Do you have a question about the Metso MP800 and is the answer not in the manual?

Safety guidelines for operating within a crushing plant environment.

Provides fundamental safety rules for safe operation of the crusher.

Covers essential safety procedures and precautions for maintenance and repair tasks.

Details lockout procedures and general safety practices for maintenance activities.

Focuses on safety measures for mechanical aspects during maintenance operations.

Guidance on preventing and managing fire hazards during maintenance work.

Safety protocols for performing electrical work during maintenance and repair.

Safety precautions and procedures for working with hydraulic systems.

Methods and procedures for proper V-belt tensioning to ensure optimal performance.

Describes using the percent elongation method for V-belt tensioning.

Details the process of installing the crusher onto its foundation or structure.

Maintenance procedures for the main frame and related assemblies.

Procedure for replacing a faulty accumulator unit in the system.

Steps for installing the countershaft box assembly into the main frame.

Maintenance procedures for countershaft, box, and sheave assemblies.

Procedure for replacing worn or damaged pinions on the countershaft.

Guide for reassembling the countershaft box after maintenance or repairs.

Methods for checking and adjusting gear backlash and root clearance for optimal meshing.

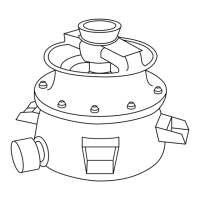

| Brand | Metso |

|---|---|

| Model | MP800 |

| Category | Industrial Equipment |

| Language | English |