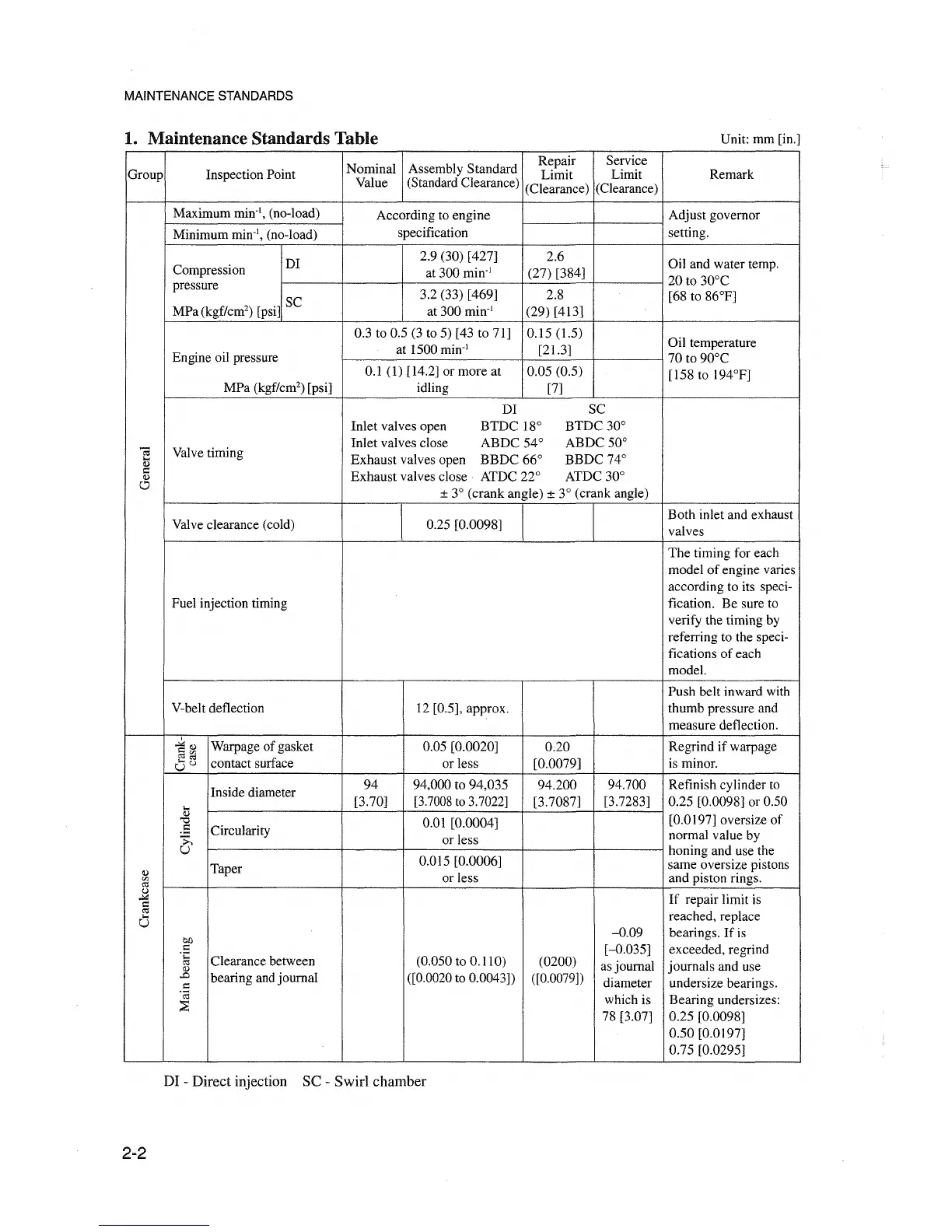

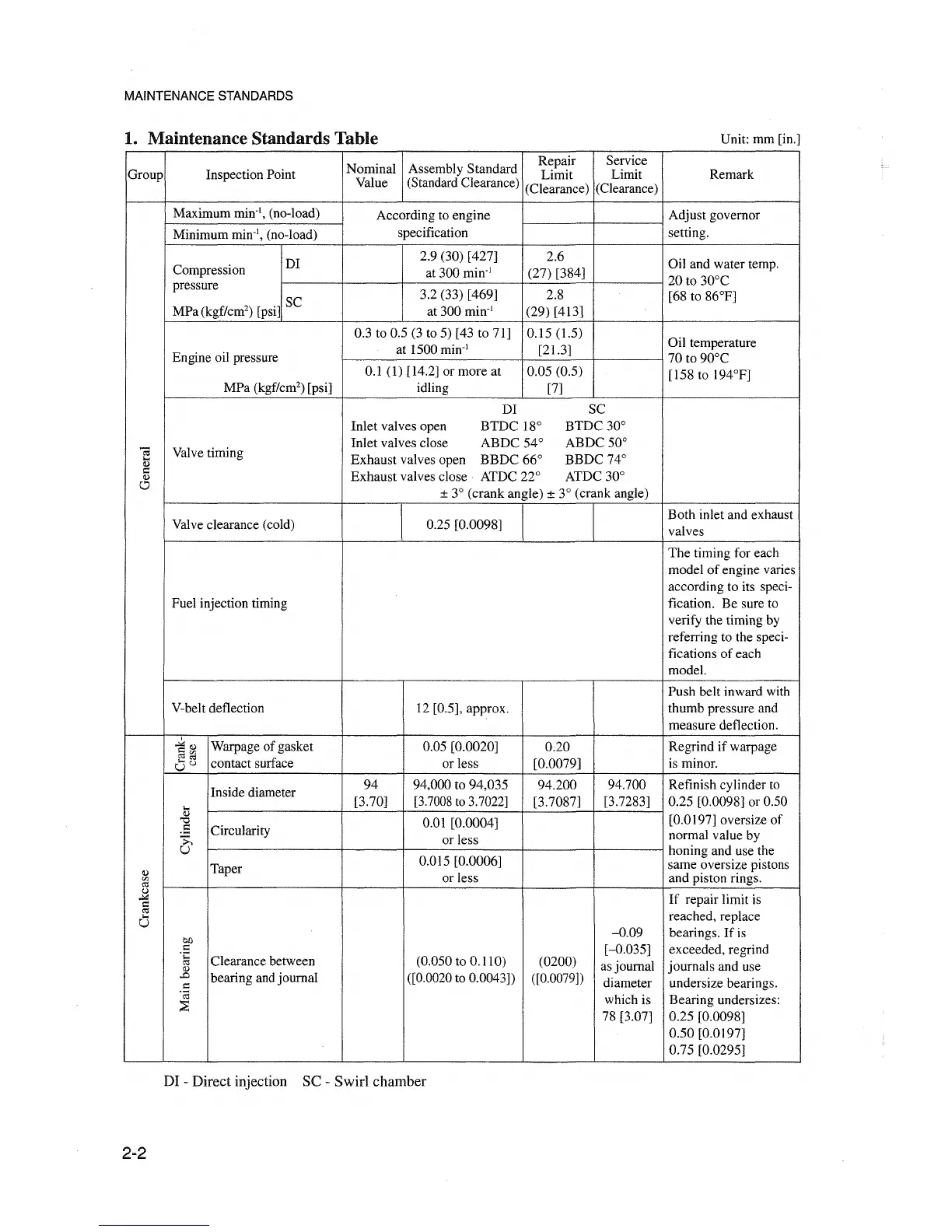

MAINTENANCE STANDARDS

1. Maintenance Standards Table

Unit: mm [in.]

Nominal

Assembly

Standard

Repair

Service

Group Inspeetion Point

Limit

Limit Remark

Value (Standard Clearance)

(Clearance)

(Clearance)

Maximum min-I, (no-load)

According to engine

Adjust governor

Minimum min", (no-lead)

specification setting.

DI

2.9 (30) [427]

2.6

Oil and water temp.

Compression

at 300 min:'

(27) [384]

20 to

30°C

pressure

3.2 (33) [469]

2.8

[68 to 86°F]

Ml'atkgf/cm') [psi]

SC

at 300 min-I

(29)

[413]

0.3 to 0.5 (3 to 5) [43 to 71] 0.15 (1.5)

üil

temperature

Engine oil pressure

at 1500 min:'

[21.3]

70 to 90°C

0.1

(1) [14.2] or

more

at

0.05

(0.5)

[158 to 194°F]

MPa (kgf/cm") [psi] idling [7]

DI SC

Inlet

valves open

BTDC

18°

BTDC

30°

C;

Valve timing

Inlet

valves close

ABDC

54°

ABDC

50°

....

Exhaust

valves open

BBDC

66°

BBDC

74°

(1)

c

Exhaust

valves close

ATDC

22°

ATDC 30°

(1)

c

± 3°

(crank

angle) ± 3° (crank angle)

Valve clearance (cold)

Both

in1et and exhaust

0.25 [0.0098]

valves

The

timing for each

model

of

engine varies

according to its speci-

Fuel injection timing fication. Be sure to

verify the timing by

referring to the speci-

fications

of

each

model.

Push beIt inward with

V-belt deflection 12 [0.5], approx.

thumb

pressure and

measure

deflection.

,

"""'(1)

Warpage of gasket 0.05 [0.0020]

0.20

Regrind

if

warpage

<=:",

~~

contact surface

or 1ess [0.0079]

is minor.

Uu

Inside diameter

94

94,000 to 94,035

94.200 94.700 Refinish cylinder to

...

[3.70] [3.7008to 3.7022]

[3.7087]

[3.7283] 0.25 [0.0098] or 0.50

(1)

[0.0197] oversize of

"0

0.01 [0.0004]

.5

Circularity

>..

or less

normal value by

U

honing and use the

Taper

0.015 [0.0006]

same

oversize pistons

(1)

or less

and piston rings.

'"

<:Il

u

~

If repair limit is

<=:

<:Il

reached, replace

...

U

-0.09

bearings.

If

is

01)

<=:

[-0.035] exceeded, regrind

.t:

Clearance between

(0.050 to 0.110)

~

(0200)

asjoumal

journals

and

use(1)

.D

bearing and journal ([0.0020 to 0.0043]) ([0.0079])

diameter undersize bearings.

<=:

'ca

which is Bearing undersizes:

::E

78 [3.07]

0.25 [0.0098]

0.50

[0.0197]

0.75 [0.0295]

DI - Direct injection SC - Swirl chamber

2-2

Loading...

Loading...