LEFT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6B-39

Pinion Gear Depth

DETERMINING PINION GEAR DEPTH

NOTE: Read entire procedure before attempting any change in shim thickness.

IMPORTANT: Reverse gear assembly must be installed in gear housing when

checking pinion gear depth or an inaccurate measurement will be obtained.

1. Clean gear housing bearing carrier shoulder.

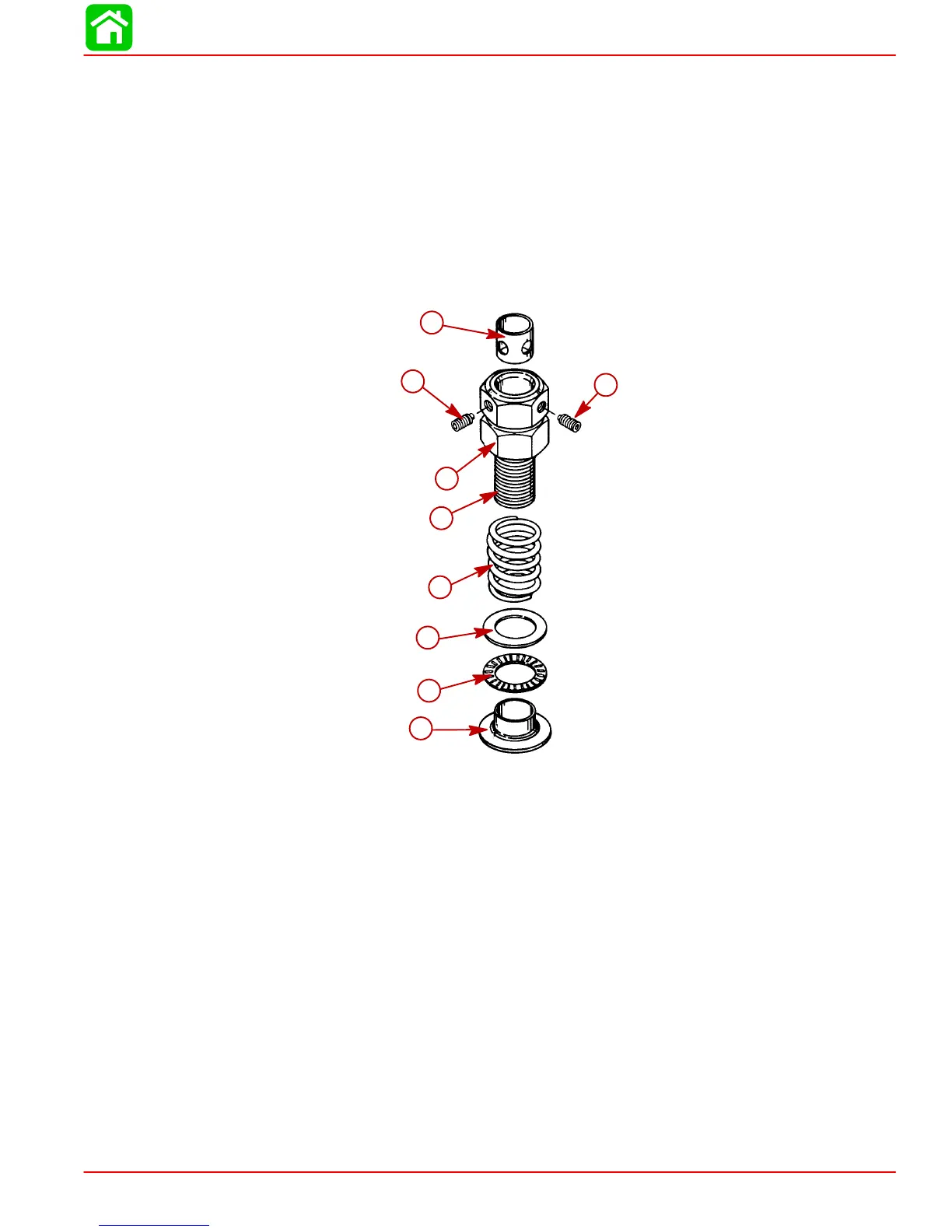

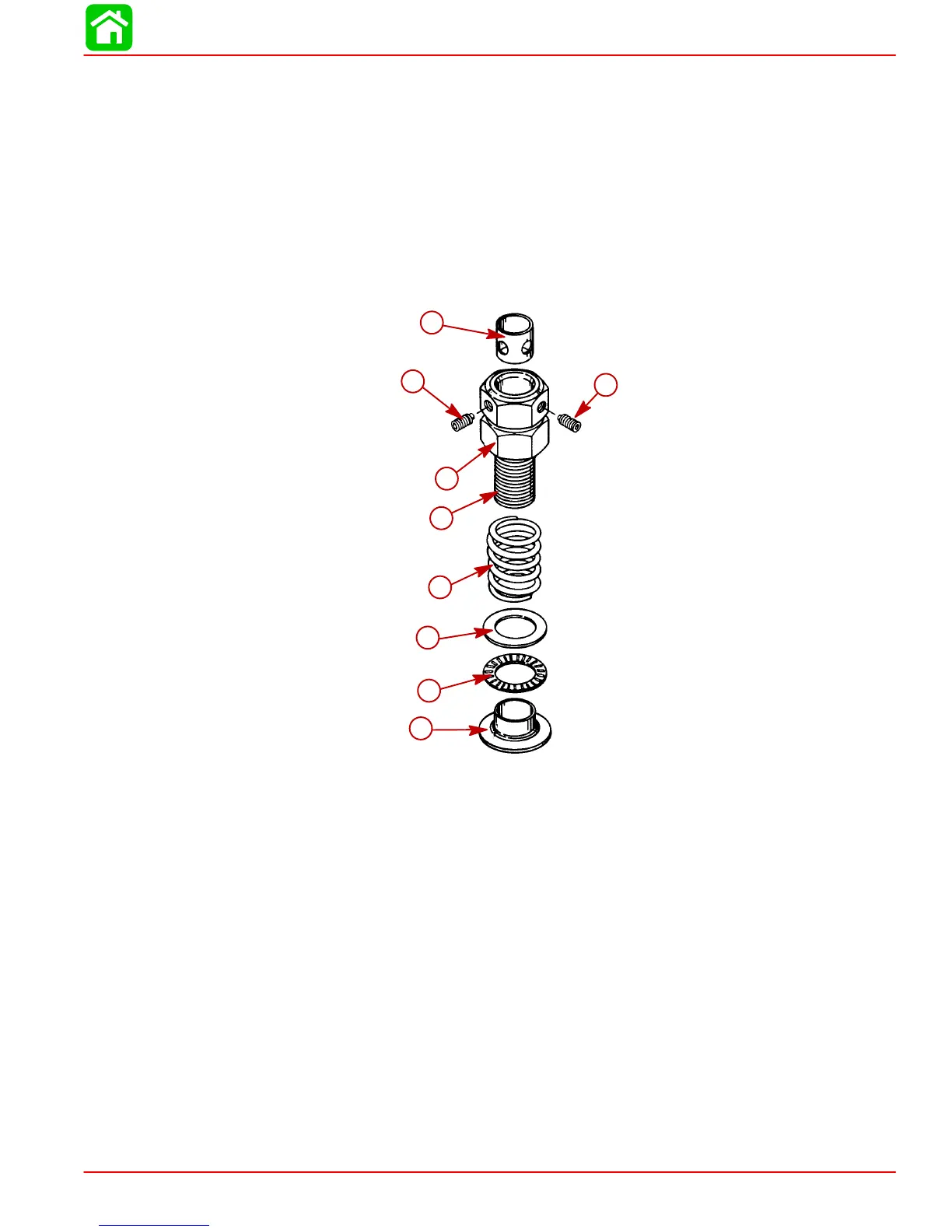

2. Install Bearing Preload Tool (91-14311A1) over driveshaft in sequence shown.

NOTE: Bearing Preload Tool (91-44307A1) may also be used. Follow instructions pro-

vided with tool for proper installation.

a

b

c

d

e

f

g

h

g

a-Adaptor

b-Bearing

c-Washer

d-Spring

e-Nut; thread nut all the way onto bolt

f-Bolt

g-Set Screw

h-Sleeve; holes in sleeve must align with set screws

3. Align adaptor on driveshaft bearing pocket ledge.

4. With tool installed over driveshaft, tighten both set screws securely, making certain

to align sleeve holes to allow set screws to pass thru.

Loading...

Loading...