3

Model SP-0125

1/8” Kerf Splitter - Green

Follow drawings under here Ð

Model SP-0100TK

Thin Kerf Splitter - Yellow

Follow drawings under here Ð

Hold –down

Clamp

P

r

e

s

s

u

r

e

n

e

x

t

t

o

D

r

i

l

l

G

u

i

d

e

o

n

l

y

.

R

i

p

F

e

n

ce

Micro Jig ZeroPlay™

Guide Bar Stop

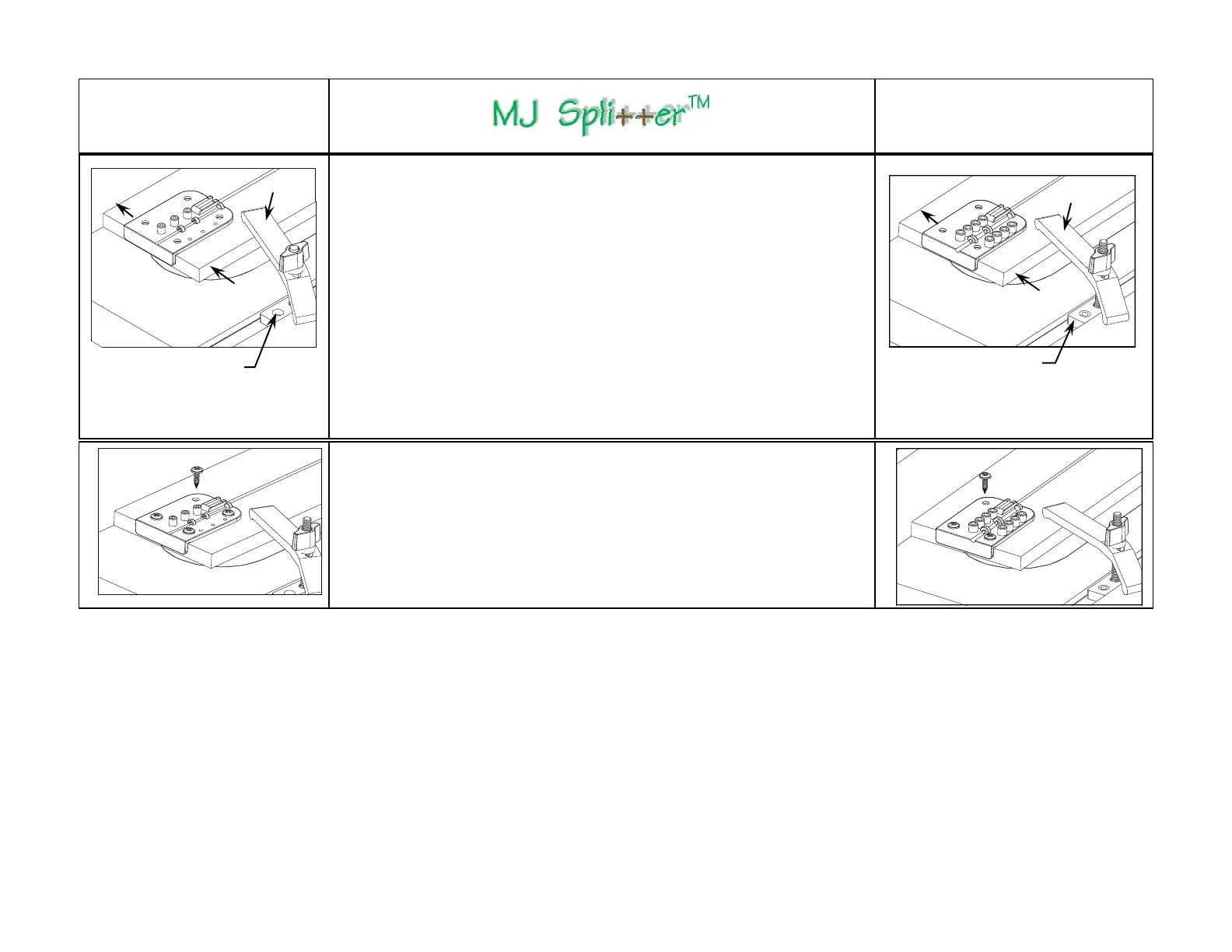

Step 4 - Securing the Setup Board

1) Lower the saw blade just below the Setup Board top surface without altering

the position of the Setup Board and the Drill Guide.

2) Clamp the Setup Board in position while applying firm finger or light feather

board pressure on the Setup Board against the fence so that the Drill Guide is

tight in the saw kerf. This ensures that the right edge of the bottom rib on the

Drill Guide is in full contact with the right edge of the saw kerf. This will also

align the centers of the guide holes at the pre-determined distance from and

parallel to the right edge of the saw kerf, regardless of the actual width of the

saw kerf. (Vibration will inevitably cause the saw kerf to be slightly wider than

the width of your saw blade.)

Note: The illustration shows a fast and simple way of clamping the Setup

Board by using a Hold-Down Clamp and the Stop from Micro Jig’s ZeroPlay™

Guide Bar System. You may also clamp a board bridged over the Setup Board

from the edge of your table saw top.

Hold –down

Clamp

R

i

p

F

e

n

ce

Micro Jig Zero-

Play™ Guide Bar Stop

P

r

e

s

s

u

r

e

n

e

x

t

t

o

D

r

i

l

l

G

u

i

d

e

o

n

l

y

.

R

i

p

F

e

n

c

e

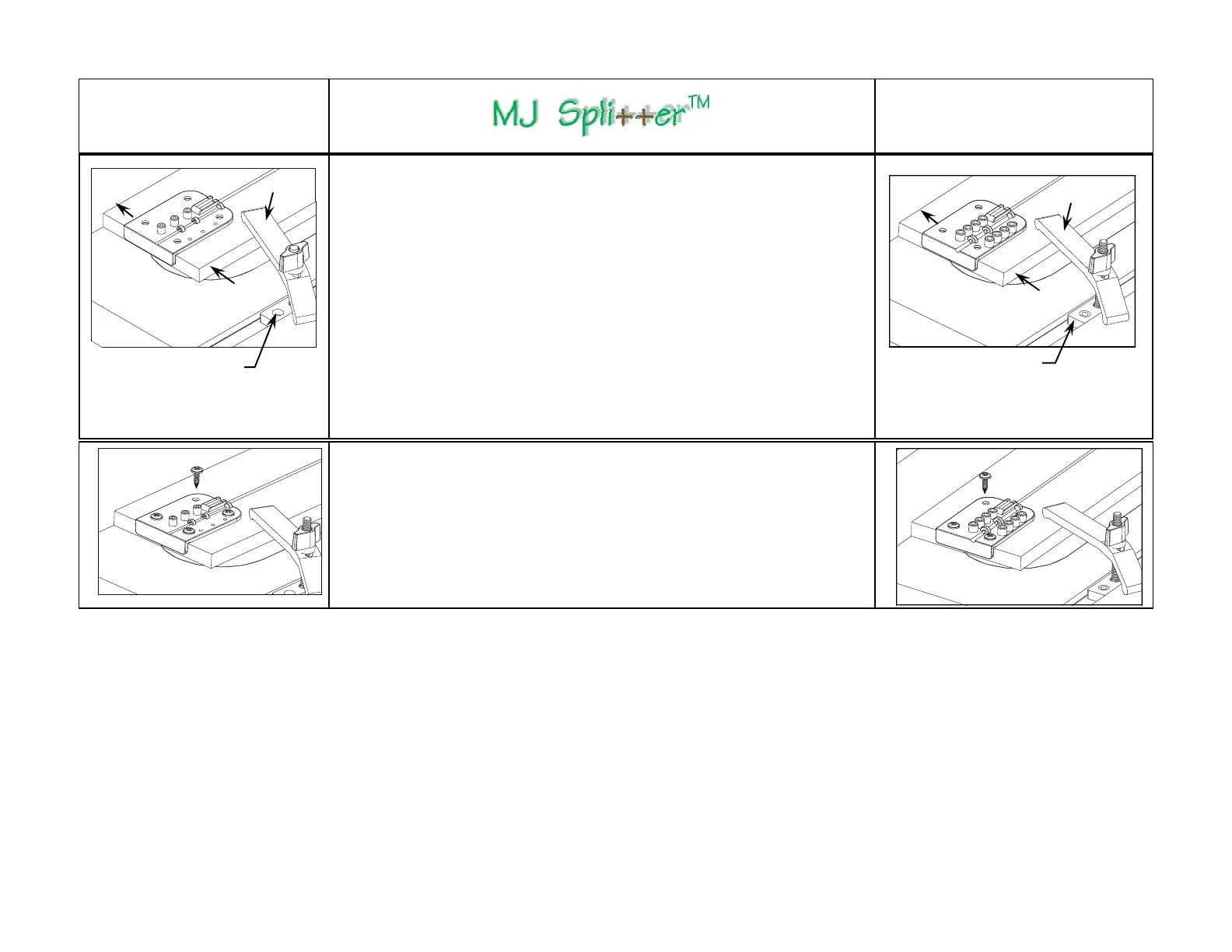

Step 5 - Securing the Drill Guide

1) Secure the Drill Guide onto the Setup Board using (4) #8 x 1/2" wood screws

(provided). Pilot holes are not required if you use a power hand drill (the bottom of

the screw holes are countersunk to accommodate any swarf from the drilling opera-

tion). DO NOT drive the screws all the way with the power drill to prevent stripping

the threads - lightly tighten the screws with a Robertson or Phillips screwdriver.

2) If you prefer pilot holes, use a 1/8” drill bit to drill the pilot holes NOT MORE than

1/8" deep, and lightly tighten the screws by hand.

Loading...

Loading...