SERVICE MANUAL

• This manual describes only

service data of the indoor

units.

[Model names]

PEA-RP200GA

PEA-RP250GA

PEA-RP400GA

PEA-RP500GA

CONTENTS

1.

TYPES OF CONNECTED OUTDOOR UNITS

····2

2. SAFETY PRECAUTION ···································3

3. PART NAMES AND FUNCTIONS····················8

4. SPECIFICATIONS ··········································10

5. DATA·······························································11

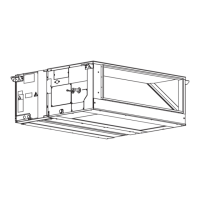

6. OUTLINES AND DIMENSIONS ·····················13

7. WIRING DIAGRAM ·········································16

8. REFRIGERANT SYSTEM DIAGRAM ············18

9. TROUBLESHOOTING ····································19

10. SERVICE DATA (PARTS NAME) ···················30

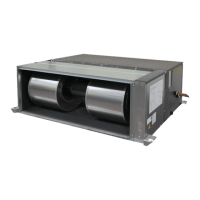

Indoor unit

Remote controller