Slurry Pump

WH18AM12AA0EN_01F.DOC JAN 04-W08

Care and maintenance

1/2

9.5.2 Hydraulic parts and frame - dismantling and fitting

(ii) Wet-end - disassembly and reassembly

1. General

Case (W1), impeller (W3) and back-liner (W4) are high quality, high-chrome iron castings.

Larger size pump cases are ribbed and incorporate a number of lifting lugs. The inlet and

outlet branches are fitted with joint seals (F2, F4) and split flanges (F1, F3) to provide a

leak-proof and secure pipework connection.

The back-liner, which forms the rear face of the case, is attached to bearing frame (P14)

by tee bolts (W19) and hexagon-headed nuts (W20). For ease of assembly, the bolts are

retained in the slots by means of a rubber strap (W18). O-rings (W6) are used to seal the

back liner and the case.

The wide choice of impellers available permit the most efficient case-impeller combination

to be adopted for each application.

2. Removing impeller (W3) and back-liner (W4)

a) If an impeller release mechanism is fitted refer to section 9.5.2 (iii); otherwise,

insert a suitable bar between two impeller vanes and lock the bar against a

suitable static object. Apply a shock load by turning shaft (B11) in a direction

opposite to the pump rotation. Alternatively, lock the shaft and shock the

impeller. Sub-section 2.1.2 identifies the direction of rotation of the pump during

operation.

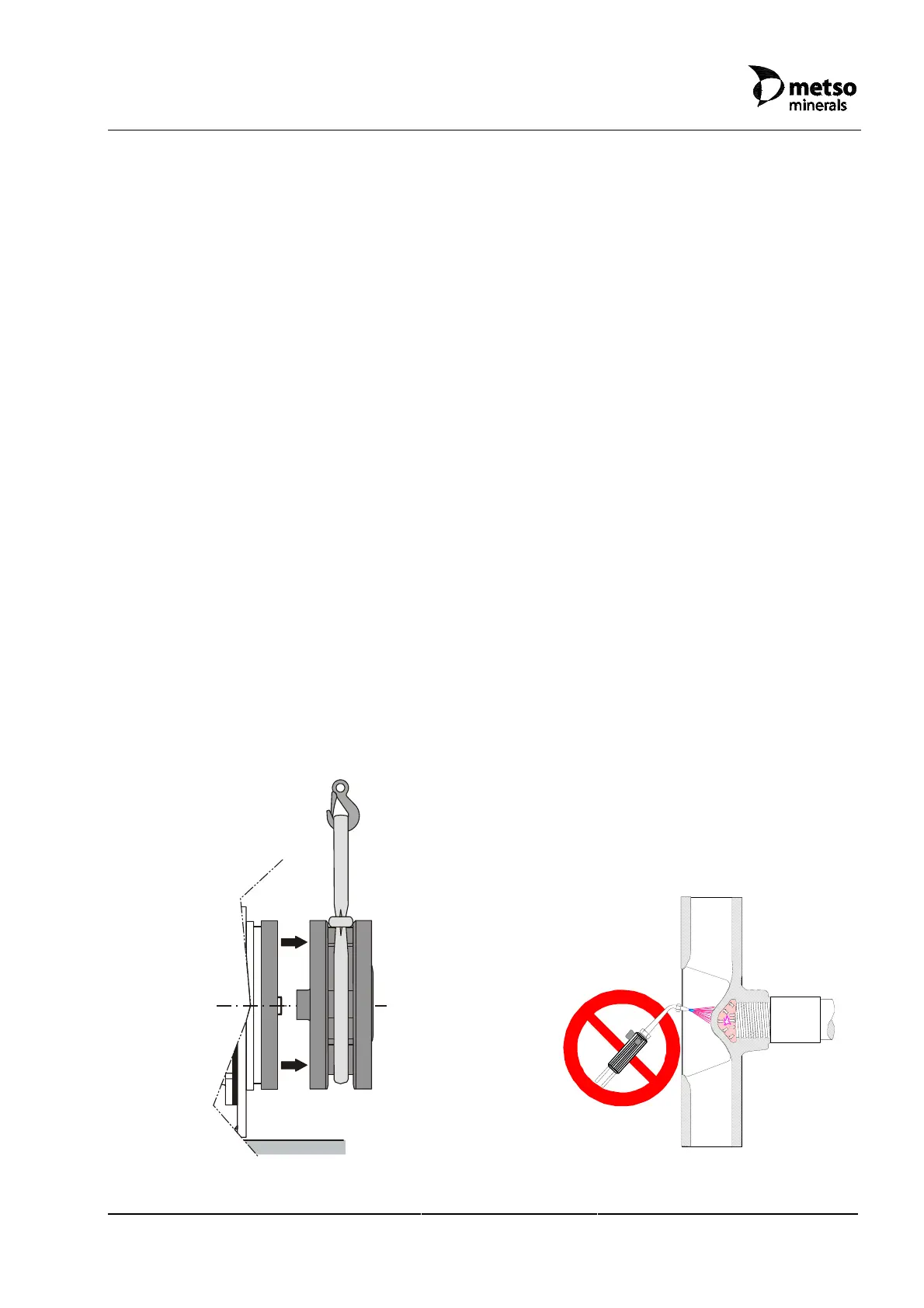

b) Steady and suitably support impeller (W3) as it moves off shaft (B11).

Figure 9.5.2-A Removing impeller (W3)

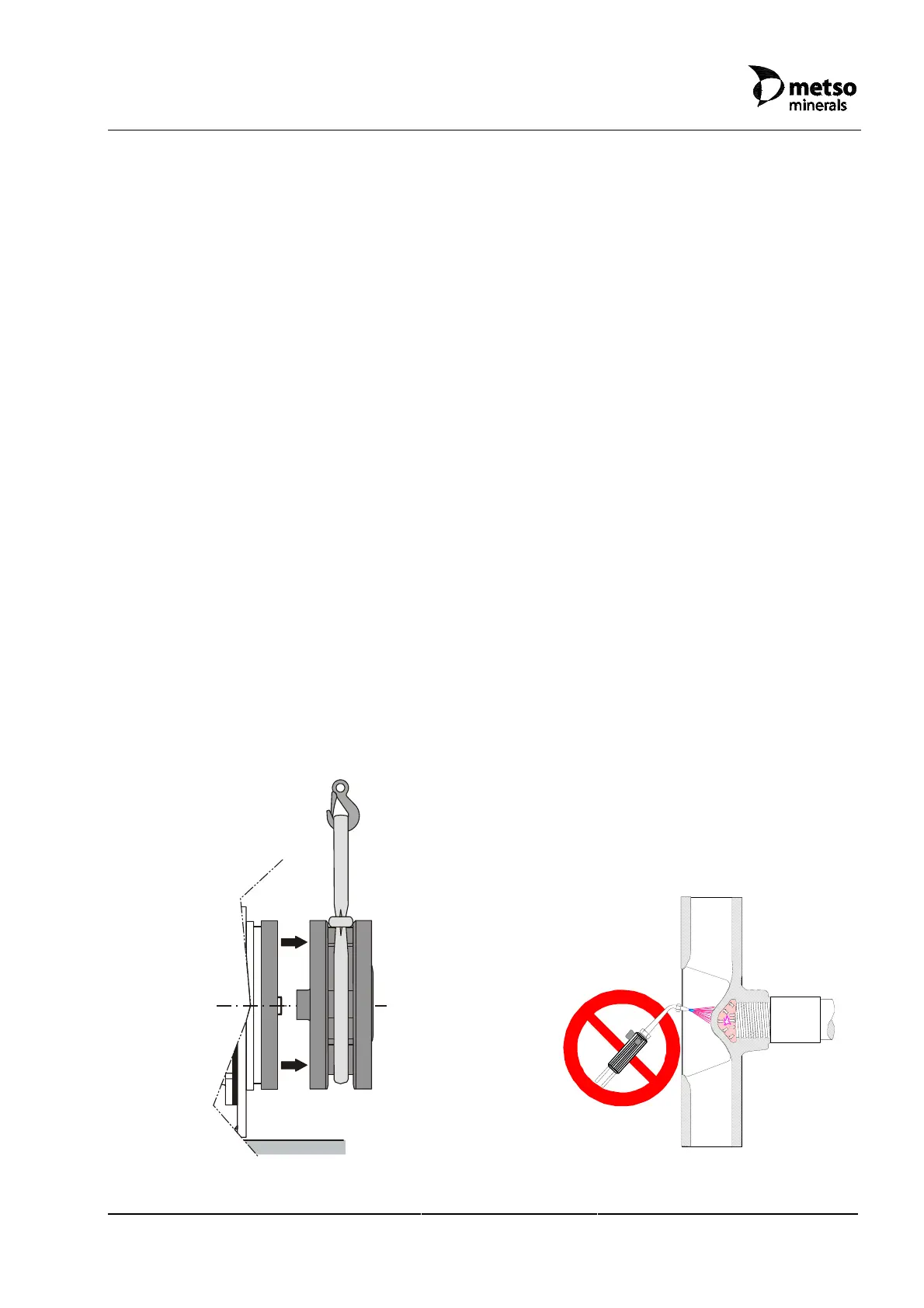

DANGER OF

EXPLOSION

DO NOT

APPLY

HEAT

Figure 9.5.2-B Do not apply heat in order

to remove the impeller

Loading...

Loading...