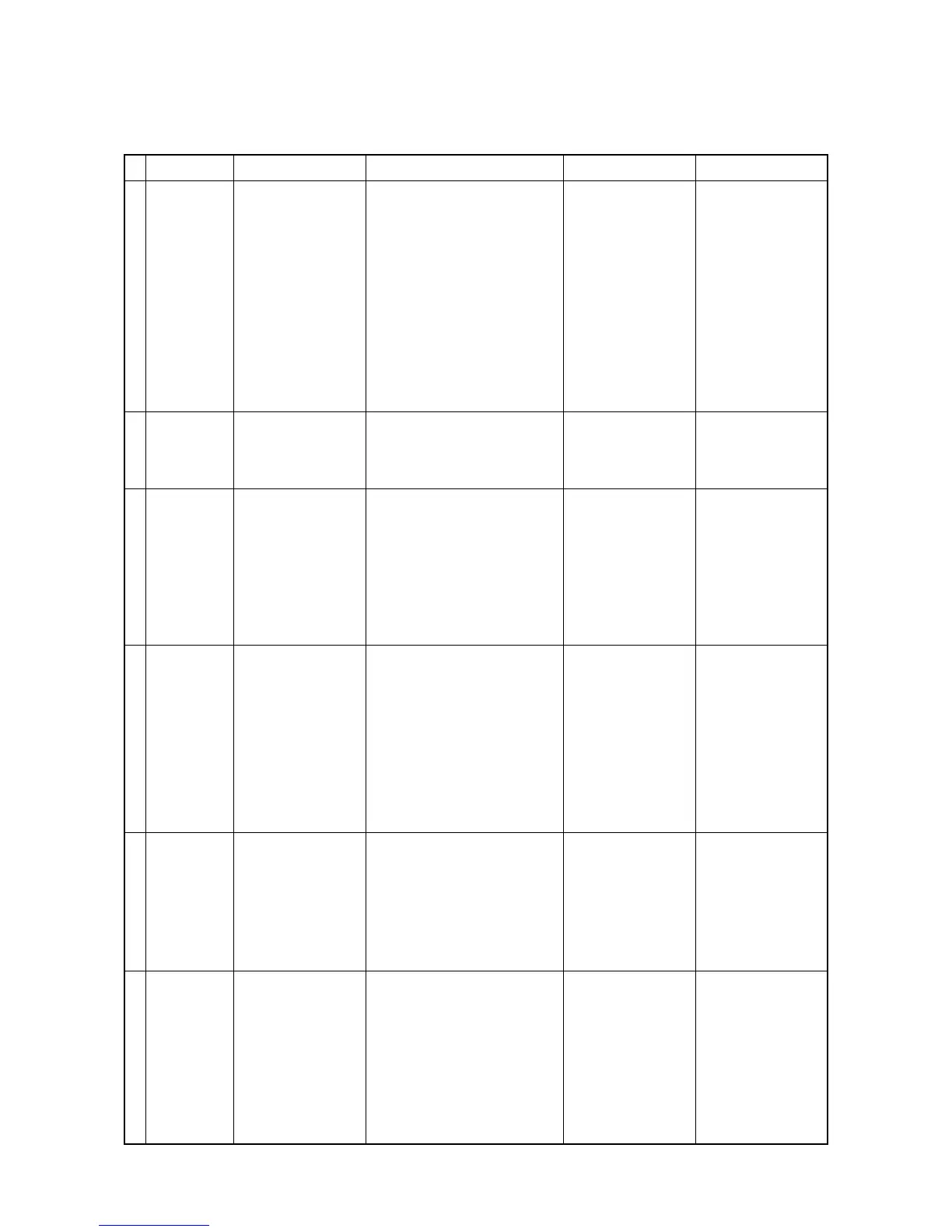

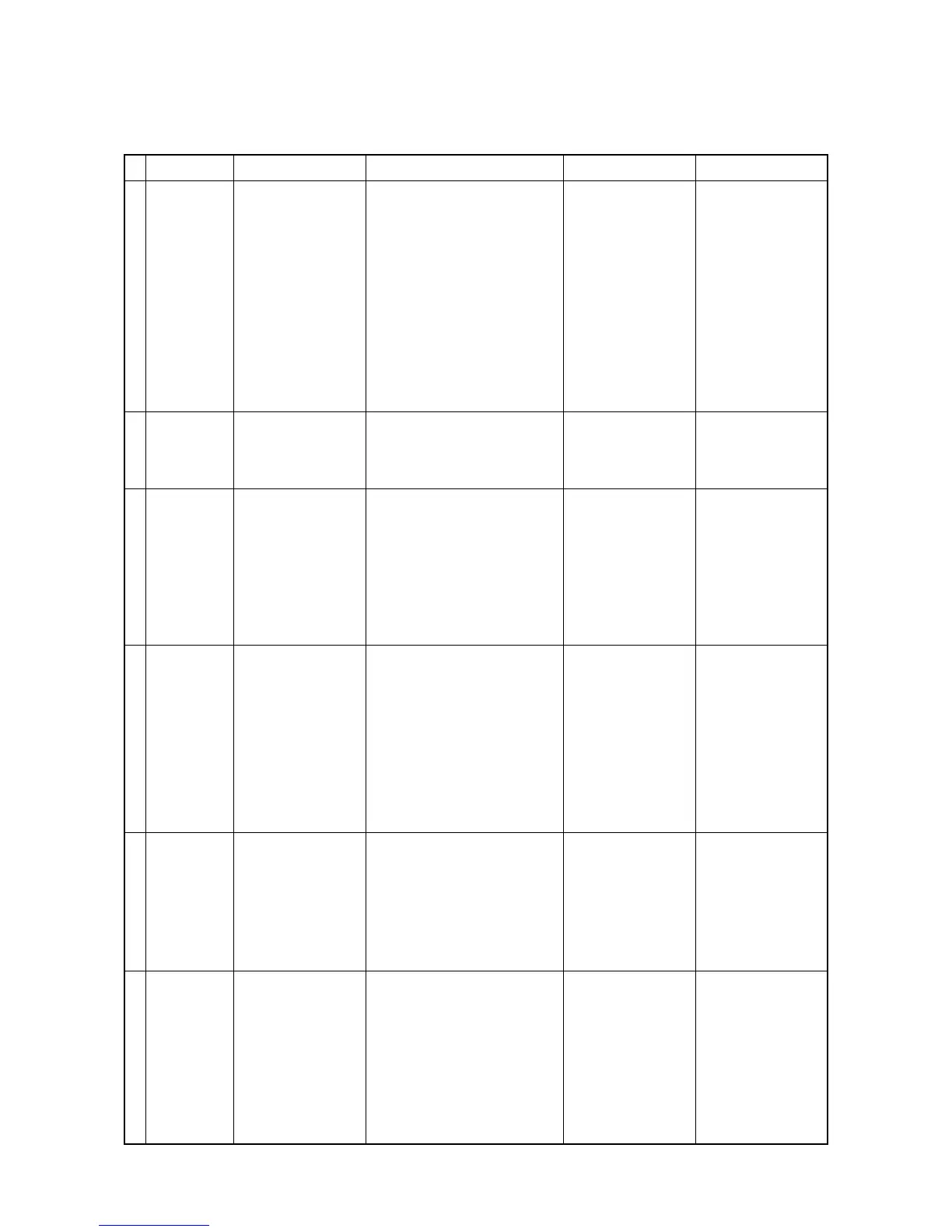

12.6 Caution to be taken at the time daily inspection

Instruct users to comply with the following items.

– 36 –

No. Item Contents Care to be taken at the time of operation Anticipated defect Disposition (remarks)

1

2

3

4

5

6

Check for gas

leakage

Washing of

condenser coil

Painting of the

body

Caution to be

taken when not

using for long

Caution to be

taken when the

refrigeration

unit is not

used.

Caution to be

taken when a

refrigerator

truck is used

instead of a

refrigerator.

• Perform this as a daily

inspection as the amount

of refrigerant and water

in the refrigeration can

be checked by sight

glass.

• Prevention of dropping of

heat exchange due to

stain of coil

• Disposition for peeling of

paint on the metal section

of the units which have

been used for long and

for occurrence of rust.

• When not using for long,

decrease the refrigerant

staying in the compressor

and prevent the shaft seal

from running out of oil.

• Do not remove the

compressor belt.

• Preparatory refrigeration,

keeping load in

refrigeration, in case of

using an power-driven

equipment sold at a

market for long instead

of a refrigeration in order

to refrigerate and excess

load at night, prevention

of defroster from troubles

1. Amount of refrigerant

When the amount of refrigerant is short

due to gas leakage, there are lots of

bubbles, and when extremely short, it

looks white (flashing condition)

2. Existence of water

It is normal when the check color is

green, and abnormal when the color is

yellow with more than 140ppm

(refrigerant temperature 38°C) water.

1. The fin will be crushed if it is washed

directly by high pressure water current.

So wash it with brush by water current

from a hose.

1. The rust generated on the painted

surface due to a frying stone or scratch,

will develop without being aware of it.

Rust in early stage can be well prevented

from developing by touch up.

1. When the unit is not used for long,

operate it about 15 minutes once in

every three or four days.

In case of type 2

(Run the engine and motor about 15

minutes once in every three or four days.

1. Do not remove the compressor belt even

if a vehicle is used and the refrigeration

is not used for long.

• In case of using a refrigerator truck for

long instead of a refrigerator, make a

storeroom temperature up to plus degree

once a week and melt the ice frosted.

1. Insufficient amount of

refrigerant

• Defective refrigeration

or no refrigeration

• Rizing of delivery gas

temperature

2. Inflow of water

• Clogging of expansion

valve

• Clogging of receiver

dryer or dryer

1. Stain of condenser coil.

Insufficient operation of

DPS and capacity of

refrigeration

1. Hole and crank in panel.

2. Falling off of panel

1. When the compressor is

not used for long, it will

hold refrigerant liquid in

it, which, when started,

will cause lack of

lubrication and burning

of the compressor. And

also running out of oil in

shaft seal section may

cause leakage of

refrigerant gas.

1. Though shaft bearings

are in the condition of

being fixed by tension of

belt, fretting corrosion

may be generated on

affected place due to

vibration if a vehicle is

run with belt removed.

1. Clogging of drain pipe

due to freezing of

defrosted water or

developing of ice due to

failure of draining may

crush defrost pipe and

cooling coil.

1. Check for leakage and

repair if any, and then

supply refrigerant.

2-1. After recovering

refrigerant and

replacing dryer,

vacuumize it and then

charge a fixed amount

of refrigerant.

2-2. Check and supply

amount of the

compressor in the

same way.

1. Remove and wash stain

of coil as often as

possible.

1. When occurrence of rust

is confirmed, clean the

affected place by sand

paper in early stage and

repair by touch up.

2. Replace the part which

has developed to opening

of hole or crack.

To a servicing shop.

Loading...

Loading...