Do you have a question about the Mitsubishi Heavy Industries S4S and is the answer not in the manual?

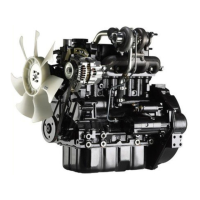

| Engine Model | S4S |

|---|---|

| Category | Engine |

| Manufacturer | Mitsubishi Heavy Industries |

| Cylinders | 4 |

| Aspiration | Naturally Aspirated |

| Fuel System | Direct Injection |

| Fuel Type | Diesel |

| Displacement | 3.331 L |

| Fuel | Diesel |

| Type | 4-cycle, water-cooled diesel engine |

Guidance on navigating and utilizing the service manual effectively.

Essential safety guidelines covering fire, electrical, thermal, mechanical, and operational hazards.

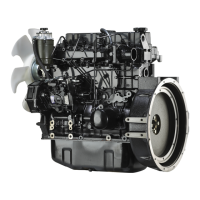

Diagrams illustrating engine component locations and external views.

Visual representations of fuel, lubrication, cooling, and exhaust systems.

Key technical parameters and data for engine models S4S and S4S-DT.

Recommended procedures and basic safety advice for engine service tasks.

Specifications and tolerance limits for engine component inspection and maintenance.

Torque values for various engine bolts and nuts to ensure proper assembly.

Identification and usage of specialized tools required for engine maintenance and repair.

Guidelines for assessing when an engine requires a complete overhaul based on symptoms.

Procedure and standards for measuring engine cylinder compression pressure.

Steps for removing and inspecting cylinder head and valve train components.

Procedures for removing and inspecting the engine flywheel.

Steps for disassembling and inspecting timing gears and camshaft assembly.

Procedures for dismantling major internal engine components.

Methods for inspecting and repairing cylinder head and valve components.

Procedures for inspecting and repairing the engine flywheel.

Methods for inspecting and repairing timing gears and camshaft.

Inspection and repair procedures for key engine rotating and stationary parts.

Steps for reassembling the engine's bottom end components.

Procedures for reinstalling timing gears and camshaft assembly.

Steps for installing the engine flywheel.

Procedures for reinstalling the cylinder head and valve train.

Steps for safely removing fuel system parts like filters and pipes.

Detailed procedures for servicing fuel system components, including nozzles.

Steps for correctly installing fuel system parts after service.

Procedures for removing oil filter, oil cooler, oil pump, and oil pan.

Detailed steps for servicing the oil pump, oil cooler, and oil filter.

Procedures for reinstalling lubrication system parts.

Steps for removing fan, thermostat, and water pump.

Detailed procedures for servicing the thermostat and water pump.

Steps for reinstalling cooling system parts like water pump and fan.

Steps for removing turbocharger, inlet, and exhaust manifolds.

Procedures for inspecting and repairing exhaust manifold distortion.

Steps for reinstalling turbocharger, inlet, and exhaust manifolds.

Steps for removing starter, alternator, and glow plugs.

Detailed procedures for servicing starter and alternator components.

Steps for reinstalling starter, alternator, and glow plugs.

Instructions for adjusting valve clearance and V-belt tension.

Procedures and timeframes for engine break-in after overhaul or installation.

Methods for conducting engine performance tests and output adjustments.