19

4.5 Connecting inputs/outputs

For multiple outdoor units control with FTC (Sub), see section 9.

en

4. Electrical work

Signal inputs

Item Name Model and specications

Signal input

function

Signal input

wire

Use sheathed vinyl coated cord or cable: 30 m max.

Wire type: CV, CVS or equivalent

Wire size: Stranded wire 0.13 mm² to 0.52 mm²

Solid wire: ø0.4 mm to ø0.8 mm

Switch Non-voltage “a” contact signals

Remote switch: minimum applicable load 12 V DC, 1 mA

Wiring specication and local supply parts

Name

Terminal

block

Con-

nector

Item OFF (Open) ON (Short)

IN1 TBI.1 7-8 —

Room thermostat 1 input *1

Refer to SW2-1 in <5.1 DIP switch functions>.

IN2 TBI.1 5-6 —

Flow switch 1 input

Refer to SW2-2 in <5.1 DIP switch functions>.

IN3 TBI.1 3-4 —

Flow switch 2 input (Zone 1)

Refer to SW3-2 in <5.1 DIP switch functions>.

IN4 TBI.1 1-2 —

Demand control input

Normal

Heat source OFF/ Boiler operation *3

IN5 TBI.2 7-8 —

Outdoor thermostat input *2 Standard operation Heater operation/ Boiler operation *3

IN6 TBI.2 5-6 —

Room thermostat 2 input *1

Refer to SW3-1 in <5.1 DIP switch functions>.

IN7 TBI.2 3-4 —

Flow switch 3 input (Zone 2)

Refer to SW3-2 in <5.1 DIP switch functions>.

IN8 TBI.3 7-8 —

Electric energy meter 1

*4IN9 TBI.3 5-6 —

Electric energy meter 2

IN10 TBI.2 1-2 —

Heat meter

IN11 TBI.3 3-4 —

Smart grid ready input

*5

IN12 TBI.3 1-2 —

IN13 TBI.4 3-4 — Forced cooling mode Refer to SW7-2 in <5.1 DIP switch functions>.

IN15 TBI.4 1-2 — Cooling limit temp. Refer to SW7-3 in <5.1 DIP switch functions>.

INA1 TBI.6 3-5 CN1A

Flow sensor input

*6

*1. Set the ON/OFF cycle time of the room thermostat for 10 minutes or more; otherwise the compressor may be

damaged.

*2. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may

be reduced.

*3. To turn on the boiler operation, use the main remote controller to select [Boiler settings] in [Operation settings]

from [Service].

*4. Connectable electric energy meter and heat meter

● Pulse type Voltage free contact for 12 VDC detection by FTC

(TBI.2 1 pin, TBI.3 5 and 7 pins have a positive voltage.)

● Pulse duration Minimum ON time: 40ms

Minimum OFF time: 100ms

● Possible unit of pulse 0.1 pulse/kWh 1 pulse/kWh 10 pulse/kWh

100 pulse/kWh 1000 pulse/kWh

Those values can be set by the main remote controller. (Refer to the menu tree in "7.2 Main remote controller".)

*5. As for the smart grid ready, refer to "4.9 Smart grid ready".

*6. Connectable ow sensor

● Power supply 5 V DC

● Measuring range 5 to 100 L/min

Those values can be set by the main remote controller. (Refer to [Auxiliary settings] on this page.)

● Flow signal 0.5 V (at minimum ow rate) to 3.5 V (at maximum ow rate)

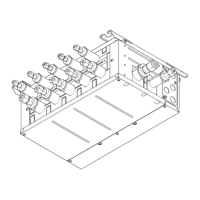

<Fig. 4.5.1>

[Auxiliary settings]

This function is used to set the parameters for any auxiliary parts used in the system

Menu subtitle Function/ Description

[Economy settings for pump] Water pump stops automatically in certain period of time from when operation is nished.

[Delay] Time before pump switched o*1

[Electric heater (Heating)] To select “WITH booster heater (ON)” or “WITHOUT booster heater (OFF)” in heating mode.

[Delay] The minimum time required for the booster heater to turn ON from after heating mode has started.

[Electric heater (DHW)] To select "WITH (ON)" or "WITHOUT (OFF)" booster heater or immersion heater individually in DHW mode.

[Delay] The minimum time required for the booster heater or immersion heater to turn ON from after DHW mode has started.

(This setting is applied for both booster and immersion heater.)

Mixing valve 1/2 control

*2

[Running] Period from valve fully open (at a hot water mixing ratio of 100%) to valve fully closed (at a cold water mixing ratio of 100%)

[Interval] Interval (min.) to control the mixing valve.

[Flow sensor] *3 [Minimum] The minimum ow rate to be detected at ow sensor.

[Maximum] The maximum ow rate to be detected at ow sensor.

*1. Decreasing "time before pump switched o" may increase the duration of stand-by in heating/cooling mode.

*2. Set the running time according to the specications of the actuator of each mixing valve. It is recommended to set the interval to 2 minutes that is a default value.

With the interval set longer, it could take longer to warm up a room.

*3. Do not change the setting since it is set according to the specication of ow sensor attached to the indoor unit.

Note:

Stranded wire should be processed with insulation-covered bar terminal

(DIN46228-4 standard compatible type).

Loading...

Loading...