12 - 71

MELSEC-Q

12 CONTROL SUB FUNCTIONS

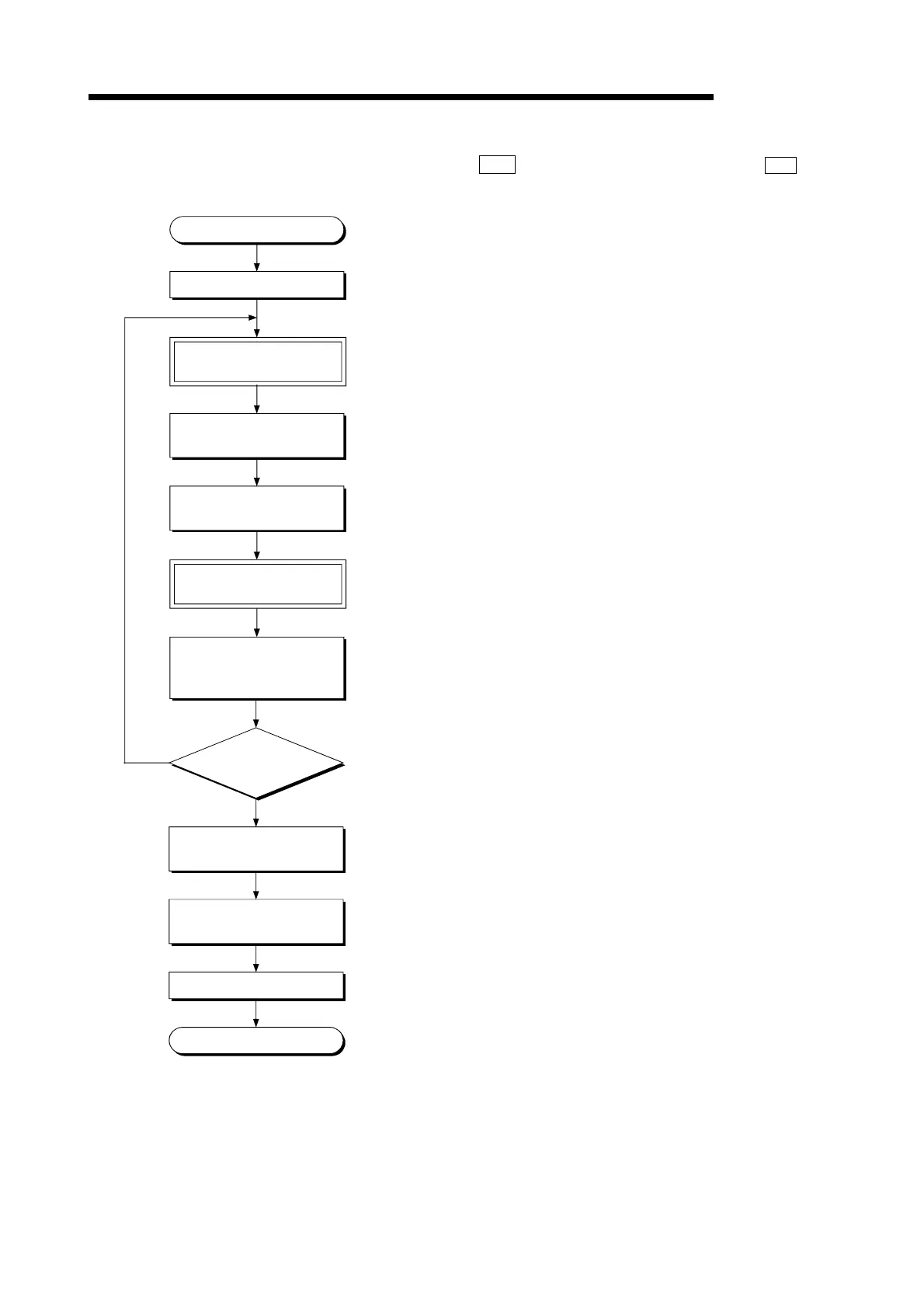

(2) When teaching to the "

Da.7

Arc address", then teaching to the "

Da.6

Positioning address/movement amount"

Start

Carry out a machine OPR.

Using a JOG operation, inching operation, or manual pulse generator.

Move the workpiece to the circular

interpolation sub point using a

manual operation.

Set the positioning data No. for

which the teaching will be carried out.

Move the workpiece to the circular

interpolation end point position

using a manual operation.

Set the current feed value in the

arc sub point by teaching

data selection.

Set the positioning data No. in the buffer memory address [1549].

Set 1 in the buffer memory address [1548].

Set the current feed value in the

positioning address by teaching

data selection.

Using a JOG operation, inching operation, or manual pulse generator.

Set 0 in the buffer memory address [1548].

• • • • • • • •

• • • • • • • •

• • • • • • • •

• • • • • • • •

• • • • • • • •

NO

YES

End

Confirm the completion of the writing.

Turn OFF the PLC READY

signal [Y0].

Carry out a writing request to

the flash ROM.

End teaching?

Confirm that the buffer memory address [1900] has become 0.

Set 1 in the buffer memory address [1900].

• • • • • • • •

• • • • • • • •

Loading...

Loading...