SECTION 4 - COUNTERSHAFT, CTRSHAFT BOX & SHEAVE ASSEMBLIES

4-6

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

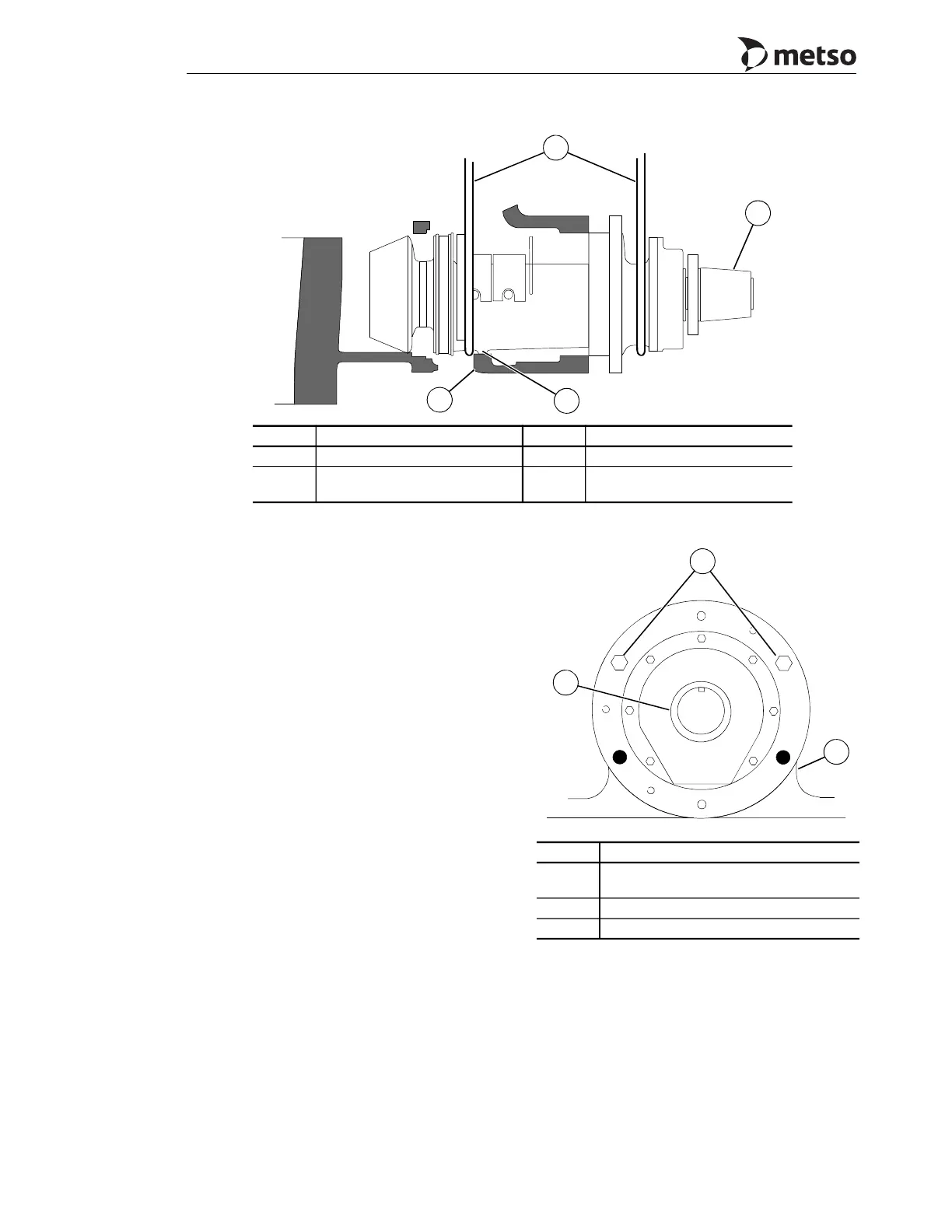

Figure 4-5 Installing Countershaft Box Assembly

7. Lower the pinion end of the countershaft

box, again making sure the countershaft box

centering lug rests on the main frame guide

support.

8. Insert two M42 x 220 LG, for the MP1000,

or M36 x 220 LG for the MP800 hex head

pull-in capscrews into the tapped holes in

the main frame at the position shown in

Figure 4-6. These pull-in capscrews are part

of the tools that came with the Crusher.

9. Alternately tighten each pull-in capscrew a

small amount, to prevent binding, until there

is a 50 mm (2.0") gap between box flange

and main frame as shown in View 2 of

Figure 4-7.

10. Remove the two pull-in capscrews and place

spacers or a stack of washers, 50 mm (2.0")

thick onto the capscrews. Reinstall them into

the frame. Again alternately tighten each

bolt until a 20 mm (0.75") space between the

countershaft box flange and main frame is

obtained as shown in Views 3 and 4,

Figure 4-7.

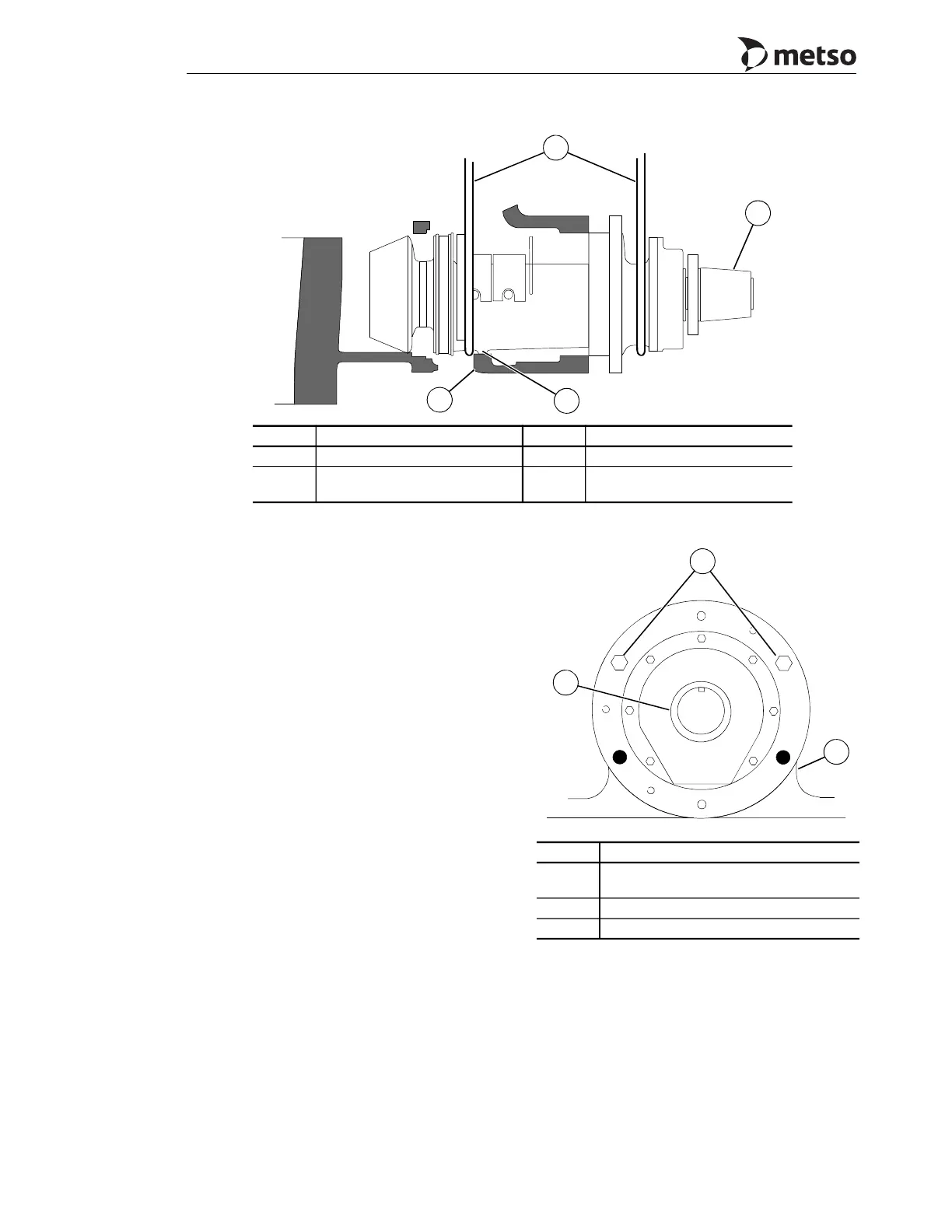

Figure 4-6 Countershaft Box Pull-In Capscrew

Placement

Callout Description Callout Description

1 Lifting slings 3 Countershaft box centering lug

2

Sheave bushing (or set collar,

direct drive)

4 Frame support guide

1

2

4

3

Callout Description

1

Place countershaft box pull-in capscrews

in locations shown

2 Countershaft box flange

3 Oil flinger housing

1

2

3

Loading...

Loading...