Do you have a question about the Mitsubishi Electric FR-E720-0.1KNC and is the answer not in the manual?

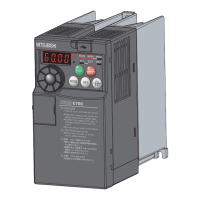

Procedure for verifying the inverter contents and identifying its parts for proper setup and operation.

Overview of essential peripheral devices that connect with the inverter for system functionality.

Instructions for safely removing and reattaching the inverter's front and wiring covers.

Guidelines for selecting an appropriate installation environment and enclosure design for the inverter.

Explanation of fundamental wiring practices and terminal connection diagrams for the inverter.

Details on main circuit terminal layout, specifications, and recommended cable sizes for power and motor connections.

Information on control circuit terminals, input/output signals, and communication interfaces like CC-Link and USB.

Instructions for connecting external option units such as brake resistors and DC reactors to the inverter.

Guidelines for managing electromagnetic compatibility and reducing leakage currents to prevent malfunctions.

Recommendations for installing power factor improving reactors to prevent excessive peak currents in the input circuit.

Guidelines for using magnetic contactors on the inverter's input side for safety and maintenance.

Measures to address surge voltage and insulation deterioration when driving 400V class motors with the inverter.

Key safety and operational guidelines to ensure product longevity and prevent damage or incorrect handling.

Strategies for detecting inverter failures and implementing system safeguards to prevent accidents.

Details on communication interface specifications, compatibility, and system configuration requirements for CC-Link.

Information on compatibility between CC-Link Ver. 1.10 and Ver. 2, including master station requirements.

Guidelines for system configuration, cabling, and connecting multiple inverters using CC-Link communication.

Explanation of data transfer, function blocks, and communication start commands for CC-Link operation.

Comprehensive list of I/O signals and remote registers used for CC-Link communication with the inverter.

Detailed explanations of remote I/O signals and remote registers for CC-Link communication configuration.

Practical examples demonstrating programming for reading inverter status, setting parameters, and monitoring via CC-Link.

Guide to diagnosing CC-Link communication errors by interpreting the status of the inverter's LEDs.

Detailed description of the operation panel buttons, indicators, and their functions for inverter setup.

Comprehensive list of all inverter parameters, their settings, instruction codes, and control mode correspondences.

Guide to selecting the inverter's operation mode, such as PU or Network operation, for controlling start and frequency commands.

Instructions for configuring CC-Link communication, including station numbers, baud rates, and error handling.

Explanation of available control modes like V/F, Advanced Magnetic Flux Vector, and General-purpose Magnetic Flux Vector control.

Methods for adjusting motor torque, including manual torque boost, automatic current control, and stall prevention.

How to set upper and lower output frequency limits and avoid mechanical resonance points using frequency jumps.

Guidance on setting base frequency, voltage, and load patterns for optimal V/F characteristic matching.

Instructions for setting frequency using multi-speed operations and remote setting functions via input signals.

Configuration of acceleration/deceleration times, reference frequencies, and patterns like linear and S-pattern.

Guidance on selecting appropriate motors, motor overheat protection, and auto-tuning procedures for optimal performance.

Details on DC injection braking, regenerative braking selection, and various motor stopping methods.

How to assign functions to external terminals and CC-Link virtual terminals for input and output signals.

Configuration for displaying motor speed, operation panel parameters, and monitoring output signals.

Settings for automatic restart after power failures and power-failure deceleration stop functions to ensure continuous operation.

Procedures for handling faults, including retry functions, phase loss protection, and earth fault detection.

Information on implementing energy-saving features like optimum excitation control for fan and pump applications.

Techniques to reduce motor noise, EMI interference, and mechanical resonance using PWM carrier frequency and speed smoothing.

Methods to prevent misoperations, such as reset selection, parameter write protection, and password functions.

Advanced control features including JOG operation, PID control, droop control, and regeneration avoidance.

Utilization of features like cooling fan control, inverter part life display, maintenance timers, and USB communication.

How to configure settings directly from the inverter's operation panel, including rotation direction and key lock.

Procedures for clearing specific parameters or resetting all parameters to their initial values.

Functionality for managing and viewing changes made to initial parameter values.

How to access, view, and clear the inverter's fault history for troubleshooting.

Procedures for resetting inverter faults and protective functions after corrective actions.

A comprehensive list of all possible fault and alarm indications displayed by the inverter.

Detailed explanations of common causes for inverter faults and their corresponding corrective actions.

Mapping between digital character codes and their actual alphanumeric representations on the operation panel.

Essential checks to perform first when encountering issues like motor not starting or incorrect speed.

Daily and periodic inspection checklists, including environmental checks, component integrity, and cooling system.

Guidelines and methods for measuring main circuit voltages, currents, and powers using appropriate instruments.

Detailed electrical ratings, applicable motor capacities, and power supply specifications for various inverter models.

General specifications applicable to the inverter series, covering control methods, I/O, protective functions, and environmental conditions.

Physical dimensions and mounting information for different FR-E700 inverter models.

| Brand | Mitsubishi Electric |

|---|---|

| Model | FR-E720-0.1KNC |

| Category | Inverter |

| Language | English |

Loading...

Loading...