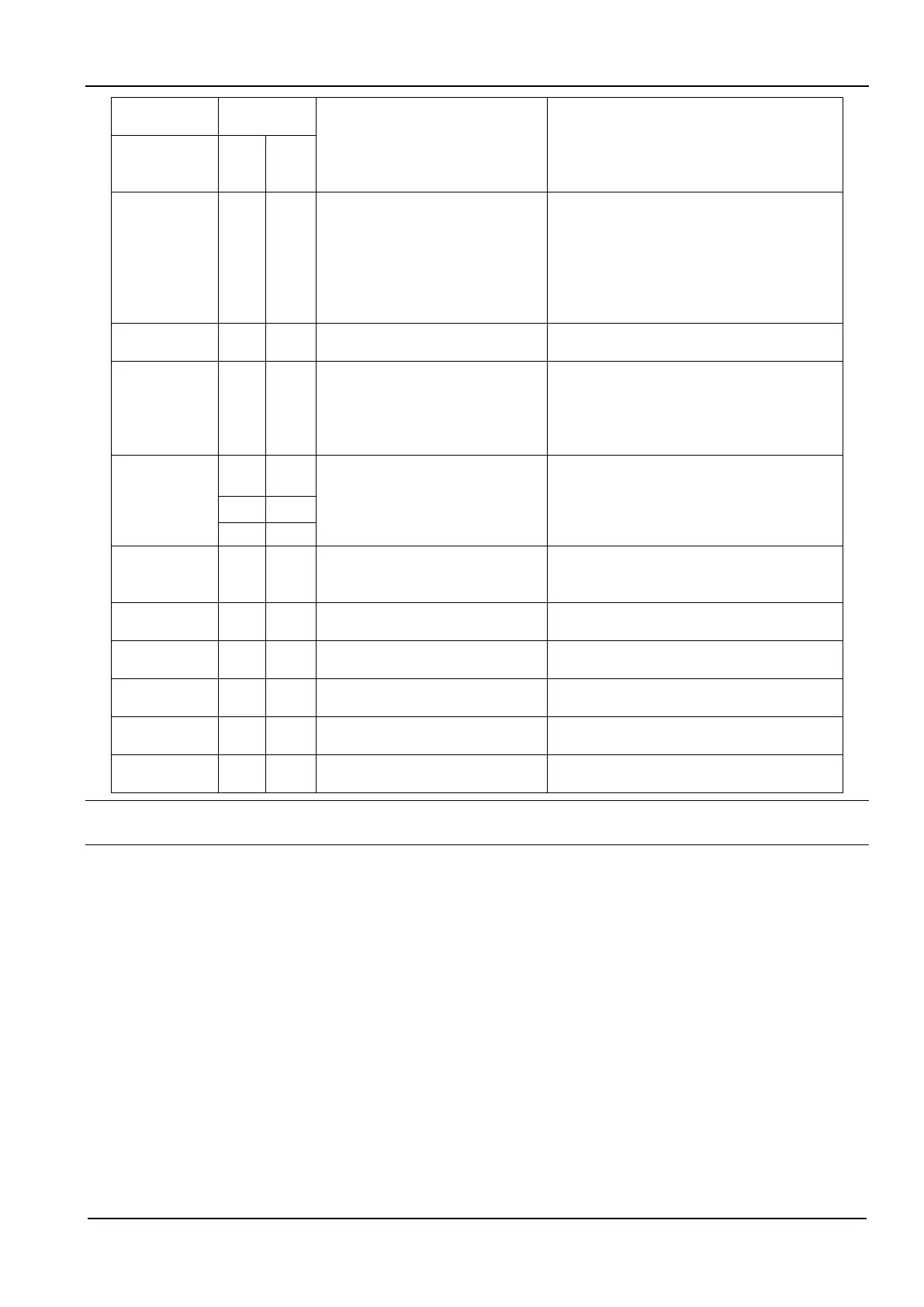

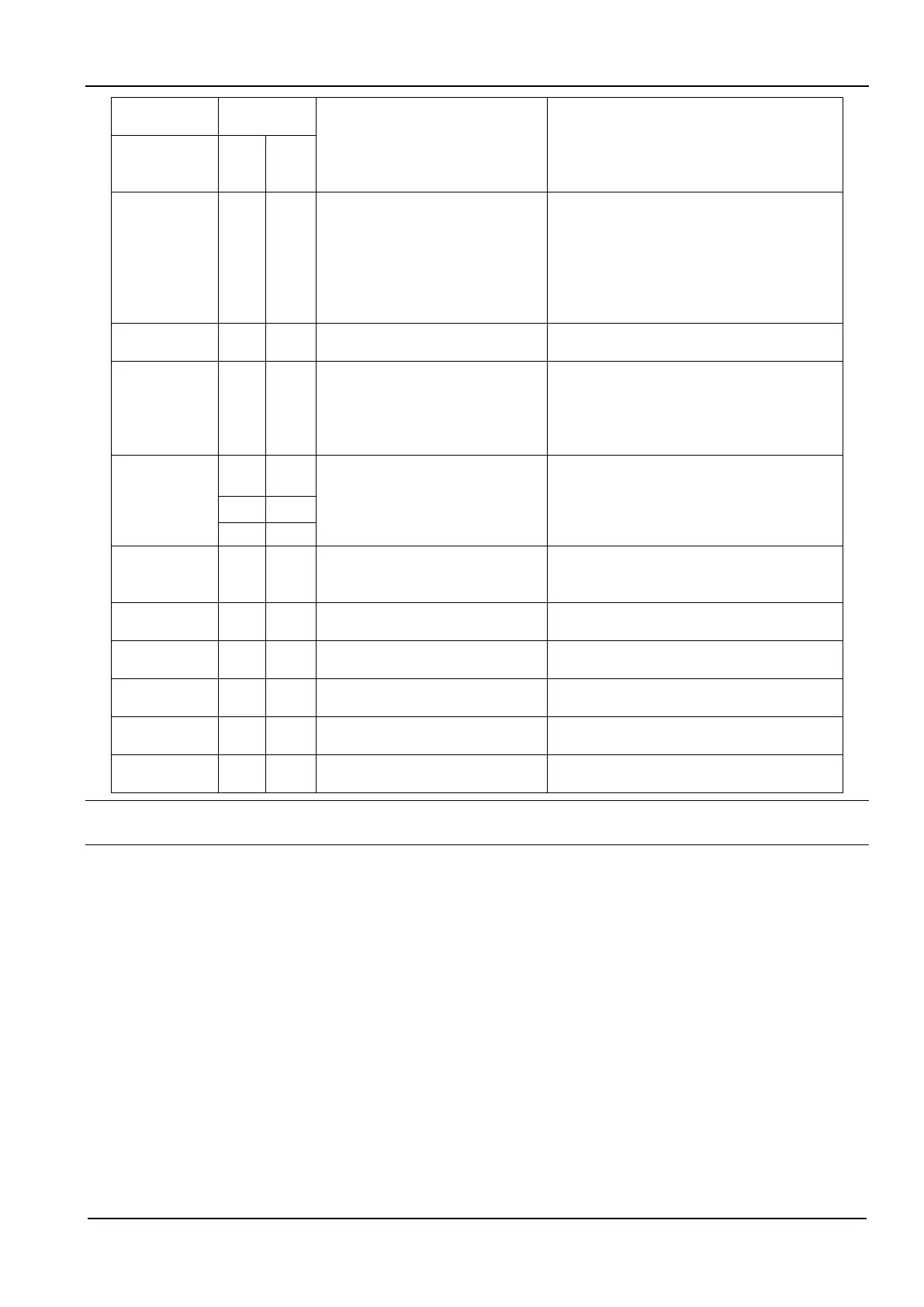

34 Chapter V Troubleshooting

Full-Digital Control CO

2

/MAG/MIG Multi-FunctionWelding Machine

Fault Type

Fault Code

Fault Description and Reason Solutions

Left

Nixie

Right

Nixie

Overcurrent is too high.

2. Output diode module is damaged.

nozzles and the contact tip is inadhesion, and if

the welding wire is stick to work-piece and occur

close short).

2. After inspection, press the welding torch , can

go back to work.

3. Check whether the output diode module is

Communication

E7 1 Internal communication failure.

Check whether the terminals on the display panel

and main control board are loosed.

Output

Overvoltage

E8

The output voltage is too high.

Main transformerdamage.

Wrong output connection.

1. Check if there are other machines connecting

voltage to the output terminals.

2. Check whether the main transformer is

damaged.

3. Check the output connection.

PrimarySide

Over-Current

E9 11

Main transformer damage.

Output diode module damage.

Main power board damaged.

1. Check the main transformer;

2. Check the output diode module;

3. Check the main power board; the welder can

be restored after the inspection.

E9 12

E9 2

The Current

Hall is not

Inserted.

E11 Current hall connector is not inserted. Check the current hall connector.

Wire Feeder

E13 Overcurrent of wire feed motor

Check whether the welding wire is blocked or

Fan Failure E15 Short circuit or open circuit of fan.

Check whether the fan is jammed or in short

circuit.

Encoder Failure

(

DexPM3000)

E17

The signal terminals of the code disc

are not firmly connected.

Check whether the signal terminal of the code

disc is firmly connected.

Heating Valve

Failure

E30 Heating Valve Overcurrent

Check whether the heating valve socket is short

circuit.

Motor Power

E33

The power cord of the motor is

Check whether the motor power cord is reversely

Attention

The fault type with the * is only for the model machine in parentheses.

Loading...

Loading...