Do you have a question about the Mitsubishi Electric CMB-WP1016V-GA1 and is the answer not in the manual?

| Brand | Mitsubishi Electric |

|---|---|

| Model | CMB-WP1016V-GA1 |

| Category | Air Conditioner |

| Language | English |

Covers essential safety points for installation, operation, and handling, including specific hazards like refrigerant leaks and physical dangers.

Covers refrigerant type, installation, wiring, electrical work, and component safety measures.

Details piping materials, tool selection, and specific handling procedures for R410A refrigerant.

Covers proper grounding, power supply wire selection, and circuit protection devices.

Covers essential steps before starting a test run, including component checks and system readiness.

Covers essential pre-service checks, safety guidelines, and tool gathering.

Lists exclusive, restricted, prohibited, and compatible tools for R410A.

Details copper pipe materials, radial thickness, and types.

Outlines critical observations and explains the rationale behind brazing methods.

Details test procedures, nitrogen use, and leak detection considerations.

Specifies necessary equipment and evacuation duration.

Explains charging procedures and how to handle leaks.

Details oil types and the impact of contaminants on the refrigeration cycle.

Details compatible outdoor and indoor units for system setup.

Provides a comprehensive table for setting M-NET addresses for system components.

Step-by-step guide for setting component addresses.

Provides the detailed wiring schematic for the HBC and Sub-HBC.

Provides the wiring diagram for the transmission booster.

General diagram of the refrigerant system.

Specific refrigerant flow for the HBC controller.

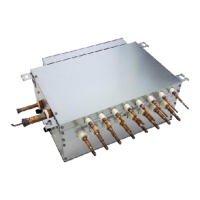

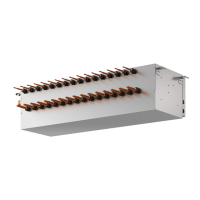

Describes major parts of the HBC controller and their functions.

Explains the functions and factory settings of dipswitches.

Details how to operate and control the HBC controller.

Explains the functions of SW3, SW4, and SW5 dipswitches.

Explains control logic for water pumps and valves.

Details control logic for heat exchangers and defrost operations.

Lists items to check before starting a test run.

Covers analyzing operating characteristics and adjusting refrigerant.

Lists all error codes with definitions and applicable units.

Guide to interpreting and resolving remote controller errors.

Details troubleshooting for drain, pump, and pressure sensor related errors.

Lists and explains error codes for temperature sensor failures.

Covers troubleshooting for ACCT, high-pressure sensor, and power supply errors.

Details troubleshooting for communication and signal sync issues.

Addresses causes and remedies for drain sensor submergence errors.

Addresses causes and remedies for drain pump faults related to float switches.

Details causes and remedies for water pump malfunctions.

Addresses causes and remedies for sensor-related drain pump faults.

Addresses causes and remedies for float switch related drain pump faults.

Details causes and remedies for drain sensor thermistor faults.

Procedures for finding leaks in extension pipes, HBC controllers, and outdoor units during cooling.

Procedures for finding leaks in extension pipes, HBC controllers, and outdoor units during heating.

Explains how to interpret LED displays on the service monitor.

Explains how to read LEDs on the HBC/Sub-HBC boards.

Explains how to read outdoor unit board LEDs.