Disk Brake Maintenance

PELLERIN MILNOR CORPORATION

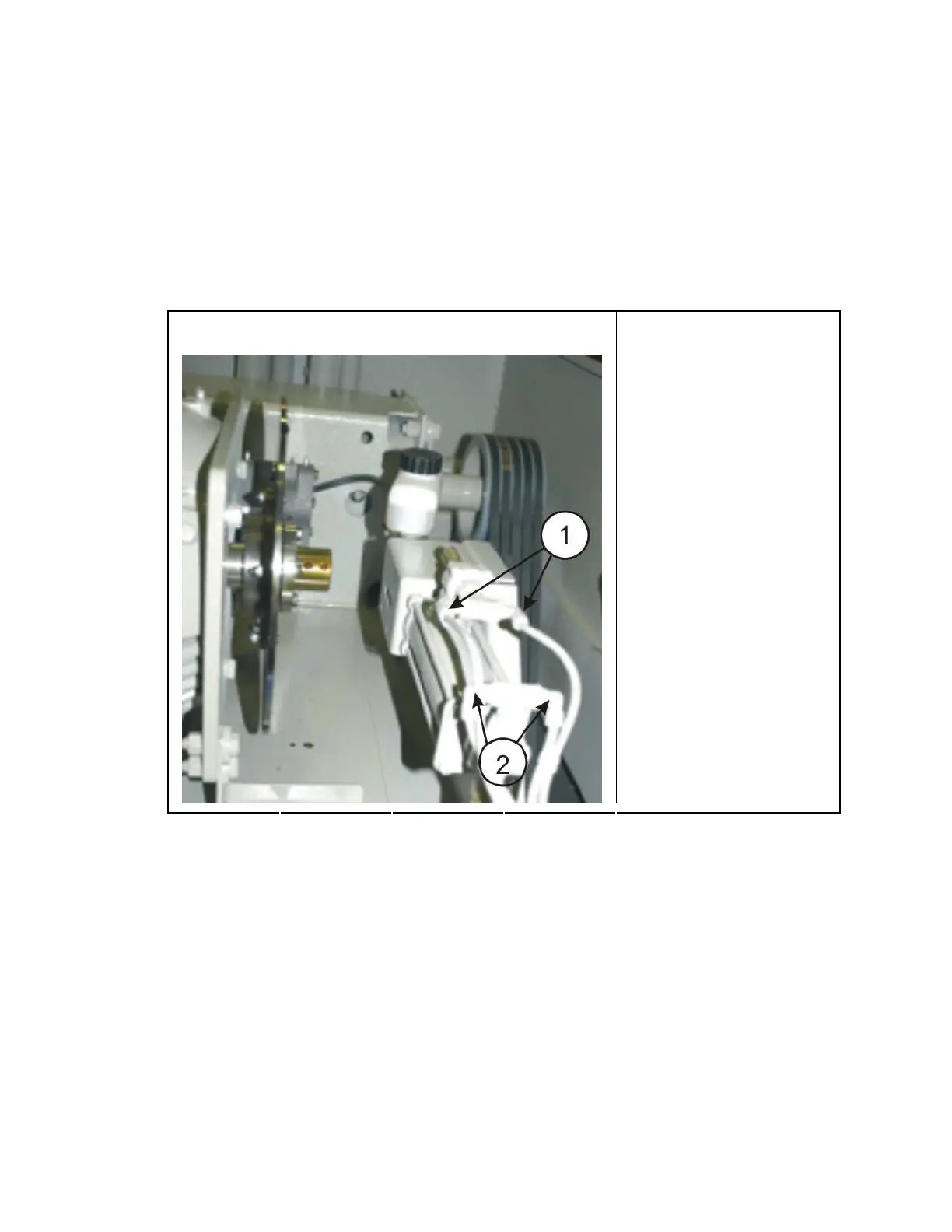

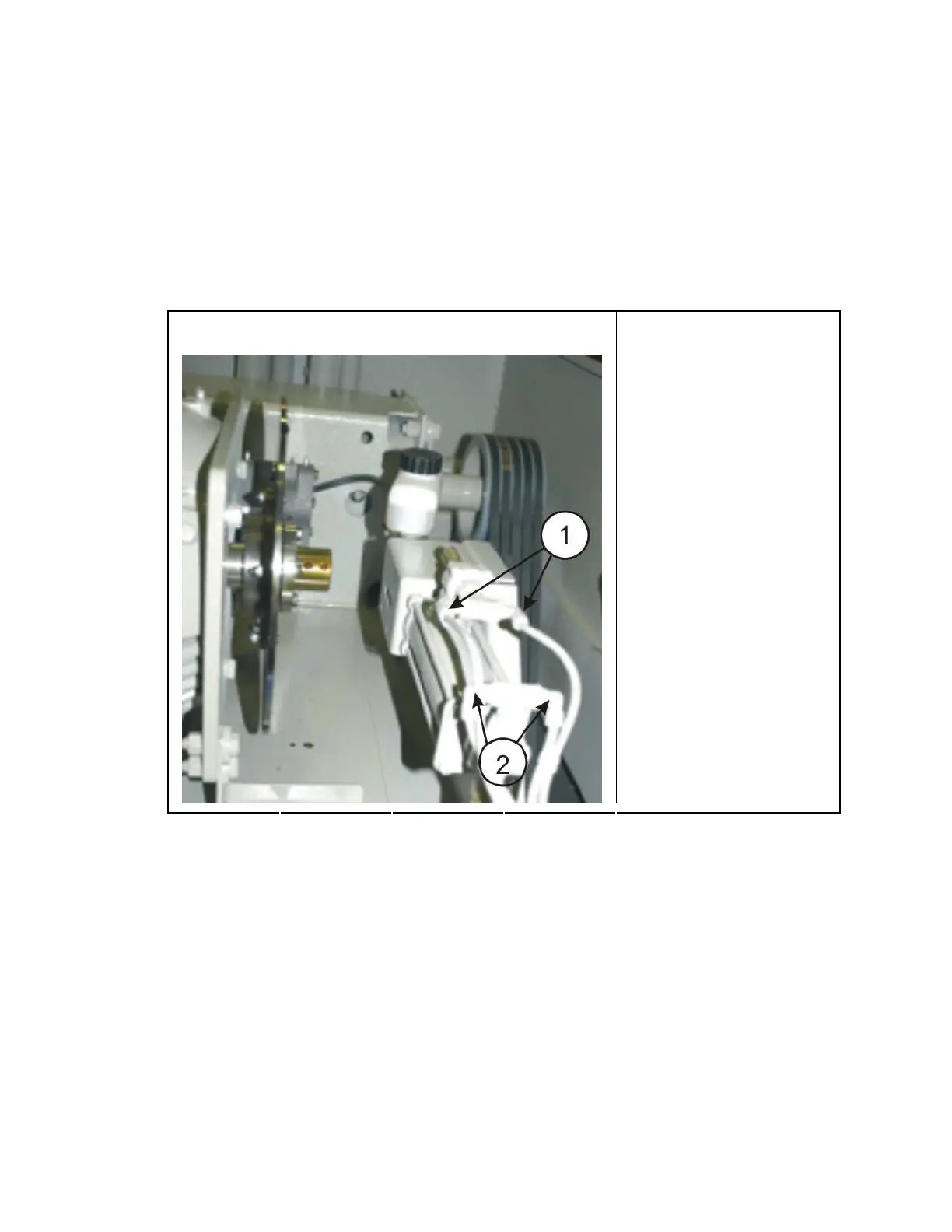

2. Turn the "brake release" output on. The air valve will supply compressed air to one of the

tubes. (Figure 1, item 1).

3. Quickly move one of the compressed air tubes (Figure 1, item 1) on and off the air cylinder.

4. After you complete this procedure, connect the air tubing.

6.4.

How the Brake Operates on Divided Cylinder Machines

Figure 7: A Typical First and Second Brake on a Divided Cylinder Machine

Two pairs of air tubing connect to different ends of the air

cylinder.

Legend

.

1. Tubing for air that releases

the first brake ( 85 -100

PSI) ( 5.95 - 07.0 kg/cm-

cm)

2. Tubing for air that applies

the second brake (10 – 12

PSI) (0.7-0.84 kg/cm-

• On divided cylinder machines, two pair of air tubes connect to different ends of the air

cylinder.

• When the cylinder turns, air pressure at Figure 7, item 1 compresses the spring and releases

the brake.

• When you operate the stop control, air pressure at 1 is removed. Then the spring in the air

cylinder applies the brake.

• If you open the door, the 2nd brake is applied. Then the air pressure at Figure 7, item 2 and

the spring apply the brake.

6.5.

The Second Brake —If your machine has a second brake which uses air pressure and

spring pressure, it will have a pressure regulator. Make sure that you adjust the air pressure of the

second brake (Figure 7, item 2) to 10 – 12 PSI (0.7-0.84 kg/cm-cm).

— End of BIEUUM01 —

89

Loading...

Loading...