(8) During transportation, look at the display from

time to time to see if it keeps and established

storage temperature.

12.3 Monthly inspection

(1) Check the belt for looseness, degree of parallel

(stick-out of interline) and scraches. (bending of

the belt is to be about 7mm ~ 10mm.)

(2) Check if anything is touching to another part.

(compressor, pulley, belt, tubing and wiring)

(3) Clean carefully the refrigeration unit and drain

pipe with soft brush.

The fins will be deformed or damaged if a hard

brush is used.

Note:

(a) Never make a high pressure washing with a

high pressure washing machine as it crushes

its fin.

(b) Never make a steam washing as it raises its

inside pressure unusually high and is

dangerous.

(4) Check the refrigerant sight glass for color and

degree of flash.

Green = Normal

Yellow = Abnormal (water in it)

Lots of bubbles = Insufficient refrigerant

(Replacement of dryer and refrigerant is needed if

water is in it)

(5) Check refrigeration. (Check temperature indication

on the display and high and low pressure power.)

As to high and low pressure power, refer to page

41.

(6) Implement the matters to be taken care of at the

time of periodic inspection as shown on page 38.

12.4 Six-mouth inspection

(1) Implement the checking items required at the time

of installation-test operation and monthly

checking. (excluding a check for mis-wiring)

(2) Check the relay for contact point.

Correct defective contact point due to short circuit.

(3) Carry out the warning items at the time of periodic

inspection listed on page 38.

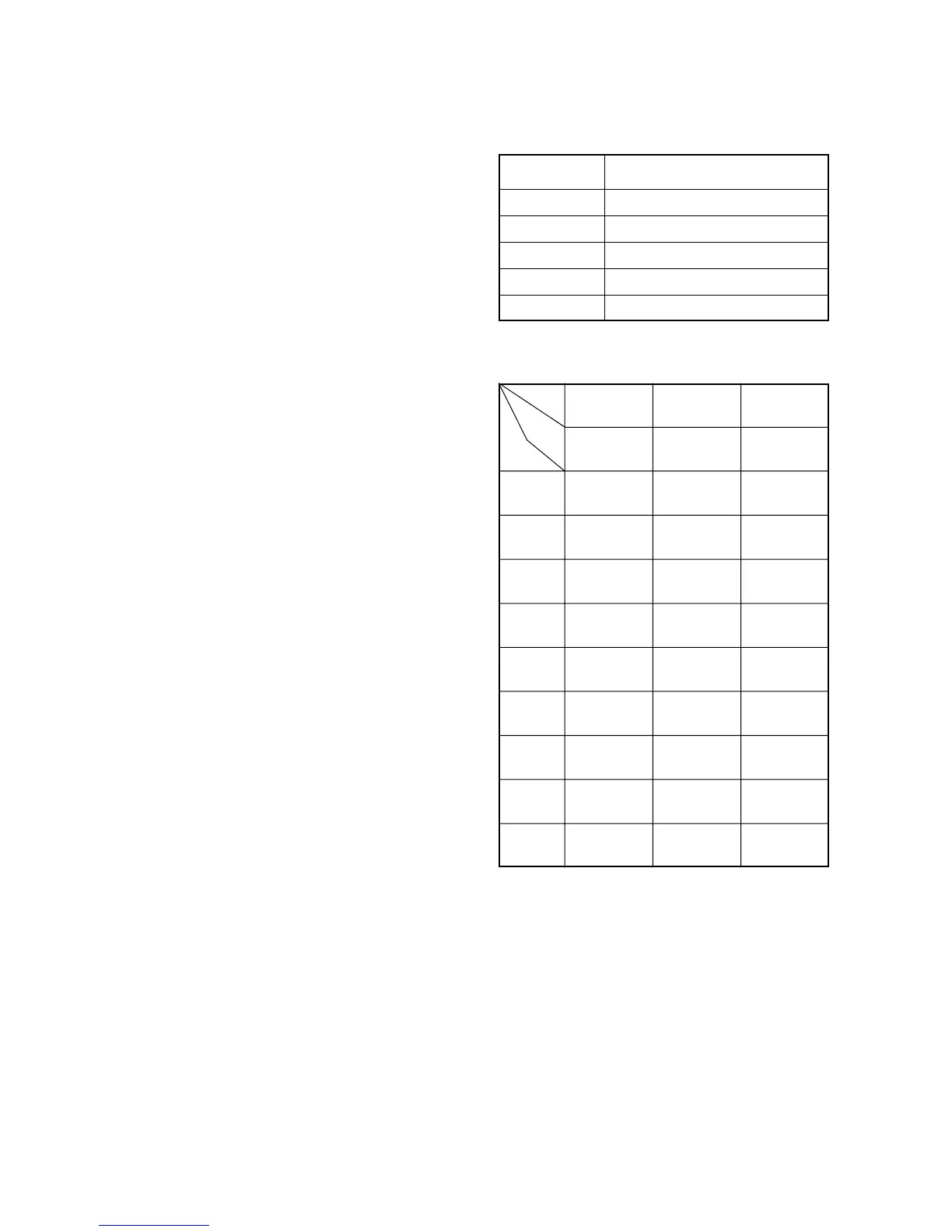

12.5 Bolt tightening table for each section

(1) Standard tightening torques for flare nuts.

Tightening torque N·m(kgf·cm)

9.8 ~ 19.6 (100 ~ 200)

19.6 ~ 29.4 (200 ~ 300)

29.4 ~ 39.2 (300 ~ 400)

39.2 ~ 49.0 (400 ~ 500)

49.0 ~ 58.8 (500 ~ 600)

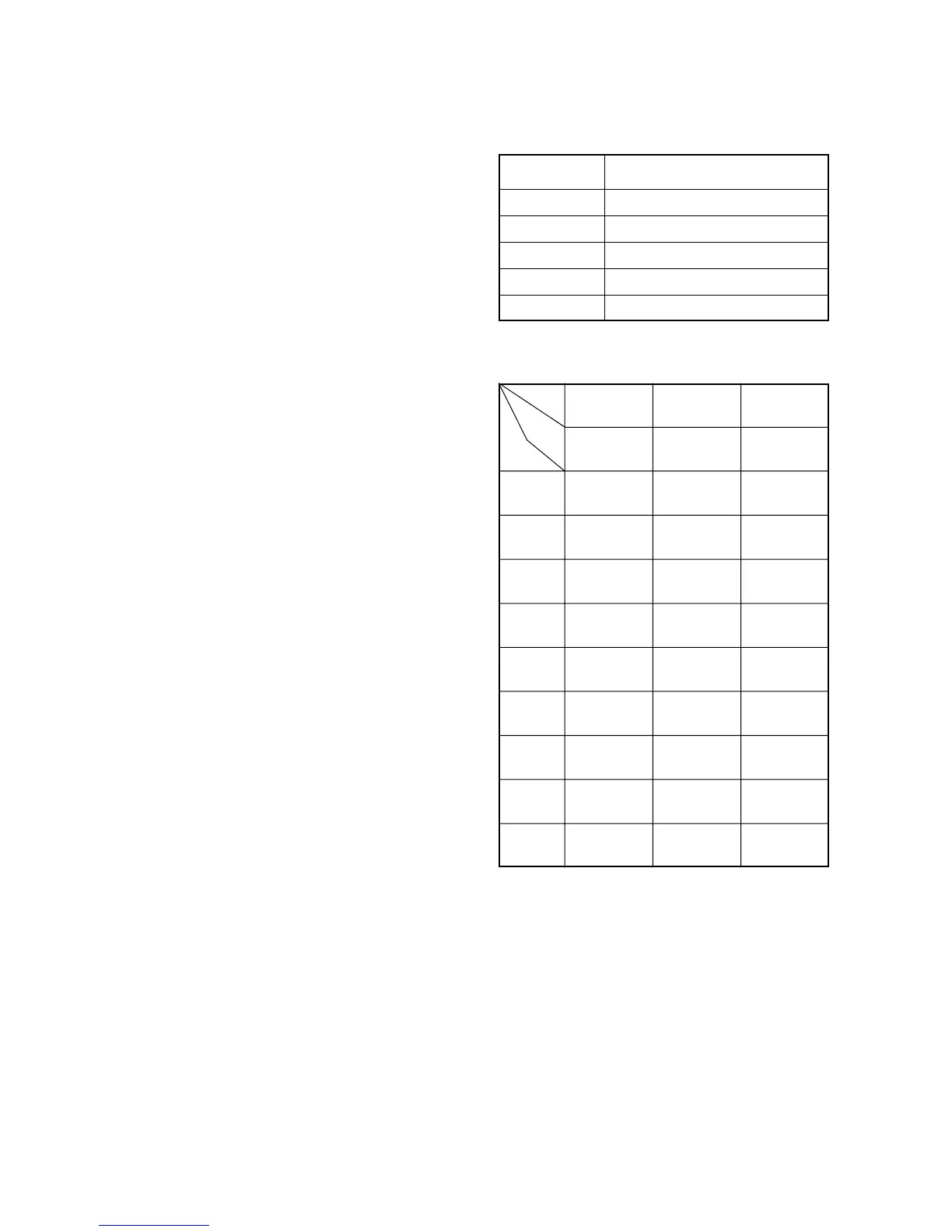

(2) Tightening torques of general N·m (kgf·cm)

SS41C S45C SUS304

No mark or 4 or 7 No mark

0.6 ~ 1.0 1.0 ~ 1.5 0.8 ~ 1.0

M3

(6 ~ 10) (10 ~ 15) (8 ~ 10)

1.0 ~ 1.5 2.0 ~ 3.0 2.0 ~ 2.5

M4

(10 ~ 15) (20 ~ 30) (20 ~ 25)

2.0 ~ 2.5 4.0 ~ 5.0 3.4 ~ 4.4

M5

(20 ~ 25) (40 ~ 50) (35 ~ 45)

3.5 ~ 4.4 6.9 ~ 8.3 6.4 ~ 7.8

M6

(36 ~ 45) (70 ~ 85) (65 ~ 80)

8.4 ~ 9.8 17.7 ~ 19.6 16.7 ~ 19.6

M8

(86 ~ 100) (180 ~ 200) (170 ~ 200)

17.0 ~ 19.6 35.3 ~ 40.2 33.3 ~ 38.2

M10

(173 ~ 200) (360 ~ 410) (340 ~ 390)

29.4 ~ 33.3 59.8 ~ 69.6 56.9 ~ 65.7

M12

(300 ~ 340) (610 ~ 710) (580 ~ 670)

47.1 ~ 53.0 96.1 ~ 107.9 91.2 ~ 104.9

M14

(480 ~ 540) (980 ~ 1100) (930 ~ 1070)

73.5 ~ 84.3 156.9 ~ 176.5 142.2 ~ 165.7

M16

(750 ~ 860) (1600 ~ 1800) (1450 ~ 1690)

– 35 –

Applicable

copper pipe

ø 6.35

ø 9.52

ø 12.7

ø 15.88

ø 19.05

Material

Head

mark

Thread

diameter

v

Loading...

Loading...