■

ADJUSTING THE CARBURETTOR

The carburettor has been factory adjusted, but may require fine tuning due to a change in operating conditions.

Carburettor adjustments should be made by the supplying dealer using specialist tools as follows.

• Make sure that the air filter and fuel filter are clean, and the fuel is freshly mixed.

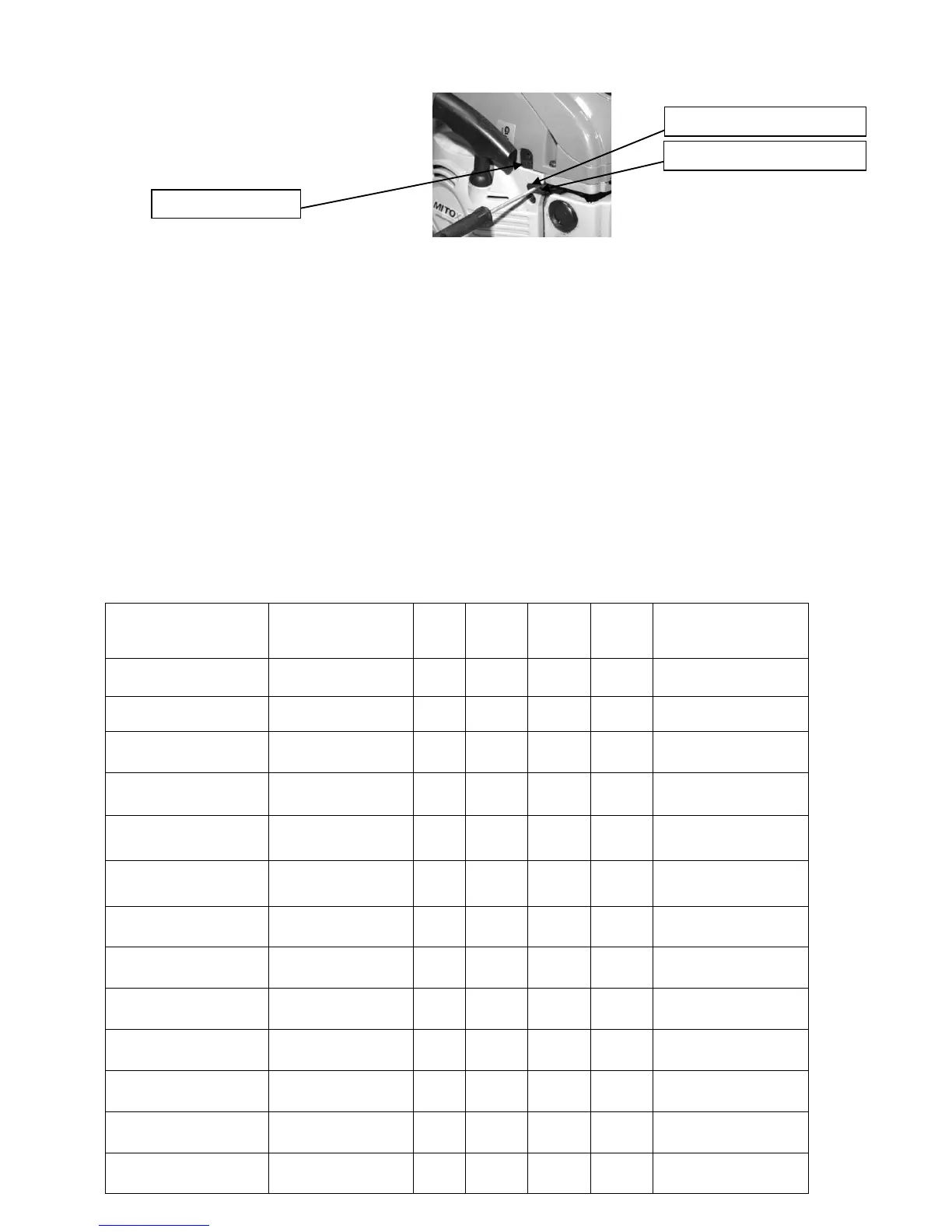

• Stop the engine and screw in both the H and L needles until they stop. Never force them. Then set them back

the initial number of turns as shown below.

H screw: 1 +or-¼

L screw: 1 ¼ +or-¼

1. Start the engine and allow it to warm up at half-throttle with saw chain and guide bar fitted.

2. Turn the L screw slowly to find a position where idling speed is at maximum, then set the L adjusting screw

back a quarter (1/4) turn (counter clockwise).

3. Turn the idle adjusting screw T counter clockwise so that the saw chain does not turn. If the idling speed is

too slow, turn the screw clockwise.

4. To check the low speed adjustment pull the throttle fully and the engine should not die, if it tries to die, open

the L screw slightly and re-adjust idle if necessary.

5. Set the engine to full throttle, the H adjusting screw is turned clockwise to reduce fuel, as the fuel mixture is

reduced, the engine will run faster until it sounds as if it is screaming, at this point, turn the H screw counter

clockwise by quarter (1/4) turn to allow more fuel.

A two stroke engine relies on the fuel mixture to cool the engine; a lean fuelled engine will run fast but

can

overheat and lead to engine seizure.

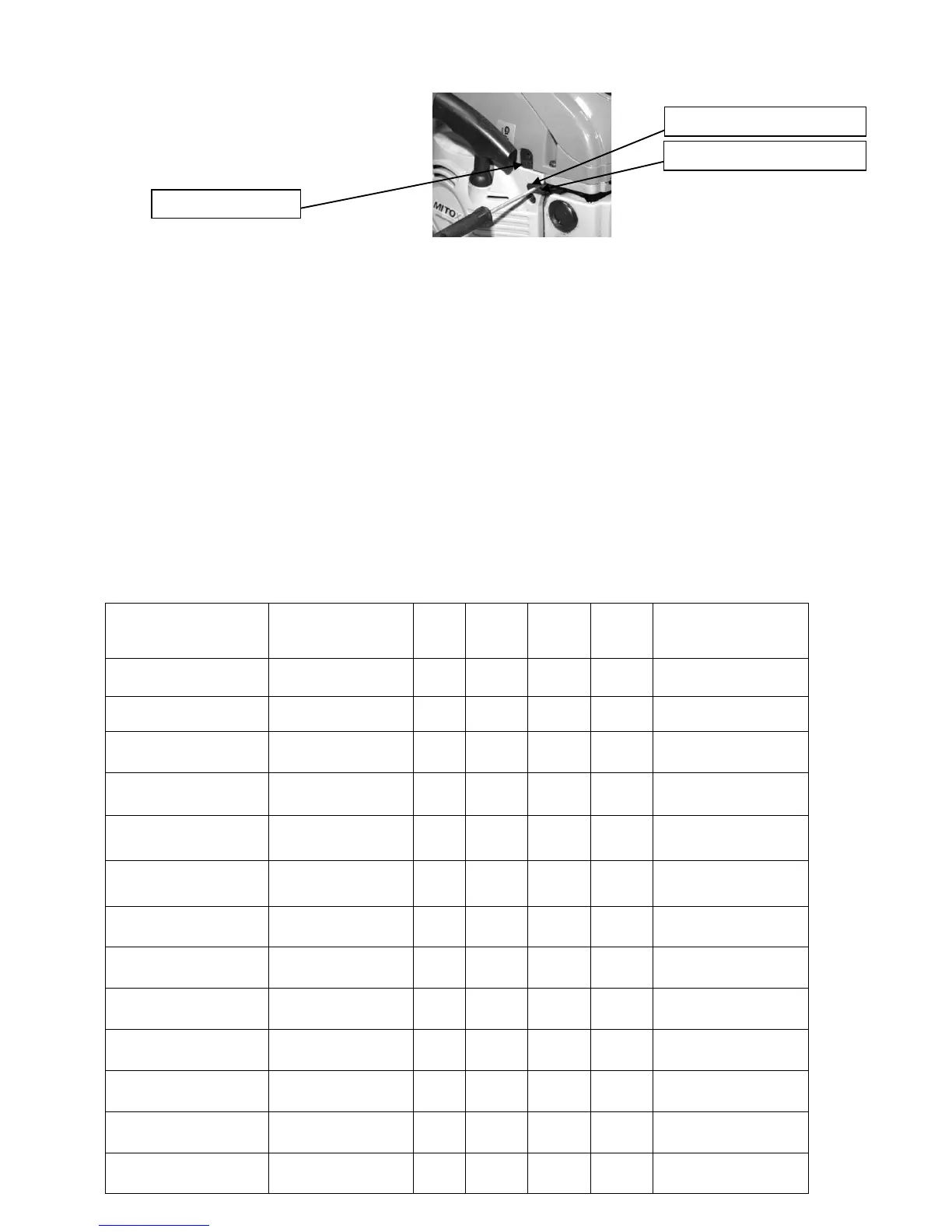

Component Procedure Before

use

Every

25

Hours

Loading...

Loading...