Chapter 3 OPERATION

3-13

Operation

Do not approach rotating parts while in opera-

tion. Entanglement by rotating parts can cause

serious injury.

Do not touch any part of the engine while it is oper-

ating or immediately after it is shut down. A hot

engine can cause burns.

Provide adequate ventilation in the engine room. If

air supplied to the engine room is restricted, the

room temperature increases and can affect engine

output and performance.

During the first 50 hours of operation, break-in the

engine by operating it with light load and at lower

speed than normal.

Operating the engine under high load or severe

conditions during the break-in period can shorten

the service life of the engine.

After the warm-up operation, start operating the

engine with load.

Inspection During Operation

Check for leakages.

Inspect the exterior of the engine to make sure

there is no leakage from joints.

Check to make sure the engine does not produce

abnormal noise or vibrations.

Inspect the engine for abnormal operating sound

and vibrations such as knocking.

Check to make sure the exhaust gas is normal

color.

Check the color of the exhaust gas discharged from

the exhaust pipe.

Note: Regarding abnormal exhaust gas conditions,

refer to "Engine Produces Large Amount of

Smoke While in Operation" (9-8).

Check to make sure that the mist discharged from

the breather is not abnormal in the amount or color.

Check to make sure the instruments and gages

indicate normal values.

Note:(a) When the oil pressure drops below 0.29

MPa (3 kgf/cm

2

) [42.7 psi] in normal oper-

ation, or below 0.10 MPa (1 kgf/cm

2

) [14.2

psi] at minimum speed with no load, stop

the engine immediately. Before restarting

the engine, check and correct the cause of

the problem.

(b) When the high temperature alarm switch

is activated in normal operation, change

the engine operation immediately to no-

load idling condition until the engine tem-

perature decreases to normal operating

level. Then, operate the engine for

another 5 or 6 minutes for cooling before

stopping the engine.

Before restarting the engine, check and

correct the cause of the problem.

If the above inspection finds an abnormality, stop

the engine immediately, correct all problems, and

restart the engine. If the engine cannot be repaired,

contact a Mitsubishi dealer.

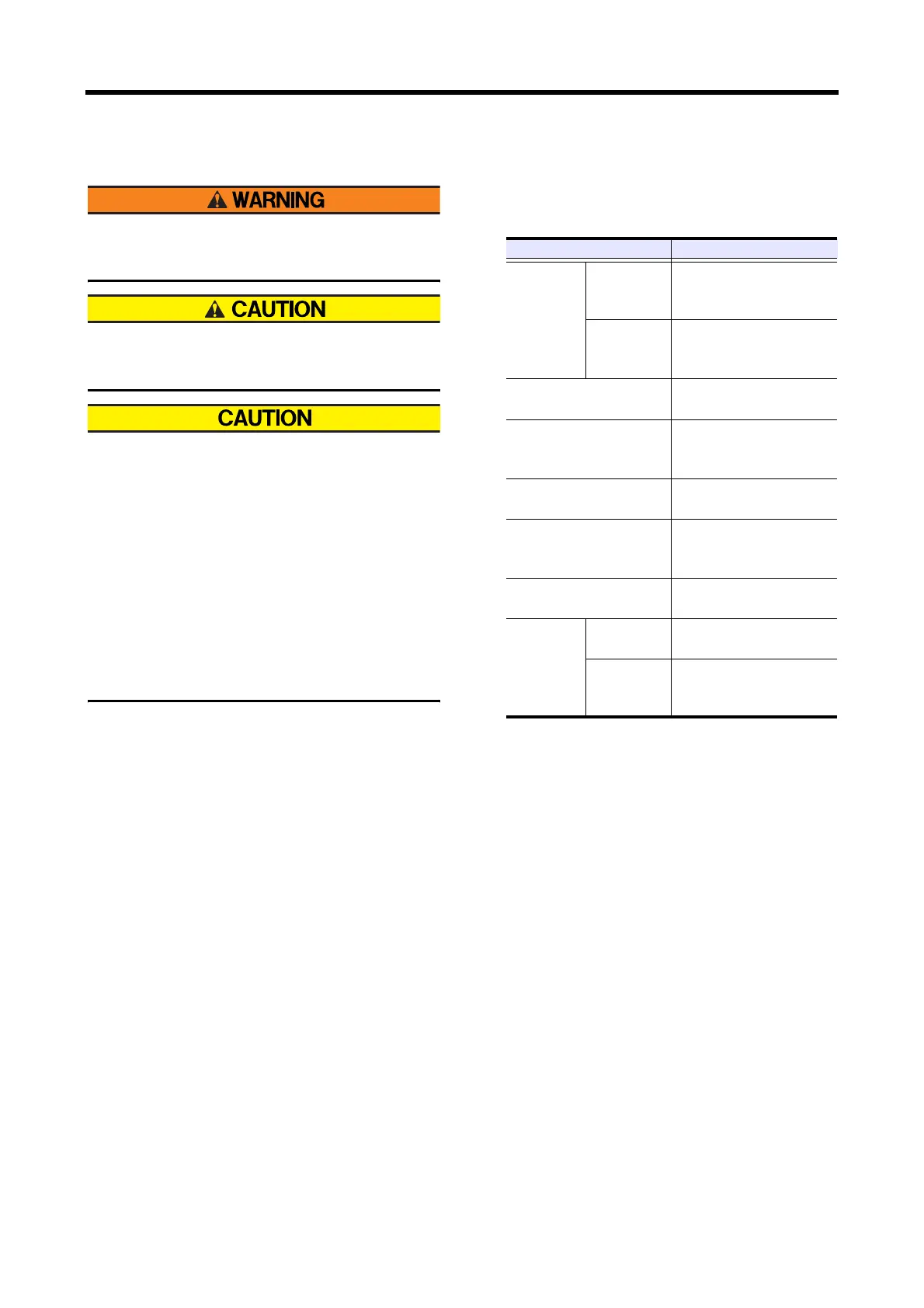

Table 3-2 Data for rated speed

Item Standard value

Engine oil

pressure

No load,

low idling

speed

0.20 to 0.39 MPa

(2.0 to 4.0 kgf/cm

2

)

[29 to 56.56 psi]

Rated

speed

0.39 to0.69 MPa

(4.0 to 7.0 kgf/cm

2

)

[56.56 to 100.08 psi]

Engine oil

temperature

70 to 100 °C

[158 to 212 °F]

Jacket coolant

pressure

0.05 to 0.34 MPa

(0.5 to 3.5 kgf/cm

2

)

[7.25 to 49.31 psi]

Jacket coolant

temperature

65 to 85 °C

[149 to 185 °F]

Oil cooler/air cooler

coolant pressure

0.05 to 0.34 MPa

(0.5 to 3.5 kgf/cm

2

)

[7.25 to 49.31 psi]

Oil cooler/air cooler

coolant temperature

30 to 85 °C

[86 to 185 °F]

Exhaust

tempera-

ture

Cylinder

outlets

250 to 650 °C

[482 to 1202 °F]

Turbo-

charger

outlet

250 to 600 °C

[482 to 1112 °F]

Loading...

Loading...