HEATING

AND

VENTILATING

RUNNING

INSTRUCTIONS

HEATER

The heating

and

ventilating system is designed to pro vide fresh air either heated

by the engine cooling system or at outside temperature to the car at floor level

and for demisting and defrosting to the windscreen.

Air

Two doo rs, located one at each side of the gearbox tunnel, control distribution

distribution

of air between screen

and

car interior. To supply air to the car, open the

doors;

to boost the flow of air to the screen, close the doors.

Choice

of

fuel

Always use fuel with an octane rating best suited to your engine (see

'GENERAL

DATA').

Our

1972 Austin

and

MG engines ha ve not been designed to operate on lead-free

or clear gasolines and use of such fuels

cannot

be recommended as they could

have a detrimental effect on engine components, resulting in loss of perform-

ance, excess exhaust emissions and , possibly, complete engine failure.

Controls

Heater

(Fig ..1). A valve controlling the flow of coolant through the heater

unit

is fitted at the rear of the cylinder head. The valve is opened by turning it in

an

anti-clockwise direction when heating is required or shut off by turningclockwise

when the system is to be used for cool air ventilation.

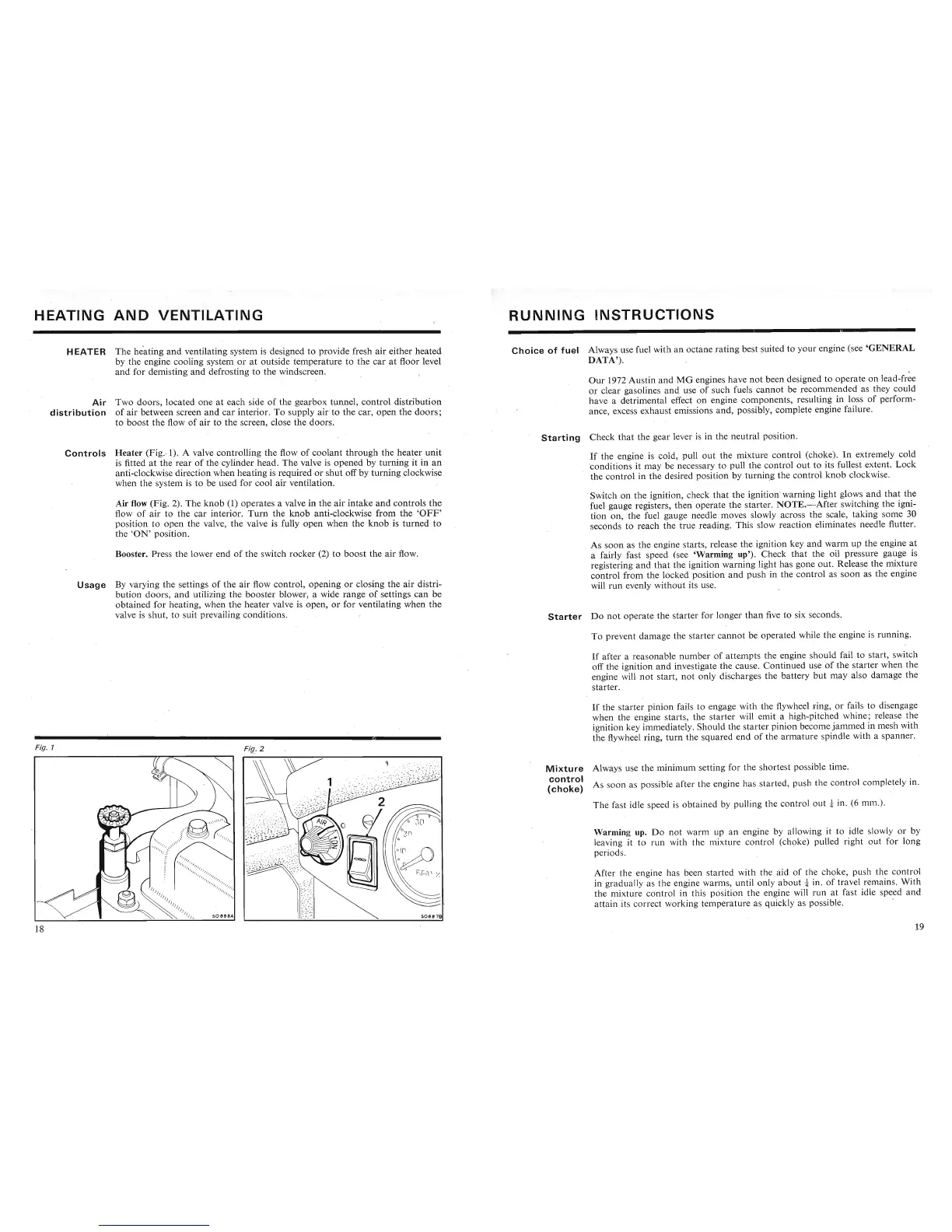

Air flow (Fig. 2). The knob (1) operates a valve in the air intake

and

controls the

flow of air to the car interior.

Turn

the

knob

anti-clockwise from the

'OFF'

position to open the valve, the valve is fully open when the

knob

is turned to

the 'ON' position.

Booster. Press the lower end of the switch rocker (2) to boost the air flow.

Usage

By varying the settings of the air flow control, opening or closing the air distri-

bution doo rs,

and

utilizing the booster blower, a wide range of settings can be

obtained for heating, when the heater valve is open, or for ventilating when the

valve is shut, to suit prevailing conditions.

Starting

Check

that

the gear lever is in the neutral position.

If

the engine is cold , pull out the mixture control (choke). In extremely cold

'conditions it may be necessary to pull the control

out

to its fullest extent. Lock

the control in the desired position by turning the control

knob

clockwise.

Switch on the ignition, check

that

the ignition'warning light glows and

that

the

fuel gauge registers, then operate the starter.

NOTE.-After

switching the igni-

tion on, the fuel gauge needle moves slowly across the scale, taking some 30

seconds to reach the true reading. This slow reaction eliminates needle flutter.

As

soon

as the engine starts, release the ignition key and

warm

up the engine at

a fairly fast speed (see 'Warming up'). Check

that

the oil pressure gauge is

registering

and

that

the ignition warning light has gone out. Release the mixture

control from the locked position

and

push in the control as

soon

as the engine

will

run

evenly without its use.

Starter

Do not operate the starter for longer

than

five to six seconds.

To prevent damage the starter

cannot

be operated while the engine is running.

If after a reasonable number of attempts the engine should fail to start, switch

off the ignition

and

investigate the cause. Continued use of the starter when the

engine will

not

start, not only discharges the battery

but

may also damage the

starter.

The fast idle speed is obtained by pulling the control out

tin

. (6 mm.) .

Mixture

Always use the minimum setting for the shortest possible time.

control

I I I .

As soon as possible after the engine has started, push the contro comp ete y m.

(choke)

ance, excess exhaust emission s and, possibly , complete engine failure .

If the starter pinion fails to engage with the flywheel ring, or fails to disengage

when the engine starts, the starter will emit a high-pitched whine; release the

ignition key immediately. Should the starter pinion become

jammed

in mesh with

the flywheel ring,

turn

the squared end of the armature spindle with a spanner.

Fi!l....2

2

__

___

.c-:x

~

"

~~

"

_u ' A/I! _ (L _,

r;;/

~

distribution

of air between screen

and

car interior. To supply air to the car, open the

doors;

to boost the flow of air to the screen, close the doors.

Fig. 1

Controls

Heater

(Fig ..1). A valve controlling the flow of coolant through the heater

unit

is fitted at the rear of the cylinder head. The valve is opened by turning it in

an

anti-clockwise direction when heating is required or shut off by turningclockwise

when the system is to be used for cool air ventilation.

Air flow (Fig. 2). The

knob

(1) operates a valve in the air intake

and

controls the

flow of air to the car interior.

Turn

the

knob

anti-clockwise from the

'OFF'

position to open the valve, the valve is fully

open

when the

knob

is turned to

Starting

Check

that

the gear lever is in the neutral position.

If

the engine is cold, pull out the mixture control (choke). In extremely cold

'conditions it may be necessary to pull the control

out

to its fullest extent. Lock

the control in the desired position by turning the control

knob

clockwise.

Switch on the ignition, check

that

the ignition'warning light glows and

that

the

fuel gauge registers, then operate the starter.

NOTE.-After

switching the igni-

tion on, the fuel gauge needle moves slowly across the scale, taking some 30

seconds to reach the true reading. This slow reaction eliminates needle flutter.

Loading...

Loading...