7

D

Using switch labeled INC. / DEC. Push

switch up or down . Number will increase

or decrease accordingly.

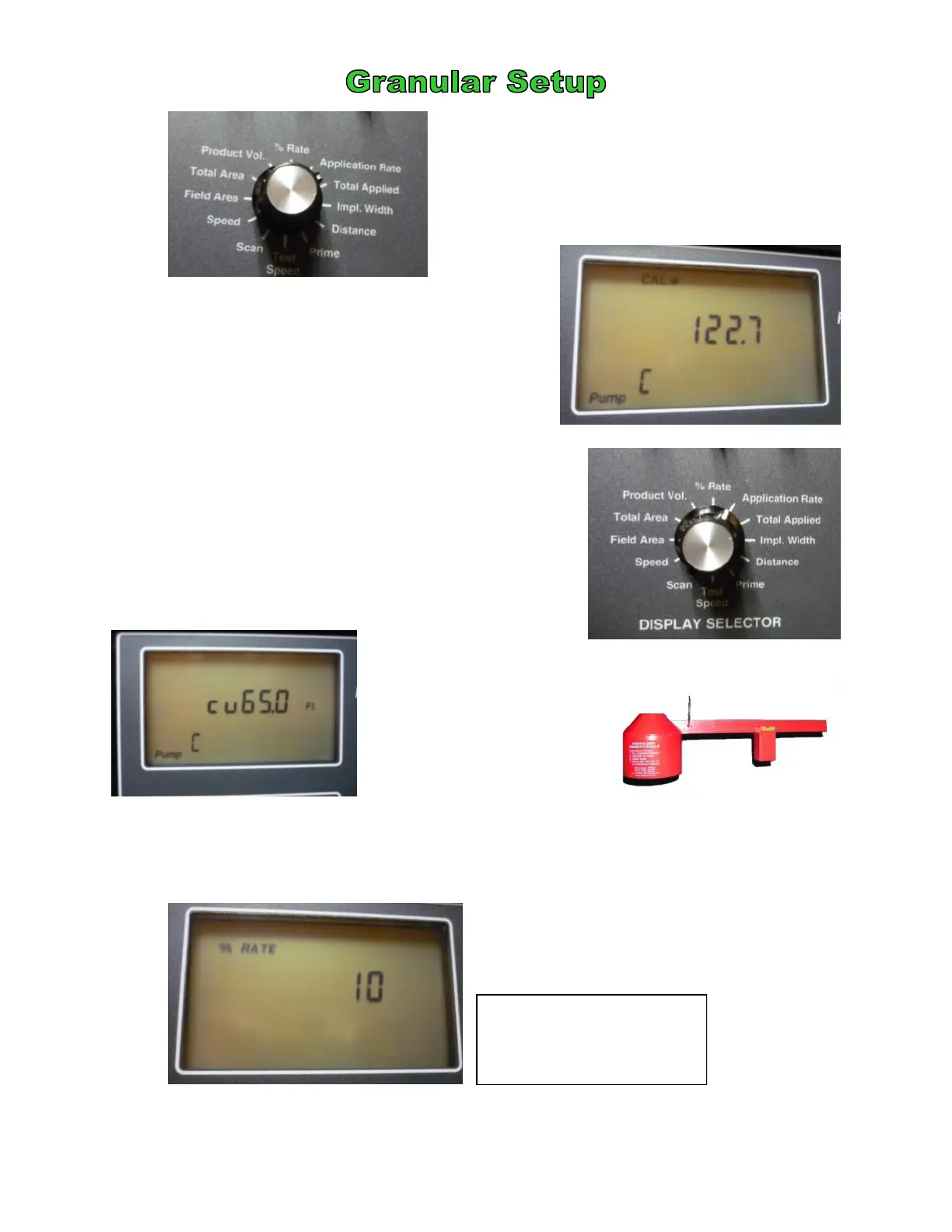

Twist Display Selector to Total Applied

The spreader constant number must be

checked. The gate height must match the

constant chosen.

Using conveyor width & type plus encoder

type NCI has a chart to obtain this number.

E

Twist Display Selector to Application Rate

Using switch labeled INC. / DEC. Push switch up or

down . Number will increase or decrease accordingly.

Product density should be measured & entered

with each load.

NCI sells a density scale

(SM-DS-50895)that will

give you the correct

number for your load.

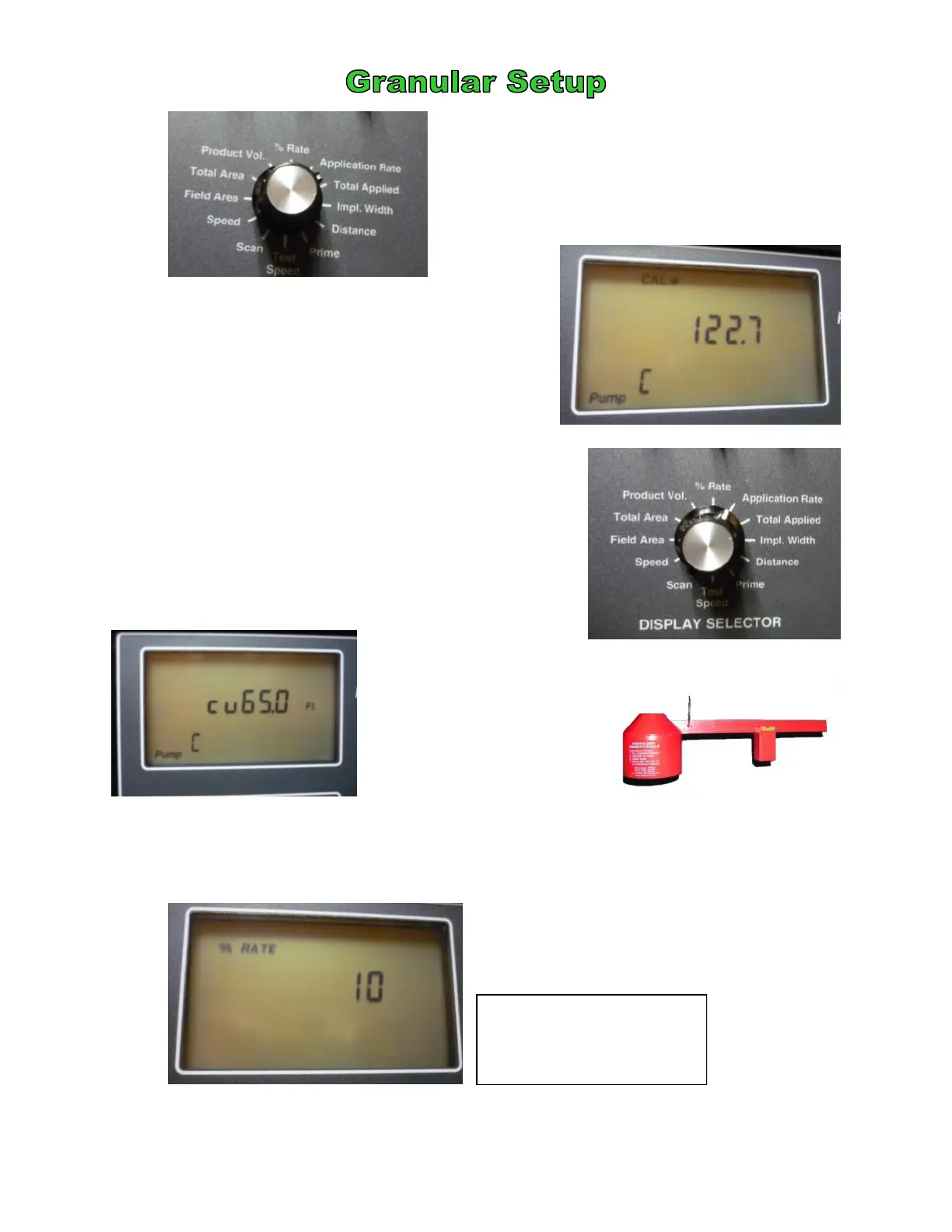

This is the amount of deviation from your

desired application rate that you allow. It

changes in increments of 10.

Usually, it is not desirable to have your

spread rate deviate substantially.

F

Twist Display Selector to % Rate

This is your product density entered in lbs/cu ft.

Incorrect product density will cause your application rate to be incorrect

ALWAYS return to 100% in the Operate Mode or your entire job will be incorrect!!

©2011 Newton Crouch Inc. This information is the property of Newton Crouch Inc. and is loaned confidentially to our customer for his sole use. It must not be used in any way

detrimental to our interest or shared with outside parties. Technical Tips/ ARC6000 Programming—Dry Rev 2.2.2011

This setting allows for

110% I—the desired rate

plus 10%

Loading...

Loading...