Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

dealer or Milnor. Possible causes are as follows:

• a blockage or a leak in the air tube,

• a worn pilot air valve,

• worn components in the mechanism,

• air pressure supplied to the machine is not sufficient,

• a component used to remove contamination from the air line is clogged,

• a quick exhaust valve or muffler is clogged,

• on machines with an air line lubricator, a malfunction or incorrect adjustment prevents

sufficient lubrication.

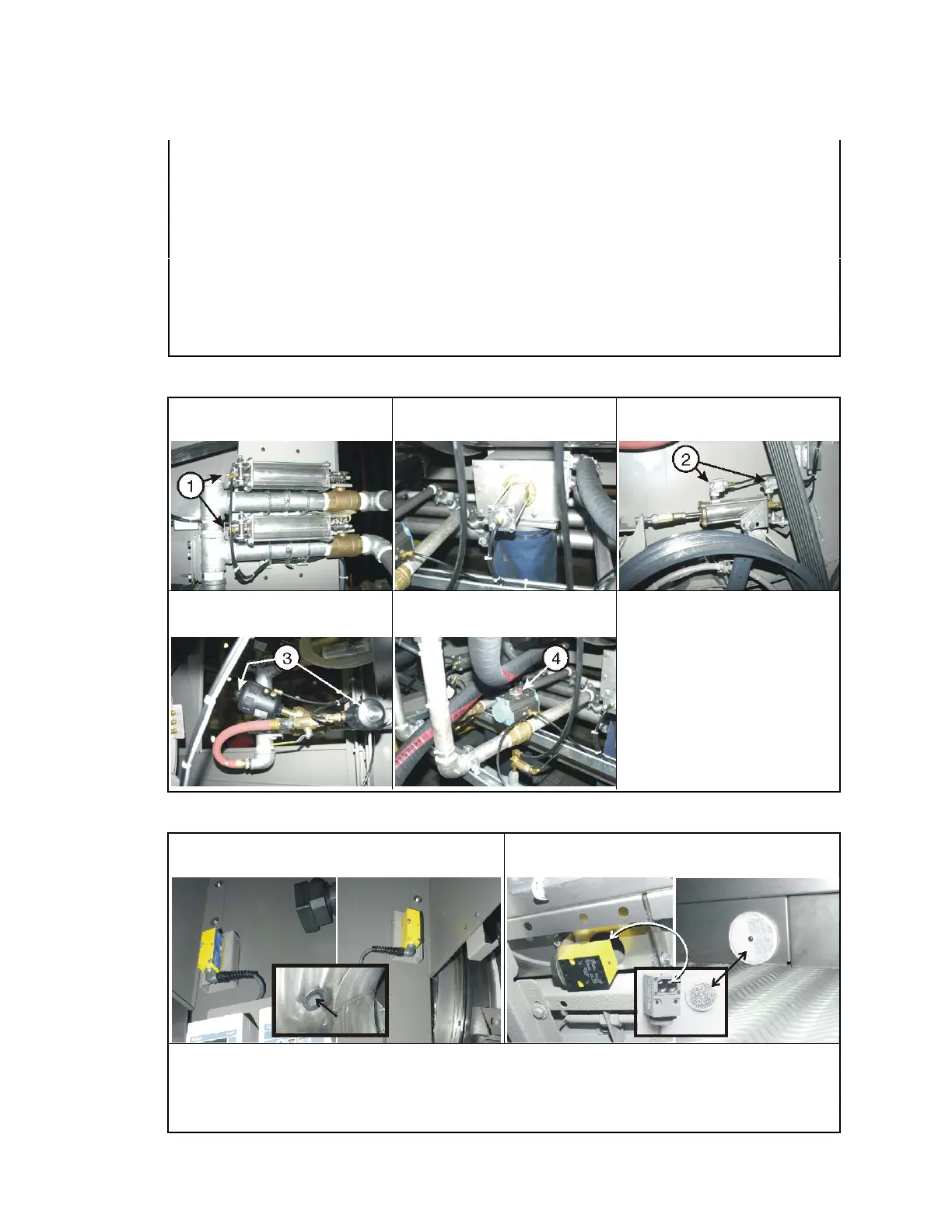

Figure 17: Compressed Air Mechanisms. These are examples. Your machine can look different.

Air Operated Water Valves -

Milnor Air Cylinder Type

Air Operated Drain Valve -

Milnor Air Cylinder Type

Air Operated Band Brake -

Milnor Air Cylinder Type

Air Operated Water and

Steam Valves - Angle Type

Air Operated Water Valve -

Ball Valve Type

Legend

1. Factory-set needle valves

to cause two air cylinders

to move together. Do not

adjust.

2. Quick exhaust valves

3. Position indicator. Yellow

when valve is open.

4. Arrow position indicator

.

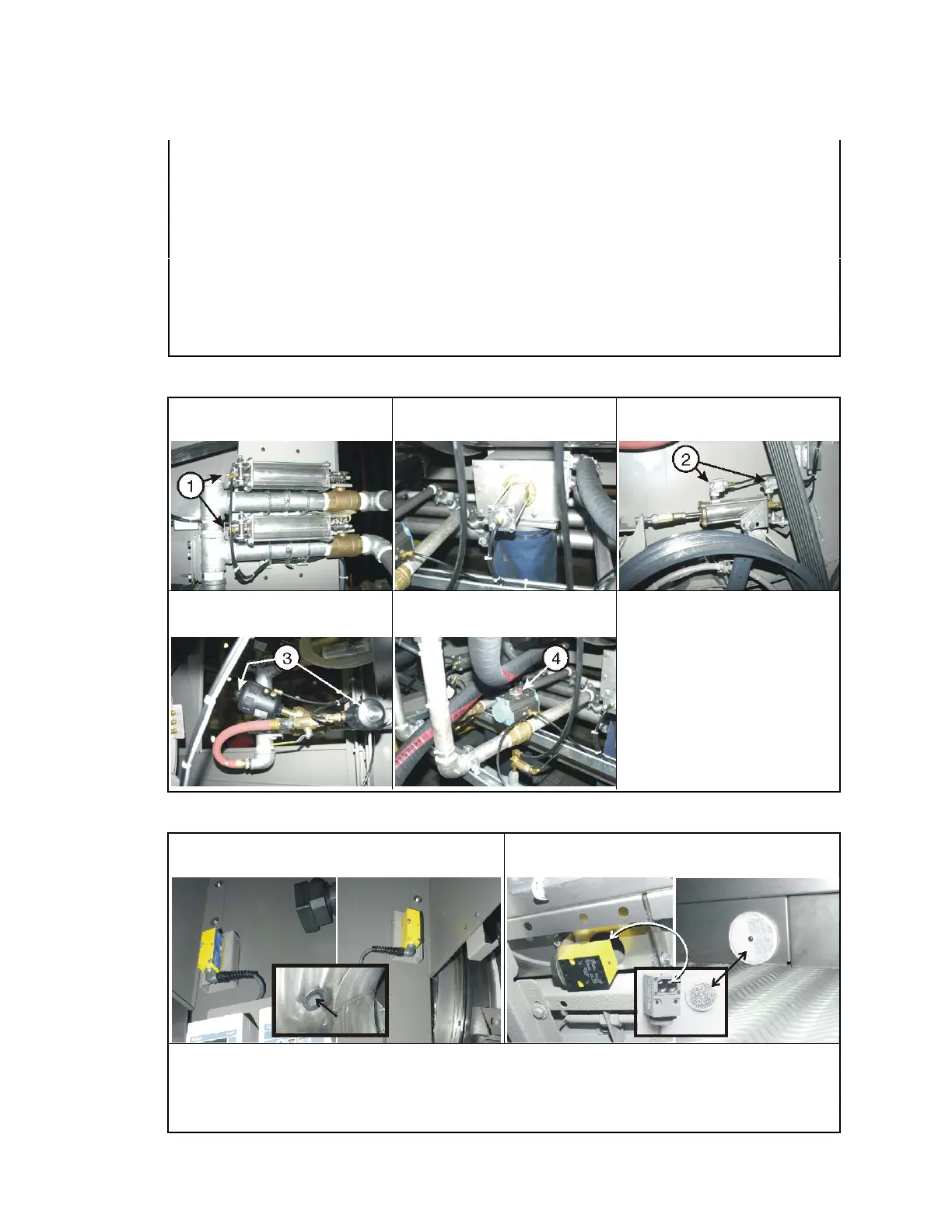

Figure 18: Photoeyes. These are examples. Your machine can look different.

Photoeye protected by a site glass, each

side of the CBW load chute

Photoeye and reflector on extractor

discharge conveyor

Legend

→. Exposed surfaces that must be clean. Remove contamination with a soft cloth. If the surface is

hard to touch, use a cloth on the end of a wood dowel or metal rod. If necessary, use a safe

cleaning agent.

.

42

Loading...

Loading...