4

5

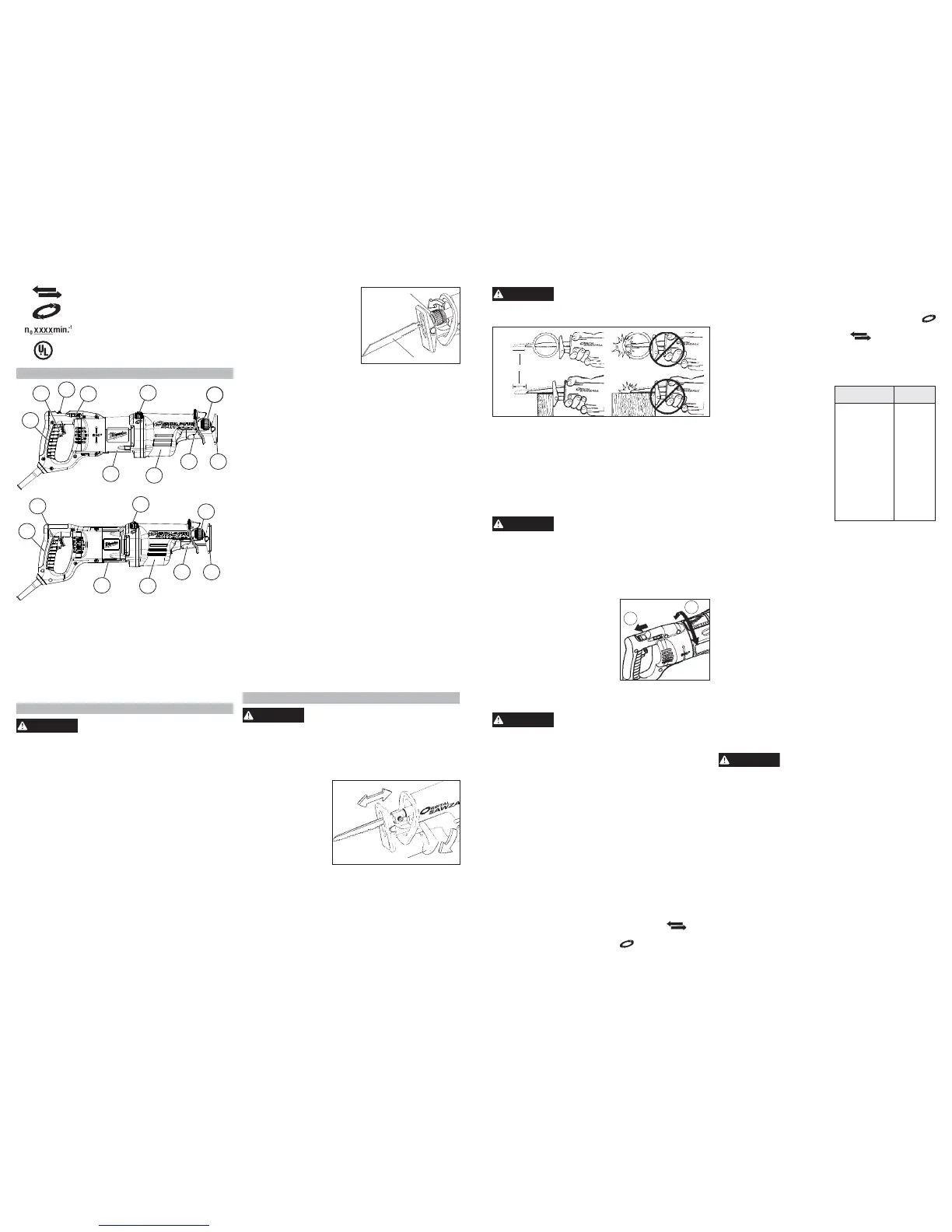

1. Depending on the job, the

Blade

Collar

blade may be inserted with

the teeth facing up or

down. To install a blade,

twist collar in the direction

of the arrow while inserting

the blade into the clamp

until the tang butts against

the collar.

2. Release collar and the spring loaded mechanism

will clamp the blade fi rmly in place.

3.

Twist collar in the opposite direction of the arrow to

ensure that the blade is locked into the clamp.

4. Tug on blade to make sure it is securely locked in

place.

5.

To remove a blade, twist collar in the direction of the

arrow while pulling on the blade. Be careful when

handling hot blades.

Quik-Lok

®

Blade Clamp Maintenance

• Periodically clean dust and debris from the Quik-Lok

®

Blade Clamp with dry compressed air

.

•

If the collar resists twisting, twist it back and forth to

shake debris loose.

• Periodically lubricate Quik-Lok

®

Blade Clamp with dry

lubricant such as graphite.

Removing broken blades from the

Quik-Lok

®

Blade Clamp

Unplug the tool before removing blades. Broken blades

can be removed by the following methods.

• Point the tool downward, twist the collar, and shake the

tool up and down (do not turn the tool on while your

fi ngers are holding the blade clamp open). The shank

of the broken blade should drop out of the clamp.

• If shaking the tool doesn't work:

In most cases, a corner of the broken blade will extend

beyond the blade clamp. Simply twist the collar and

pull the broken blade out of the clamp by this corner.

• If the broken stub doesn't extend far enough to be grabbed

by its corner, use a thin blade with small teeth (such as

a metal cutting blade) to hook the blade that is jammed

in the clamp while twisting the collar and pull it out.

OPERATION

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

Adjustable Pivot Shoe

The shoe can be adjusted forward or backward to six

positions to take advantage of the unused portion of the

blade or for special jobs requiring low blade clearance.

1. To adjust the shoe,

1/4 Turn

pull the shoe re-

lease lever down

1/4 turn and slide

the shoe forward or

backward to the

desired position.

2.

To

lock the shoe in

position, push the

shoe release lever

up.

3. After adjusting the shoe, slowly pull the trigger to be

sure the blade always extends beyond the shoe and

your work throughout the stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE.

STRIKING THE SPINDLE AGAINST WORK MAY

DAMAGE THE RECIPROCATING MECHANISM.

WARNING

To reduce the risk of injury, be sure

the blade always extends beyond

the shoe and work throughout the stroke. Blades

may shatter if they impact the work or shoe.

Stroke

Impact Protection System

All models are equipped with a unique patented

gearing system that provides effi cient power trans-

mission and extended life in the most diffi cult cut-

ting applications. This durable system will absorb

impacts, blade lock ups, and motor stalls. These

models can be used for extreme cutting applications

such as large diameter pipe, thick metal, pallets, and

heavy demolition and renovation work as well as for

general purpose cutting.

WARNING

Do not operate the Sawzall

®

with the

handle rotation button pressed in or

with the handle not locked into position.

Rotating the Handle (Cat. No. 6523-21)

The 6523-21 Sawzall

®

handle can rotate continu-

ously in either direction, allowing the user to achieve

optimal cutting positions and comfort. The handle can

be locked into one of eight (8) detent positions, one at

every 45° angle.

To rotate the

handle:

2

1

1. Unplug the tool.

2. Press in the handle rotation

button.

3

. Rotate the handle to the

desired position.

4. Release the handle rotation

button. This will lock the

handle fi rmly into position.

NOTE: Make sure the handle does not rotate before

using the tool.

WARNING

If the handle can not be locked into

position, do not operate the

Sawzall

®

. Return the Sawzall

®

to a MILWAUKEE

service facility immediately for repair.

To reduce the risk of personal injury, always hold

tool securely.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handle fi rmly and pull the

trigger.

2. To stop the tool, release the trigger. Allow the tool to

come to a complete stop before removing the blade

from a partial cut or laying the tool down.

Orbit Control Switch

These Sawzalls

®

are equipped with an orbit control

switch. The tool may be operated with straight recipro-

cating (non orbital) or orbital action. Straight reciprocat-

ing action should be used when a smooth cut is needed.

Orbital action is recommended for fast, aggressive

cutting. The optimal orbital action should be determined

by the user for their specifi c cutting requirements.

1. For straight reciprocating action, move the orbit

control switch to the straight cut symbol

.

2.

For orbital action, move the orbit control switch to-

wards the orbital cut symbol

.

Straight Cut

Orbital Cut

No Load Strokes per Minute (SPM)

C

US

Underwriters Laboratories, Inc.

United States and Canada

FUNCTIONAL DESCRIPTION

5

7

8

9

10

1

3

Cat. No. 6523-21

6538-21

2

Cat. No. 6520-21

6536-21

11

6

6

11

10

10

9

8

7

3

4

1. Speed control dial

2. Handle rotation button (6523-21 only)

3. Trigger

4. Handle

5. Rotating handle (6523-21)

6. Nameplate

7. Insulating boot (gripping surface)

8. Shoe release lever

9. Adjustable pivot shoe

10. Quik-Lok

®

blade clamp

11. Orbit control switch

ASSEMBLY

WARNING

To reduce the risk of injury, always

unplug tool before changing or re-

moving accessories. Only use accessories spe-

ci

fi

cally recommended for this tool. Others may be

hazardous.

Selecting a Blade

Use MILWAUKEE Sawzall

®

Blades for best perfor-

mance. When selecting a blade, choose the right type

and length. Many types of blades are available for a

variety of applications: cutting metal, wood, nail-em-

bedded wood, scroll cutting, roughing-in, and contours.

Many lengths are also available. Choose a length long

enough to extend beyond the shoe and your work

throughout the stroke. Do not use blades less than

3-1/2" long since they won't extend beyond the

shoe throughout the stroke.

For best performance and longest life, see “Acces-

sories” to select the best blade for the job.

Quik-Lok

®

Blade Clamp

Unplug the tool before changing blades. Be sure the

spindle and blade clamp areas are clean. Metal chips

and sawdust may prevent the Quik-Lok

®

Blade Clamp

from clamping securely.

The amount of orbital action may be adjusted by mov-

ing the orbital control switch to any position between

the two symbols. For larger orbital action, move the

orbit control switch closer to the orbital cut symbol

. For smaller orbital action, move the orbit control switch

closer to the straight cut symbol

.

Orbital action may be adjusted when the tool is running.

NOTE: Orbital action will not operate if the blade is

installed upside down.

Selecting the Speed Range

The speed control dial controls

MATERIAL

DIAL

SETTING

Mild Steel

Wood

Nail-Embedded

Wood

Stainless Steel

Drywall

Fiberglass

Plastics

Cast Iron

Non-Ferrous

Metals

2-3

5

5

1-3

4-5

1-3

1-3

2-3

2-3

the maximum strokes per

minute. The speed will re-

main variable to the chosen

dial setting by use of the

trigger switch. Refer to the

chart for recommended dial

settings.

*These are only suggested set-

tings; the actual optimal setting

may vary depending on line

voltage, blade selected and

user preference.

Trigger Speed Control Switch

These Sawzalls

®

are equipped with a trigger speed

control switch. It may be operated at any speed from

zero strokes per minute to full speed. Always start tool

before blade contacts the workpiece. To vary the speed,

simply increase or decrease the pressure on the trigger.

The further the trigger is pulled, the greater the speed.

To stop the tool, release the trigger and allow the tool

to stop completely before removing from a partial cut

or before laying the tool down.

General Cutting

For straight or contour cutting from an edge, line the

blade up with your cutting line. Before the blade con-

tacts the workpiece, grasp the handle fi rmly and pull

the trigger. Then guide the tool along your cutting line.

Always hold the shoe fl at against the workpiece to avoid

excessive vibration.

Cutting Metals

Begin cutting at a slow speed, gradually increasing

speed as you cut. When cutting into metals or hard

materials that can not be cut from an edge, drill a

starting hole larger than the widest part of the blade.

Extend blade life by using a solid blade cutting lubricant.

WARNING

To reduce the risk of explosion,

electric shock and property damage,

always check the work area for hidden gas pipes,

electrical wires or water pipes when making blind

or plunge cuts.

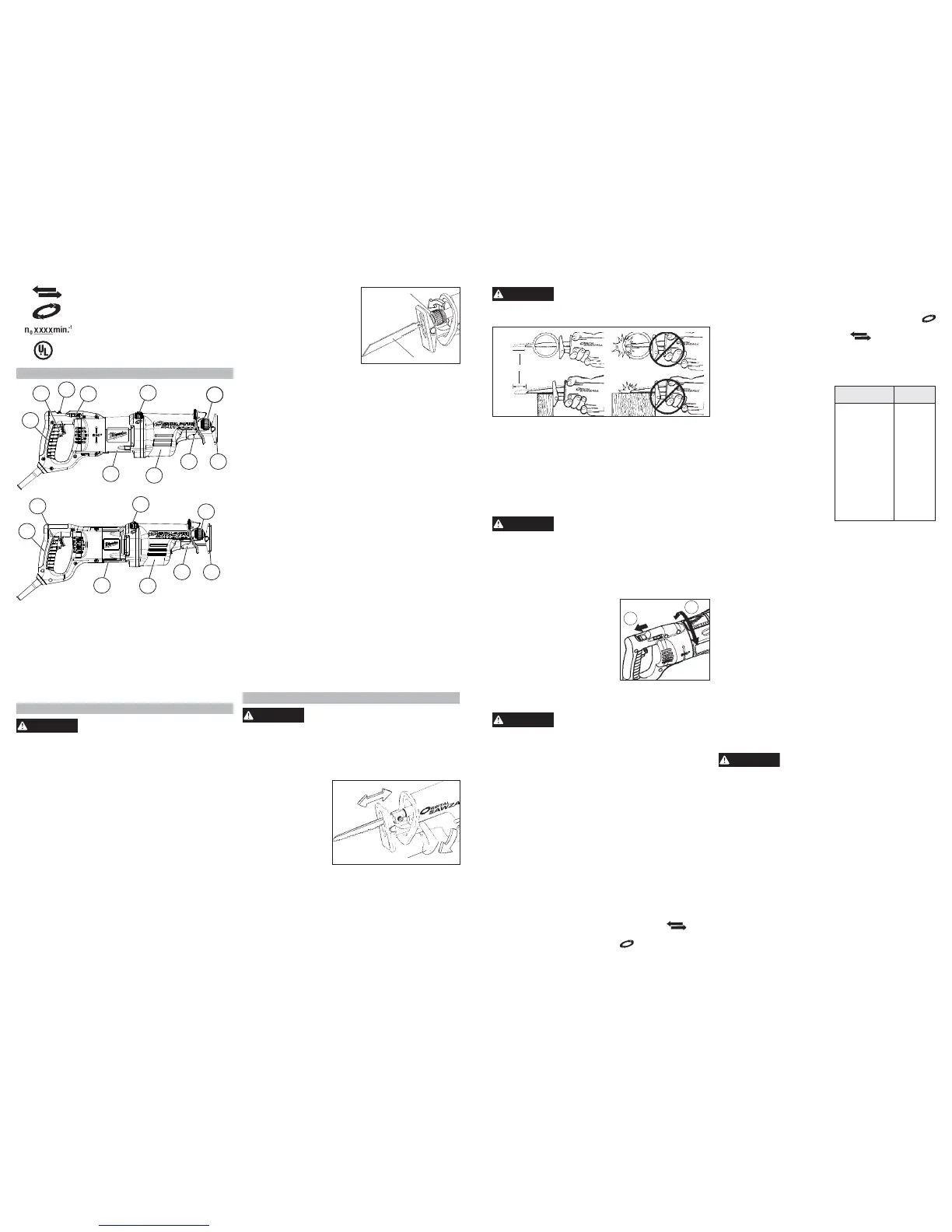

Plunge Cutting

Your MILWAUKEE Sawzall

®

is ideal for plunge cutting

directly into surfaces that can not be cut from an edge,

such as walls or fl oors. Orbital action is recommended

for plunge cutting. Plunge cutting may be done two

ways depending on how the blade is inserted. Column

A shows how to plunge cut with the teeth of the blade

facing down. Column B shows how to plunge cut with

the teeth of the blade facing up.

NOTE: Orbital action will not operate if the blade is

installed upside down.

Do not plunge cut into metal surfaces (see “Cutting

Metals”).

1. Insert the blade into the tool.

If you inserted the blade with the teeth facing down-

Loading...

Loading...