What to do if my Mitsubishi Electric CMB-P1010 Air Conditioner pressure sensor reading doesn't change?

- PPhilip WoodsAug 7, 2025

If the pressure reading in the LD1 display does not change, the affected pressure sensor is faulty.

What to do if my Mitsubishi Electric CMB-P1010 Air Conditioner pressure sensor reading doesn't change?

If the pressure reading in the LD1 display does not change, the affected pressure sensor is faulty.

What to do if my Mitsubishi Electric CMB-P1010 Air Conditioner pressure is too high?

If the pressure is 3.14MPa (in the case of the low pressure sensor, 0.98MPa) or higher, the MAIN board is faulty.

What to do if my Mitsubishi Electric CMB-P1010 Air Conditioner pressure sensor shows 3.14MPa?

If the pressure according to the LD1 display is 3.14MPa (in the case of the low pressure sensor, 0.98MPa) or higher, the affected pressure sensor is faulty.

What to do if my Mitsubishi Electric Air Conditioner pressure is 0~0.098MPa?

If the pressure is 0~0.098MPa on the LD1 display, the affected pressure sensor is faulty.

Why is the internal pressure dropping in my Mitsubishi Electric CMB-P1010 Air Conditioner?

If the gauge pressure is 0~0.098MPa, it indicates the internal pressure is dropping due to gas leakage. Check for failure by comparing the sensing pressure.

What to do if my Mitsubishi Electric Air Conditioner pressure sensors differ by more than 0.098MPa?

If the difference between the two pressures exceeds 0.098MPa, the affected pressure sensor is faulty (deteriorating performance).

| Brand | Mitsubishi Electric |

|---|---|

| Model | CMB-P1010 |

| Category | Air Conditioner |

| Language | English |

Proper procedures for handling and storing refrigerant piping to prevent contamination and maintain quality.

Guidelines for airtightness, vacuuming, charging, and dryer replacement for R407C systems.

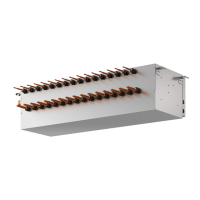

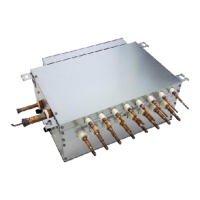

Visual identification of key parts in outdoor units for various models (PUHY, PUY, PURY).

Overview of Noise Filter Box, Terminal Box, Controller Box, and board connections.

Details on outdoor units, BC controllers, indoor units, piping kits, and remote controllers.

Diagrams illustrating refrigerant flow and sensor locations for PUHY, PUY, and PURY models.

Key operational parameters for cooling and heating modes across various models.

Explanation of DIP SW functions and settings for outdoor units.

Configuration details for indoor unit and BC controller DIP switches.

Essential checks from installation to system startup and operation.

Procedures for unit registration, retrieval, and deletion via remote control.

Operation of frequency, defrost, refrigerant, and BC controller functions.

Flowcharts detailing cooling, heating, dry, and BC controller operation logic.

Details on compressor, sensors, valves, and other critical components.

Procedures for adjusting and checking refrigerant levels in cooling and heating.

Diagnosis and repair steps for sensors, valves, motors, and boards.

Comprehensive list of error codes, their meanings, and countermeasures.

Steps for disassembling the BC controller's service panel and control box.

Procedures for checking and replacing thermistors, pressure sensors, LEVs, and solenoid valves.

Methods for locating and repairing refrigerant leaks in piping and units.

Procedure for verifying and calibrating refrigerant composition (αOC).

Loading...

Loading...