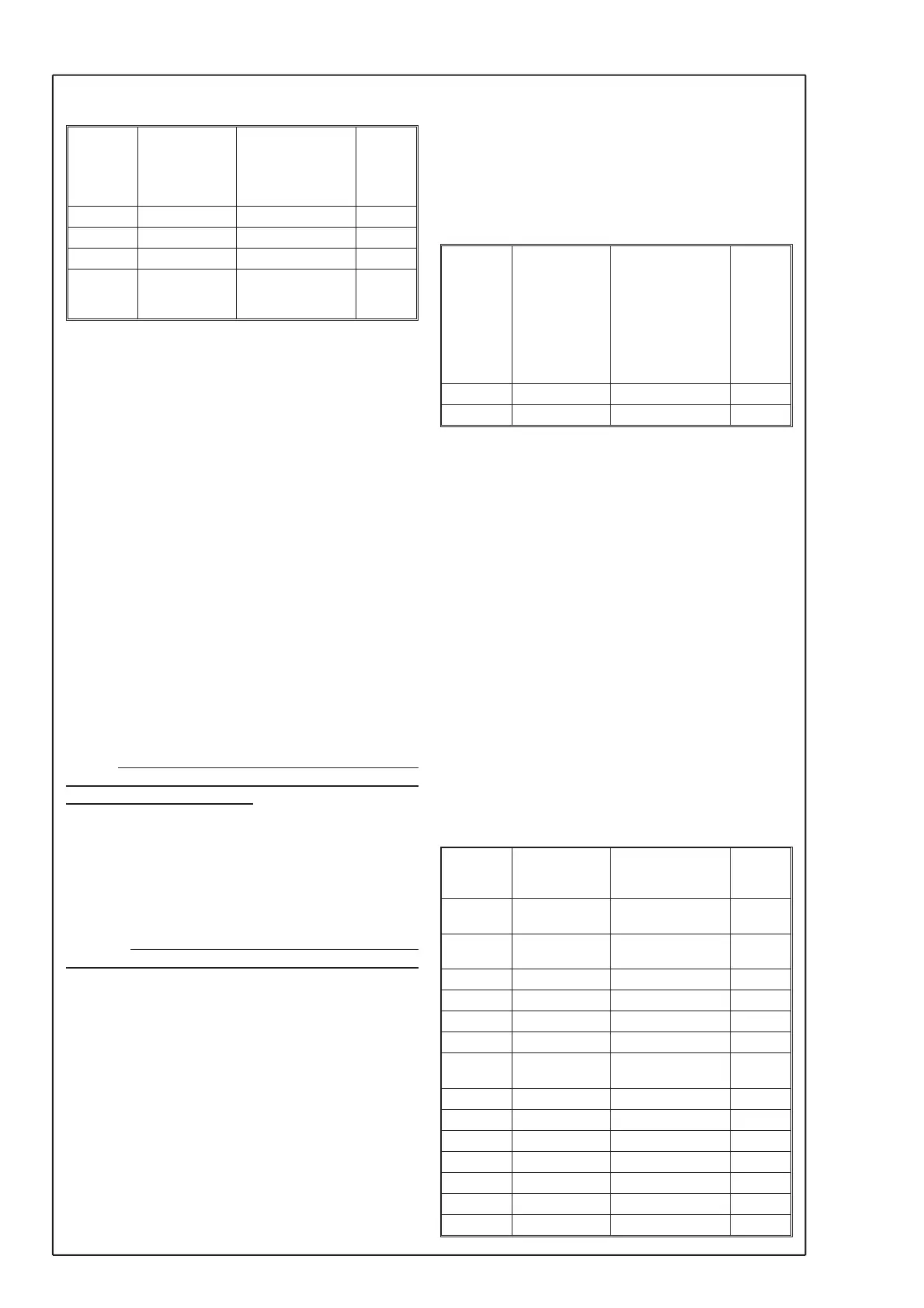

5. Flow

31 Unit flow L/s

m3/s

m3/h

m/s

cfm

32 Max flow 0...32767

33 Scale flw 0...32767

34 Set flow 0...32767

92 Compens OFF

ACTUAL

NORMAL 0

If the unit isn´t to be used for flow measurement,

nothing has to be programmed under the parameter

group “Flow”.

Programme the unit for flow l/s, m

3

/s, m

3

/h, m/s or

cfm (cubic feet / minute).

The basic flow calculation used is made with ÖdP.

To have the display and the output corresponding to

the actual flow or velocity in the selected unit it is

necessary to make some calculations.

Different manufactors of flow measurement devices

have different calculation, but common for all is ÖdP.

Use the actual formula to calculate the max flow for

the factory calibrated measure range. The calcu-

lated flow or velocity at 20 °C is then programmed

under “Max flow” in the selected unit. The flow

range for max. output signal is programmed in

"Scale flw”, e.g. 3,5 m

3

/s = 10 VDC.

In parameter "Scale Flw", the flow should be en-

tered at actual temperature or in normal flow if tem-

perature compensation is activated. The output sig-

nal is linear compared to the flow or velocity.

NOTE ! If the range is not scaled, the same value in

parameter "Max flow" must also be programmed

into parameter "Scale flw". When scaling the flow,

note that the accuracy depends on the “Max flow”

range.

If adjustment of the displayed actual flow or velocity

must be done, it is possible to do under “Set flow”.

Programme the actual flow coming from a reference

flow sensor or equal.

NOTE ! The programming must be done at the

same time as the reference values are measured

(PGM-key is pressed).

Automatically the “Max flow” programming will be

changed for the new values. If the unit is connected

to a BMS system or equal, the “Max flow” or if

scaled, the “Scale flw” and the output signal must be

programmed in the connecting system.

With the parameter "Compens", the calculated flow

can automatically be compensated for changes in

the air density due to temperature changes. With

the parameter set to "ACTUAL" the flow is calcu

-

lated by the current temperature. With the parame

-

ter set to "NORMAL 0", the flow will be calculated as

if the temperature was 0 °C.

When the parameter is set to "ACTUAL", the letter

"A" is displayed in front of the selected flow unit, e.g.

Am3/s, and when set to "NORMAL 0", the letter "N"

is displayed in front of the selcted flow unit, e.g.

Nm3/h. This is to indicate that the the flow is calcu

-

lated for the current temperature or in normal flow.

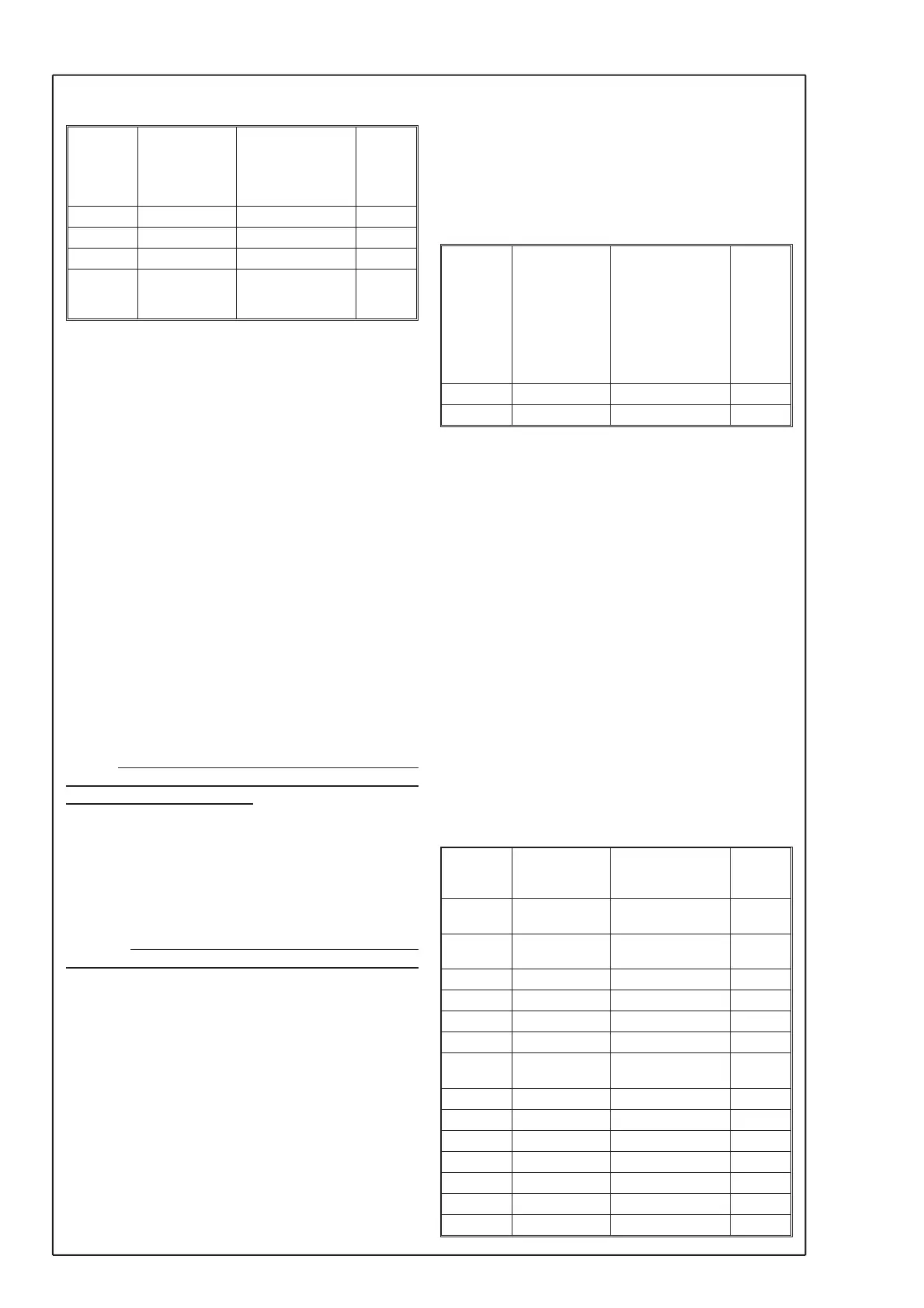

6. Temperature

93 Input OFF

0..10V

2..10V

0..20mA

4..20mA

Pt-100L

Pt-100H

Pt-1000L

Pt-1000H

94 Min Input -30...600

95 Max Input -30...600

Within this parameter group, the temperature sen

-

sor input is selected. It is possible to use an ana

-

logue signal, 0/2...10 VDC or 0/4...20 mA, Pt-100 or

Pt-1000 sensor.

When using an analogue signal the signal must be

scaled in parameter "Min Input" and "Max Input".

Pt-100 and Pt-1000 has two measuring ranges, ei-

ther low (L) or high (H).

The low selection has a temperature range of

-30...80 °C and the high selecting has a tempera-

ture range of 0...600 °C. The setting of parameters

"Min Input" and "Max Input" will automatically be set

for the low or the high range.

Change the setting of the DIL-switch located in the

upper right corner on the temperature input circuit

board, to correspond with the programmed settings,

VDC, mA, Pt-100 or Pt-1000. See figure on the last

page.

7. PI2 controller

35 Source OFF

dP

FLOW

36 Mode AUTO

HAND

37 Output DIRECT

REVERSE

52 Temp 1 -30...600

53 SP1 -32768...32767

54 Temp 2 -30...600

55 SP2 -32768...32767

56 SPC OFF

TEMP

39 NZ [%] 1...50

40 P-band 0...9999

41 I-time [s] 0...999

42 BZ [%] 0...100

43 I-time BZ 0...999

96 Min out 0,00...100,00

97 Max out 0,00...100,00

6

© AB MICATRONE 2009-02-12 [H:\ Apps \ Typeset \ Mima \ Mi-261gb_090212.vp]

Loading...

Loading...