LEFT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6B-31

Reassembly and Installation of Counter Rotation Gear

Housing

Driveshaft Needle Bearing

REASSEMBLY/INSTALLATION

CAUTION

If driveshaft needle bearing failure has occurred, and original bearing race has

turned in the gear housing, gear housing must be replaced. Loose fitting needle

bearing will move out of position and cause repeated failures.

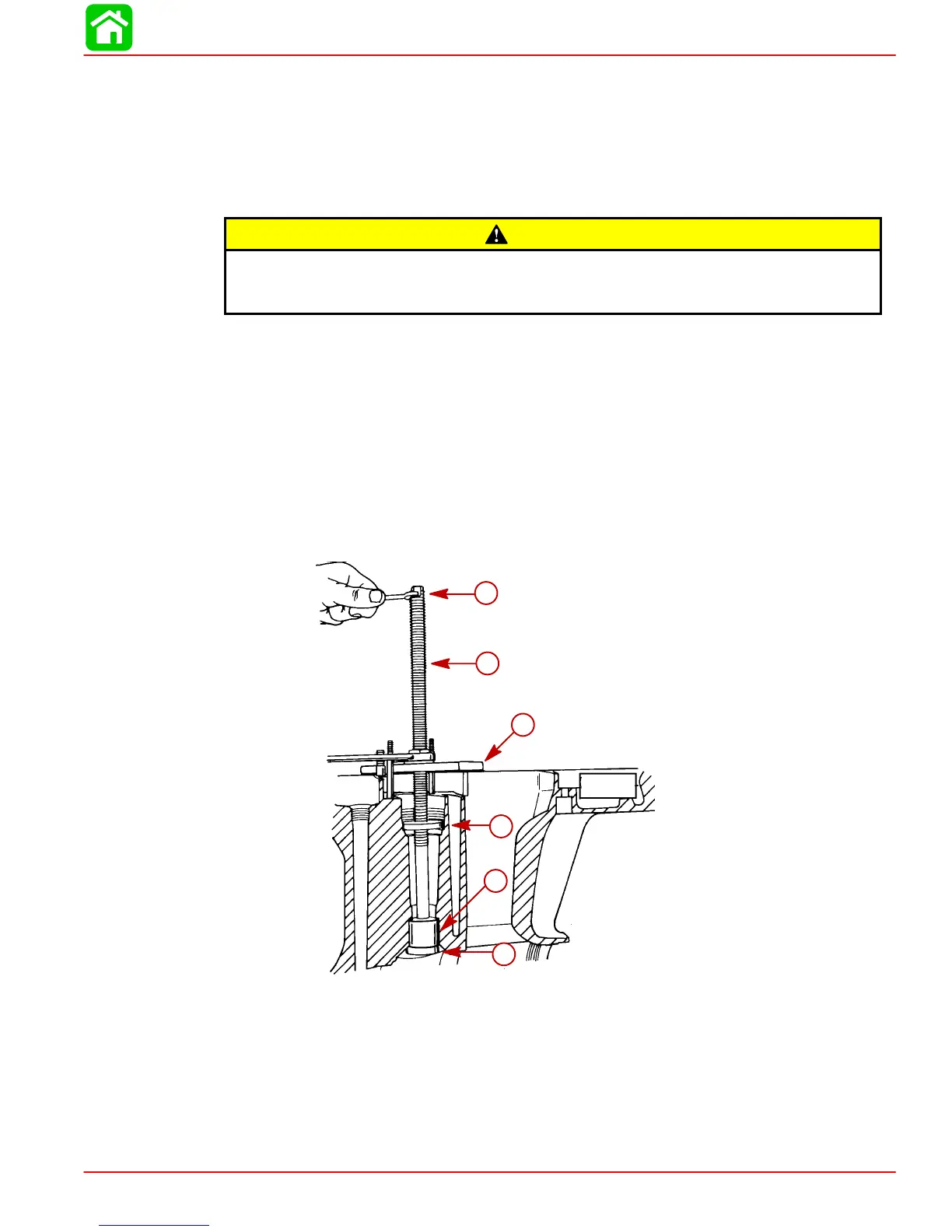

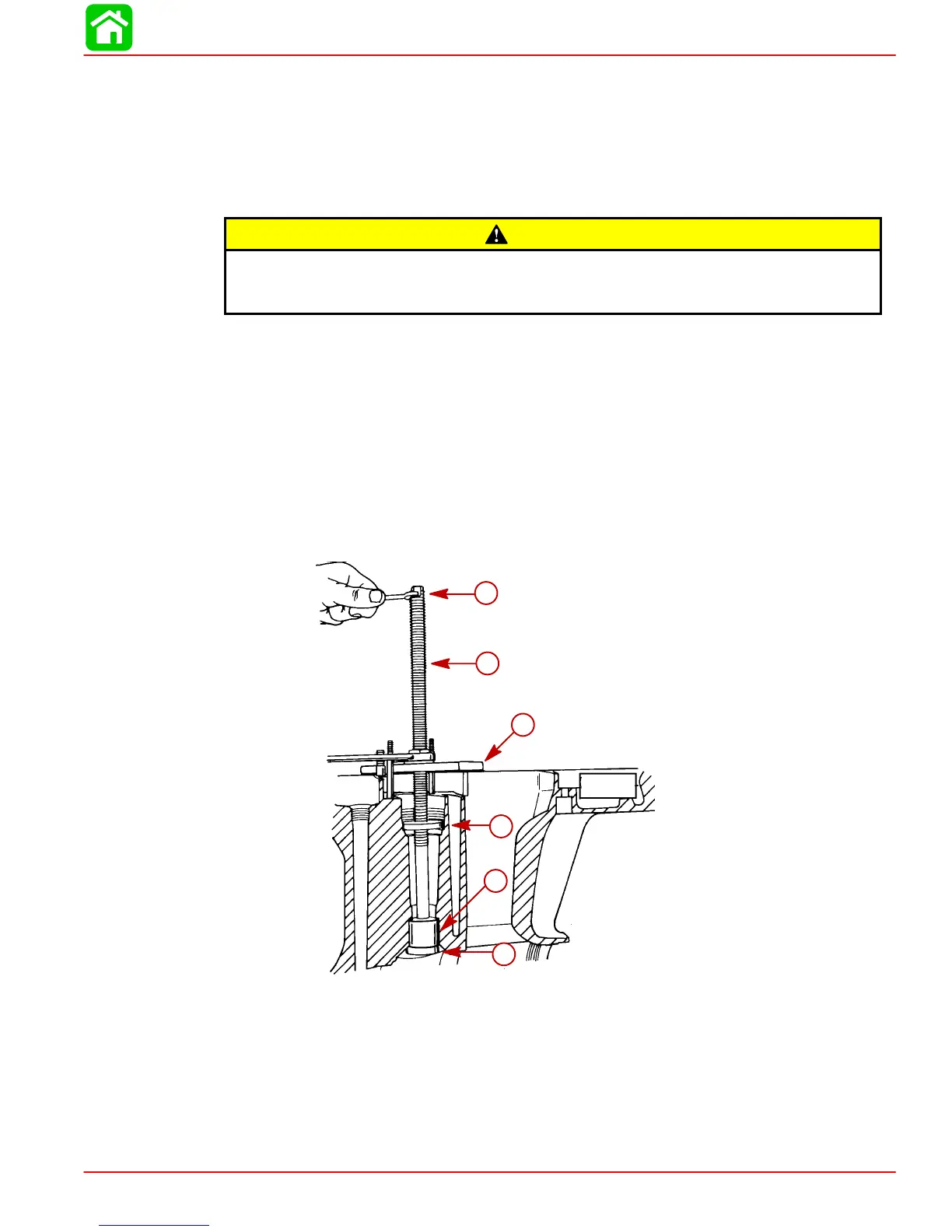

NOTE: Driveshaft needle bearing must be installed prior to installation of reverse gear.

1. Apply a thin coat of Quicksilver 2-4-C w/Teflon Lubricant to driveshaft needle bearing

bore in gear housing.

2. By way of propeller shaft cavity, place needle bearing in driveshaft bore with num-

bered side of bearing facing up driveshaft bore.

3. Install and seat needle bearing with the following tools: Puller Rod* (91-31229), Nut*

(91-24156), Pilot* (91-36571), Plate* (91-29310), and Mandrel* (91-92788). Pull

bearing up into bore until it bottoms on gear housing shoulder. (DO NOT use exces-

sive force.)

*From Bearing Removal and Installation Kit (91-31229A5)

51869

a

b

c

d

e

f

a-Mandrel

b-Bearing

c-Pilot

d-Plate

e-Puller Rod

f-Hold

Loading...

Loading...