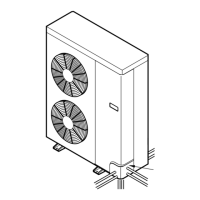

■Incaseofusing1-branchbox

Flareconnectionemployed(Nobrazing)

A

B

Liquid(mm) {9.52

Gas (mm) {15.88

Thepipeconnectionsizediffersaccordingtothetypeandcapacityofindoorunits.

Matchthepipingconnectionsizeofbranchboxwithindoorunit.

Ifthepipingconnectionsizeofbranchboxdoesnotmatchthepipingconnectionsize

ofindoorunit,useoptionaldifferent-diameter(deformed)jointstothebranchboxside.

(Connectdeformedjointdirectlytothebranchboxside.)

■Installationprocedure(2branchpipe(joint))

Refer to the installation manuals of

MSDD-50AR-E.

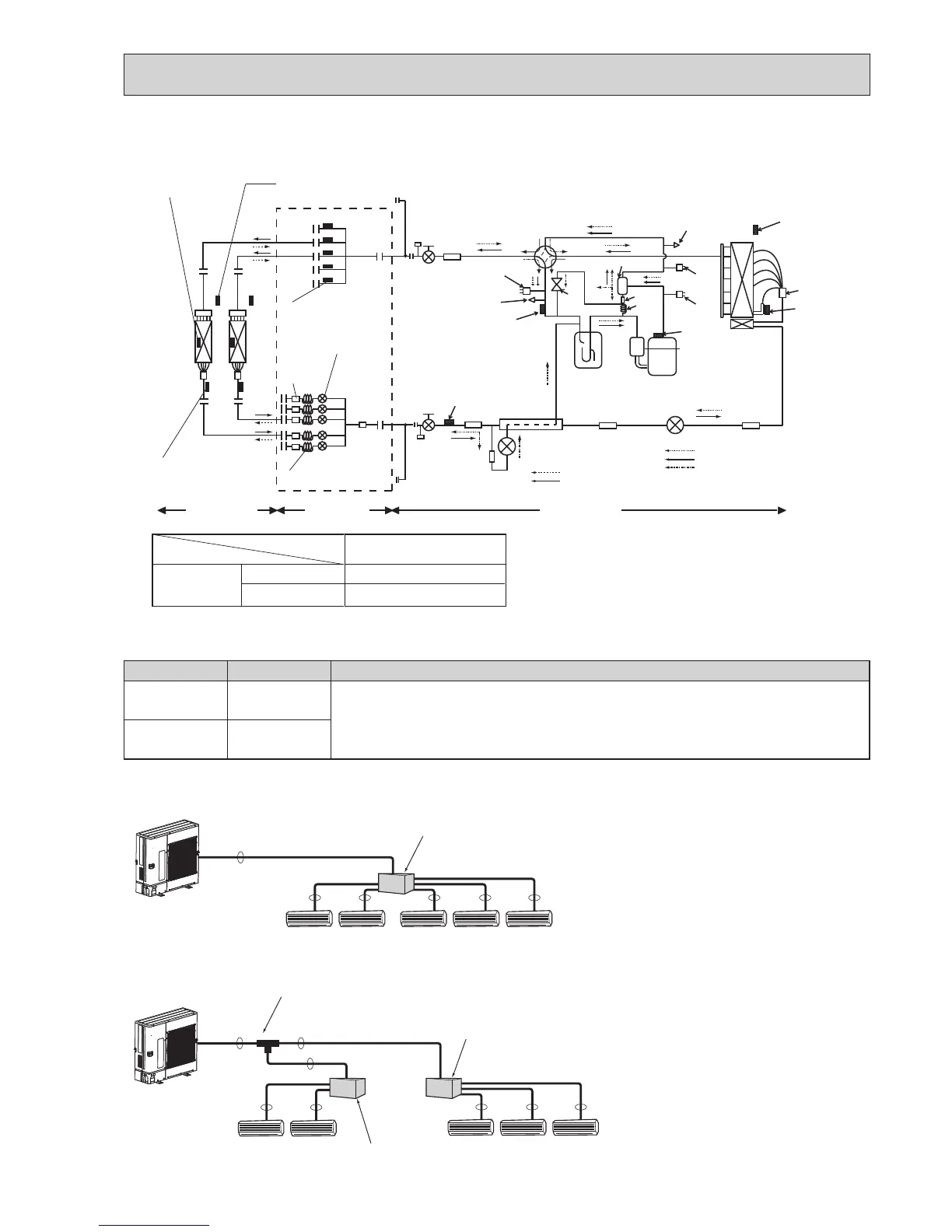

Capillary tube

E

D

C

B

A

Strainer

#100

Condenser / evaporator

temperature thermistor

(TH5 or RT12)

Pipe temperature

thermistor / liquid

(TH2 or RT13)

Strainer

#100

Indoor units Branch box Outdoor unit

Thermistor (TH-A–E)

(Gas pipe temperature)

LEV A–E

(Linear expansion valve)

Room temperature

thermistor (TH1 or RT11)

E

D

C

B

A

([4.0 o [3.0 o L130) o 5

PAC-MK31/33BC(B)

Branch box

Capillary tube behind LEV

(in cooling mode)

([4.0 o [3.0 o L130) o 3

Unit: mm

PAC-MK51/53BC(B)

Solenoid

valve

(SV1)

High pressure

sensor (63HS)

High pressure

switch (63H)

Low pressure

sensor(63LS)

Oil separator

Service port

Distributor

Compressor

Thermistor (TH4)

<

Compressor

>

Thermistor (TH7)

<Ambient>

<Outdoor liquid pipe>

Thermistor (TH3)

Ball valve

Strainer

4-way valve

Check valve

<Low pressure>

Thermistor (TH6)

<Suction pipe>

Check valve

<High pressure>

Strainer

Strainer

LEV-B

HIC

LEV-A

Strainer

Strainer

Thermistor (TH2)

<HIC pipe>

Stop valve

Service port

Capillary

tube

Accumulator

Strainer

Refrigerant flow in cooling

Refrigerant flow in heating

Refrigerant flow in cooling (Main)

Refrigerant flow in heating (Main)

Refrigerant flow in cooling (Sub)

Loading...

Loading...