VC Pro VRF 50/60Hz

179

Part 3 - System Design and Installation

8 Charging Refrigerant

8.1 Calculating Additional Refrigerant Charge

The additional refrigerant charge required depends on the lengths and diameters of the outdoor and indoor liquid pipes.

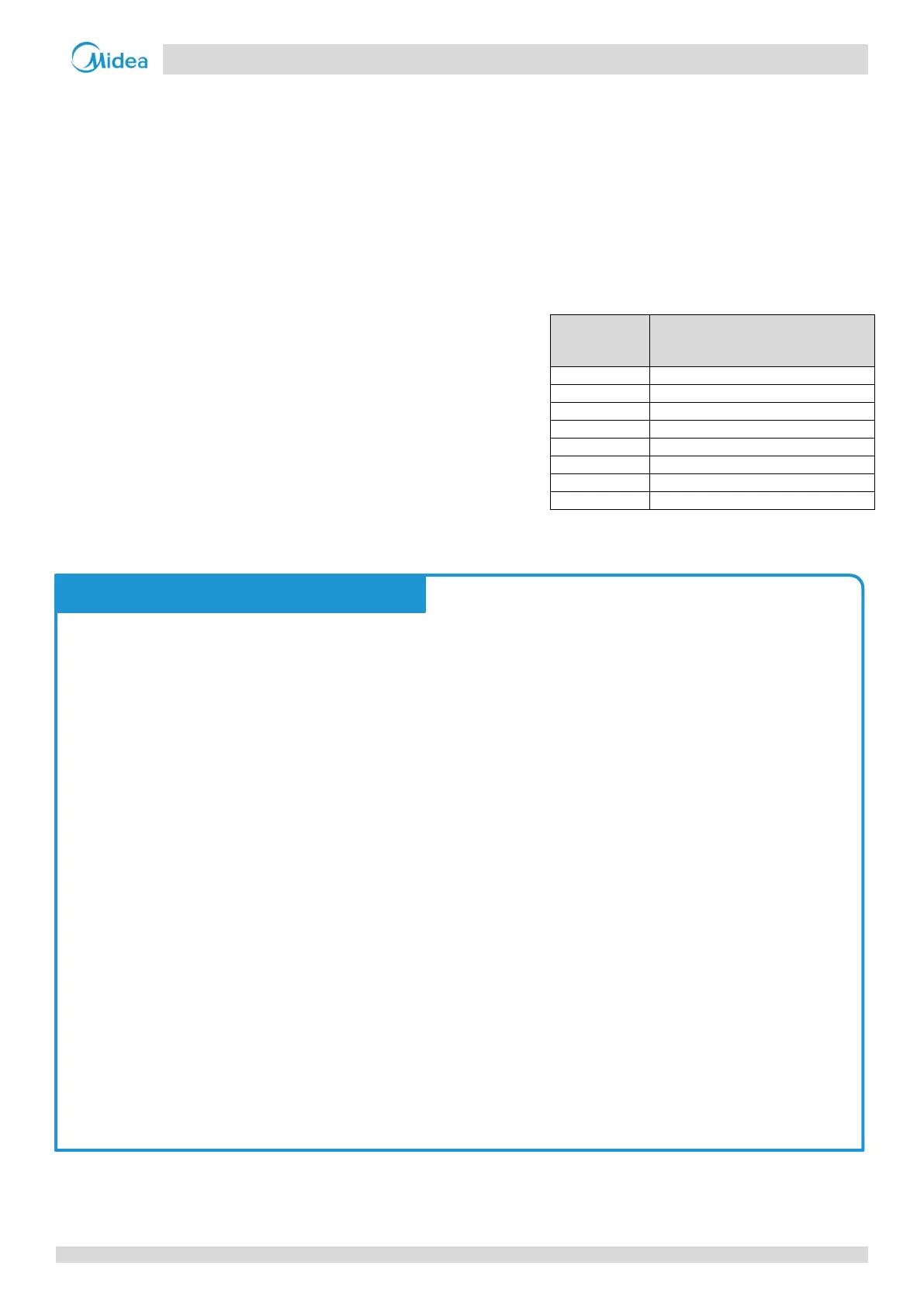

Table 3-8.1 shows the additional refrigerant charge required per meter of equivalent pipe length for different diameters of

pipe. The total additional refrigerant charge is obtained by summing the additional charge requirements for each of the

outdoor and indoor liquid pipes, as in the following formula, where L

1

to L

8

represent the equivalent lengths of the pipes of

different diameters. Assume 0.5m for the equivalent pipe length of each branch joint.

Additional refrigerant charge R (kg) = L

1

(Φ6.35) × 0.022

+ L

2

(Φ9.53) × 0.057

+ L

3

(Φ12.7) × 0.110

+ L

4

(Φ15.9) × 0.170

+ L

5

(Φ19.1) × 0.260

+ L

6

(Φ22.2) × 0.360

+ L

7

(Φ25.4) × 0.520

+ L

8

(Φ28.6) × 0.680

8.2 Adding Refrigerant

Box continued on next page …

Table 3-8.1: Additional refrigerant charge

Additional refrigerant charge per

meter of equivalent length of

piping (kg)

Caution

Only charge refrigerant after performing a gastightness test and vacuum drying.

Never charge more refrigerant than required as doing so can lead to liquid hammering.

Only use refrigerant R410A - charging with an unsuitable substance may cause explosions or accidents.

Use tools and equipment designed for use with R410A to ensure required pressure resistance and to prevent

foreign materials from entering the system.

Refrigerant must be treated in accordance with applicable legislation.

Always use protective gloves and protect your eyes when charging refrigerant.

Open refrigerant containers slowly.

Procedure

The procedure for adding refrigerant is as follows:

Step 1

Calculate additional refrigerant charge R (kg) (see Part 3, 8.1 “Calculating Additional Refrigerant Charge”)

Step 2

Place a tank of R410A refrigerant on a weighing scale. Turn the tank upside down to ensure refrigerant is charged

in a liquid state. (R410A is a blend of two different chemicals compounds. Charging gaseous R410A into the

system could mean that the refrigerant charged is not of the correct composition).

After vacuum drying (see Part 3, 5.10 “Vacuum Drying”), the blue and red pressure gauge hoses should still be

connected to the pressure gauge and to the master unit stop valves.

Connect the yellow hose from the pressure gauge to the R410A refrigerant tank.

Loading...

Loading...