LEFT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6B-41

NOTE: Bearing Preload Tool (91-14311A1) should remain installed on driveshaft after

setting pinion gear depth as it is required to properly check forward gear and reverse gear

backlash.

Reverse Gear

DETERMINING REVERSE GEAR BACKLASH

NOTE: Reverse gear backlash is adjustable using shims; it can be checked as follows:

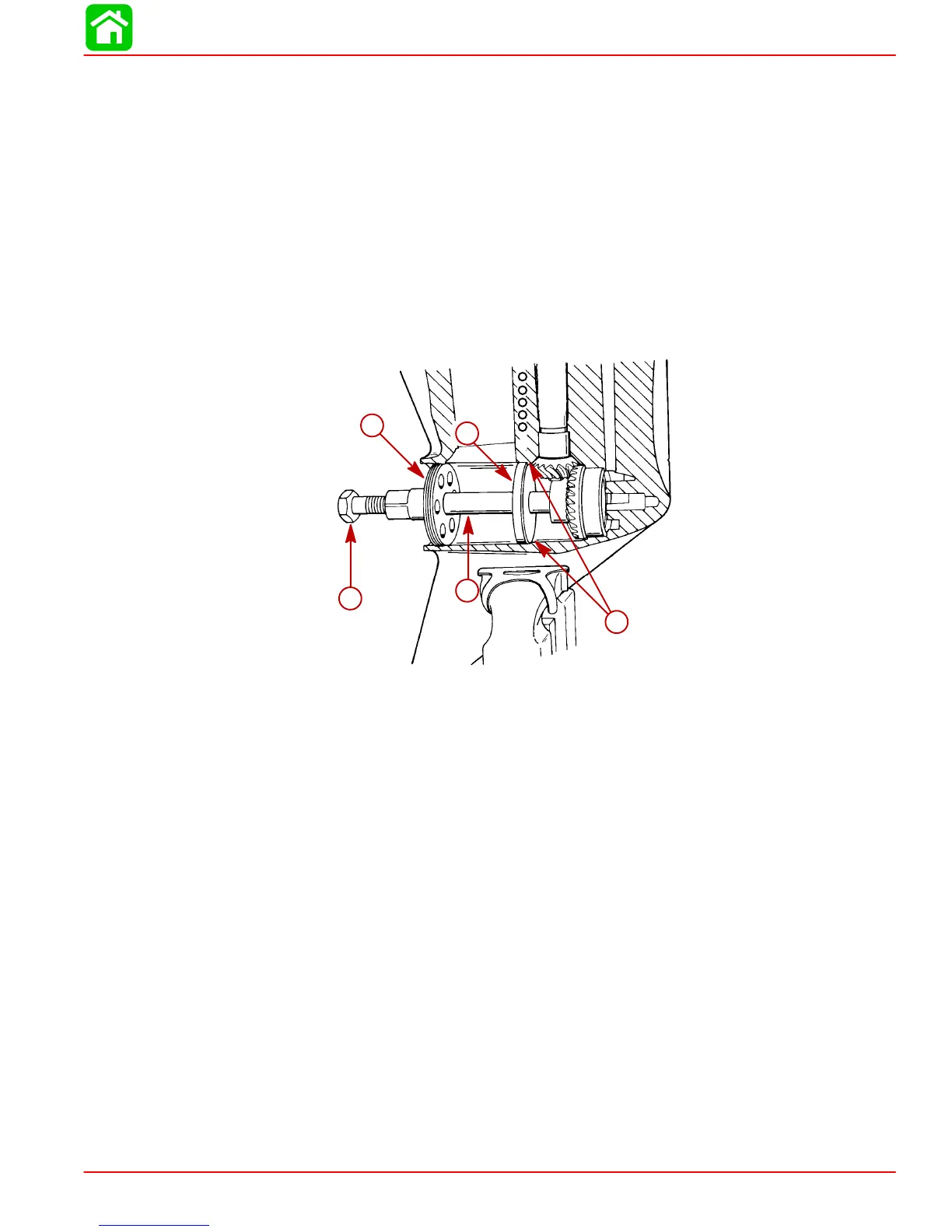

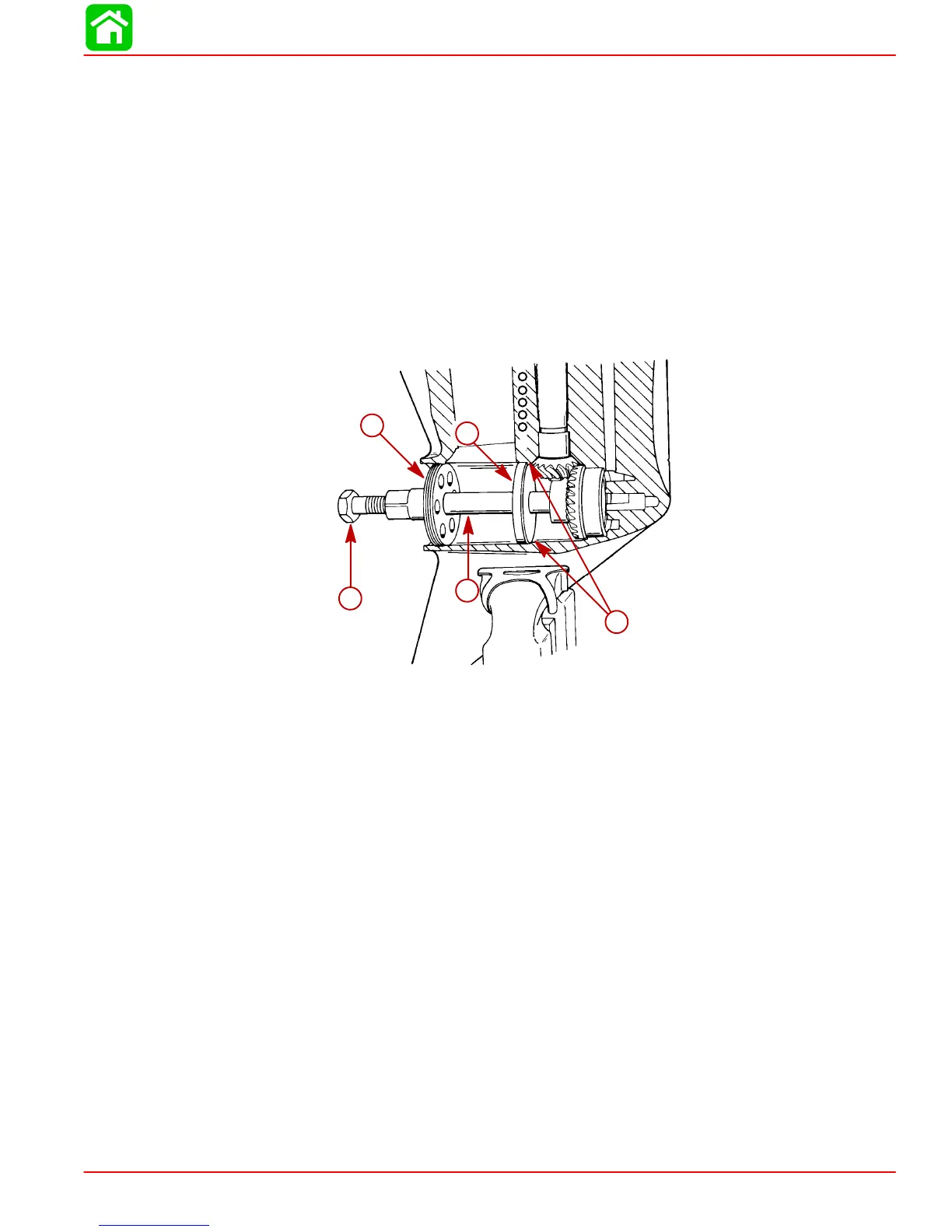

1. Install Driver Tool (91-18605) into reverse gear assembly.

2. Slide Pilot Ring (91-18603) over driver tool and seat pilot ring against inner ledge in

gear case.

3. Thread Retainer (91-18604) into gear case cover nut threads.

4. Torque Screw (91-18602) to 45 Ib. in. (5 Nm) against driver tool.

51884

a

b

c

d

e

a-Driver Tool (91-18605)

b-Pilot Ring (91-18603)

c-Inner Ledge

d-Retainer (91-18604)

e-Screw (91-18602) [Torque to 45 lb. in. (5 Nm)]

5. Thread stud adapter [from Bearing Preload Tool (91-14311A1)] all the way onto stud.

6. Install: Backlash Indicator Tool (91-78473)

Dial Indicator Holder (91-89897)

Dial Indicator (91-58222A1)

7. Position dial indicator pointer on line marked “1” on Backlash Indicator Tool, if gear

ratio is 1.87:1 (15 teeth on pinion gear), or on line marked “2” on Backlash Indicator

Tool, if gear ratio is 2:1 (14 teeth on pinion gear).

8. Lightly turn driveshaft back-and-forth (no movement should occur at propeller shaft).

Loading...

Loading...