8. Lower the vehicle slowly by rotating the

wheel nut wrench anticlockwise until the

tyre touches the ground.

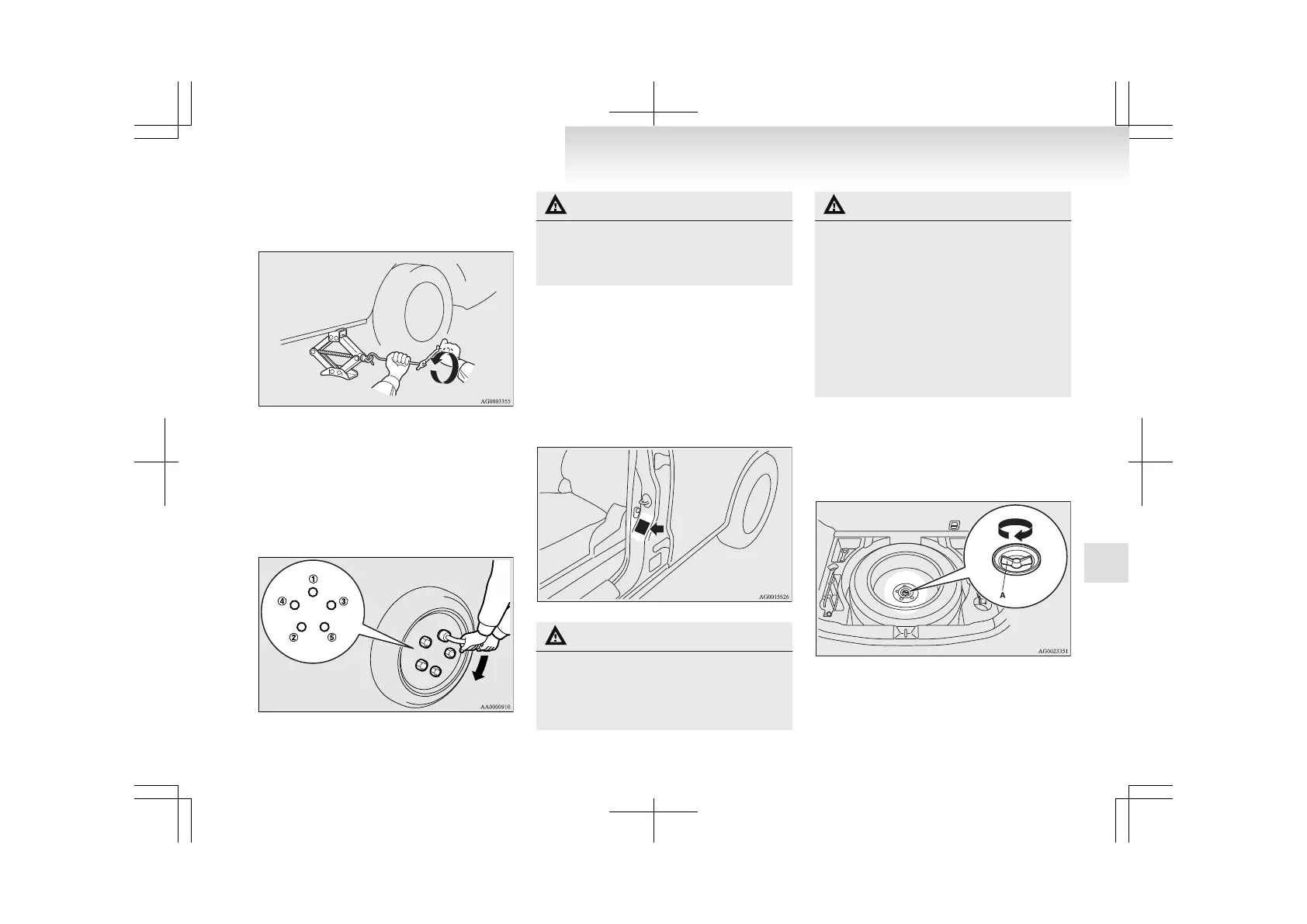

9. Tighten

the nuts in the order shown in the il-

lustration until each nut has been tightened

to the torque listed here.

Tightening torque 88 to 108 Nm

(Achieved by applying force of 350 to 420 N

at end of wheel nut wrench supplied with ve-

hicle)

CAUTION

l

Never use your foot or a pipe extension

for extra force in the wheel nut wrench.

If you do so, you will tighten the nut too

much.

10. If the vehicle has a wheel cover, install it.

Refer to “Wheel covers” on page

6-18.

11. Lower and remove the jack, then store the

jack, flat tyre, and chocks. Have your dam-

aged tyre repaired as soon as possible.

12. Check your tyre inflation pressure at the next

gasstation.

The correct tyre pressures are shown on the

driver’s door label. See the illustration.

CAUTION

l

The

temporary spare wheel is to be used

only temporarily when the standard

wheel is damaged. Repair the damaged

tyre as soon as possible and use it to re-

place the temporary spare tyre.

CAUTION

l

After changing the tyre and driving the ve-

hicle about 1,000 km (620 miles), retight-

en the wheel nuts to make sure that they

have not come loose.

l

If the steering wheel vibrates when driv-

ing after changing the tyre, we recom-

mend you to have the tyres checked for

balance.

l

Do not mix one type of tyre with another

or use a different size from the one listed.

This would cause early wear and poor han-

dling.

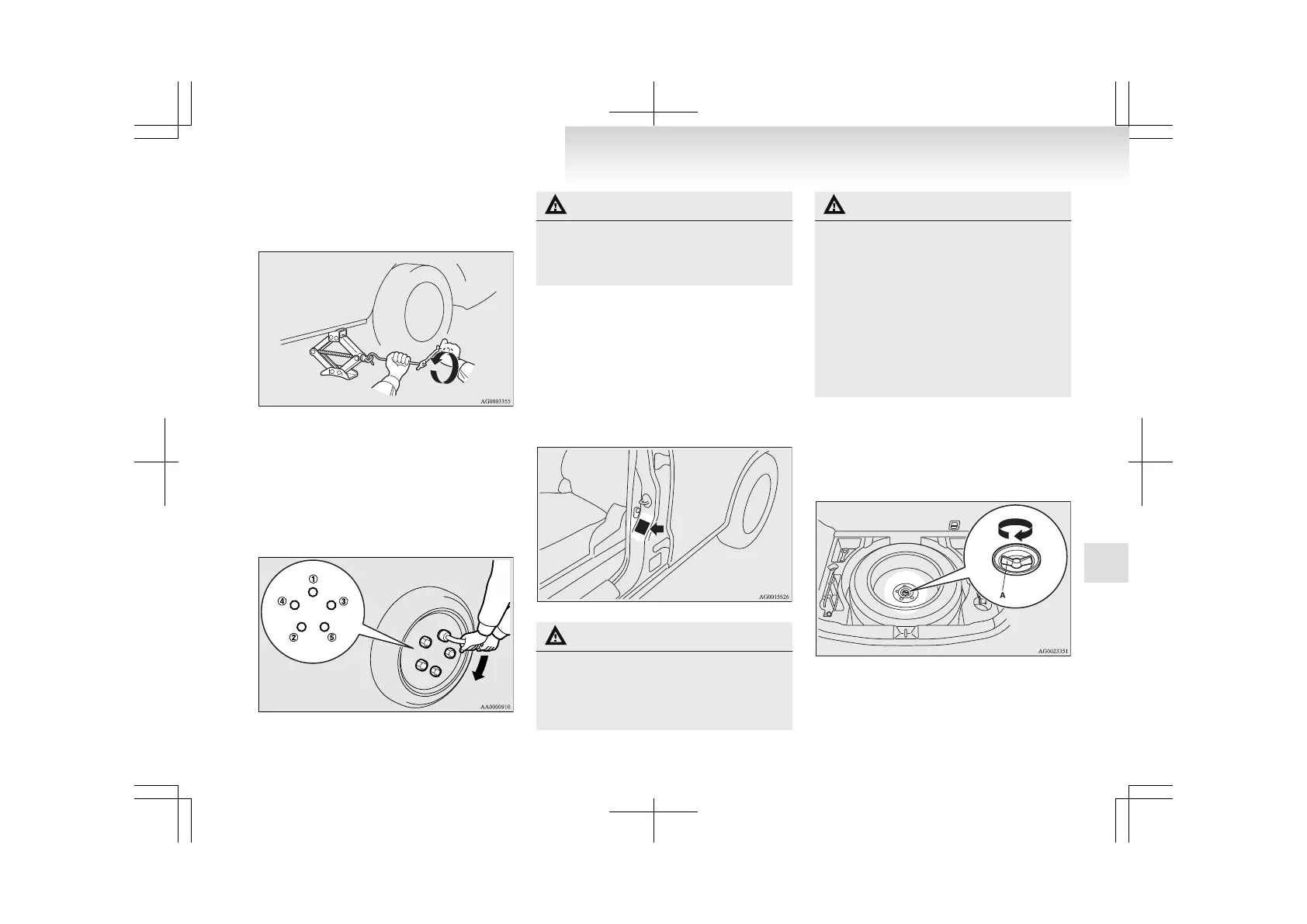

To store the flat tyre or spare wheel

E00803400176

1. Lift up the luggage floor board.

2. To

store the flat tyre or spare wheel, fit the

installation clamp (A) by turning it clockwise.

NOTE

l

On

vehicles with a T155/90D16 or

T125/90D16 size spare wheel, the clamp can-

not be used for a normal size tyre.

For emergencies

6-17

6

Loading...

Loading...