12.7 Caution to be taken at the time of periodic inspection

– 38 –

No. Item Contents Care to be taken at the time of operation Anticipated defect Disposition (remarks)

1

2

3

4

Tension of belt

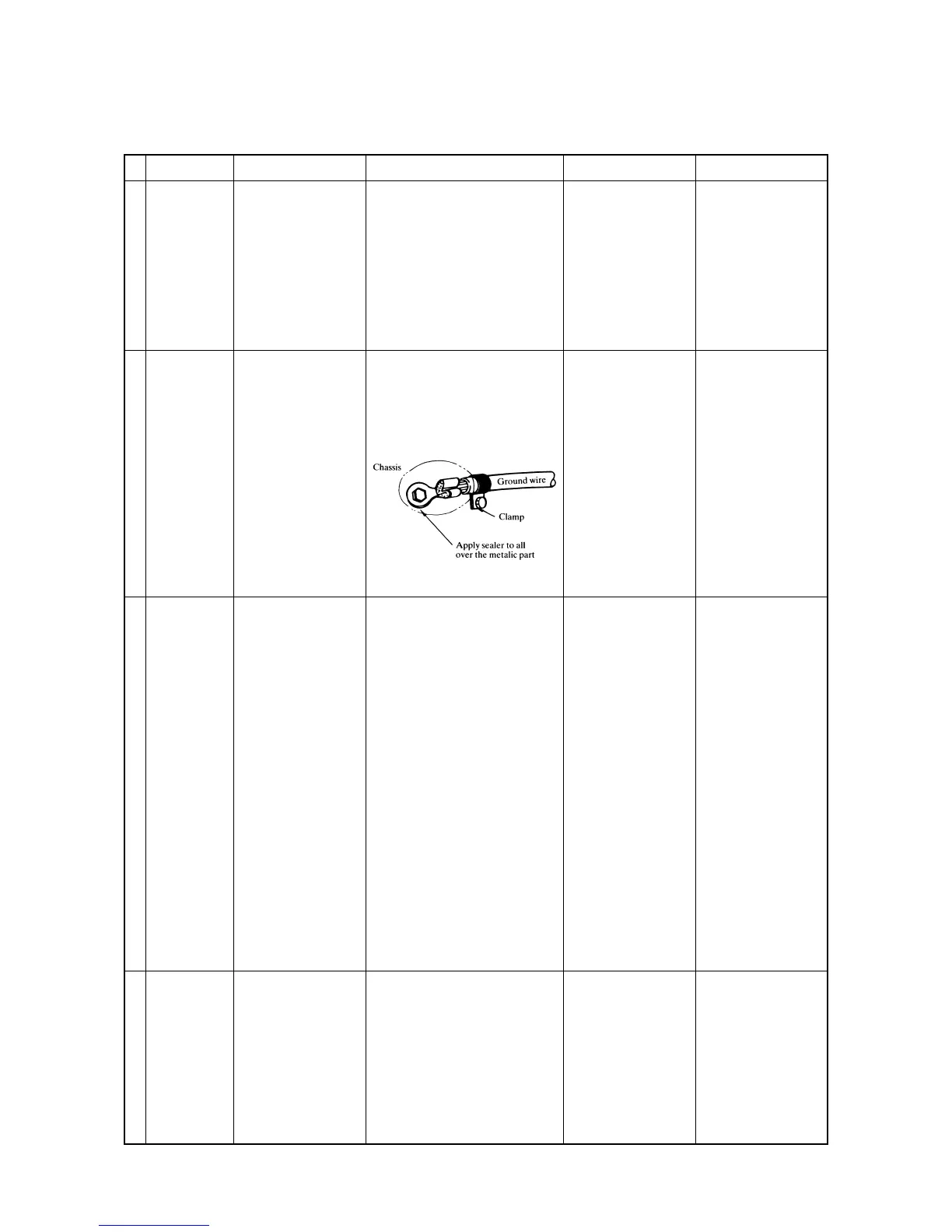

Inspection of a

ground wire on

the side of a

vehicle and

maintenance

and

disposition of

harness.

Washing

inside of

refrigerant

circuit and

operation for

cleaning

Refrigerating

machine oil

• Tension of belt between

direct coupled type

engine pulley, idle pulley

and clutch pulley

• Disposition of a ground

wire terminal for the unit

and vehicle chassis

• When compressor is

replaced due to

compressor accident,

check for refrigerant and

oil stain,

and *if necessary, wash

inside of the circuit or

operate for cleaning.

(*) In case of item 4 of

"anticipated defect"

shown on the right

hand column.

• Precaution when using

refrigerating machine oil

for charging to the

compressor.

1. Use tension meter to adjust belt and

provide with an appropriate tension.

2. As a new belt becomes stretched in its

early stage, re-fasten the belt after

operating about 10Hr.

3. After that, check and adjust every

100Hr.

1. Clamp the ground wire terminal and

apply sealer so as not to have its inside

broken during running of a car. Remove

painting on the side of a vehicle.

1. Washing inside of refrigerant

circuit

(1) Enclose HCFC141b and circulate by

another pump.

And after washing inside circuit,

recover HCFC141b and enclose

refrigerant after vacuumizing it.

2. Operation for cleaning

(1) Replace with a new compressor and

after vacuumizing it, charge gas and

perform cooling operation for about

an hour. (For type L specification,

perform defrost operation for about

15 minutes)

(2) After that, recover refrigerant and

replace receiver dryer or dryer.

Replace oil for compressor and once

again vacuumize and charge gas.

The above procedures will prevent a

compressor from becoming

defective again.

1. The refrigerating machine oil (Diamond

Freeze MA32) has an extremely high

absorbency, so work quickly when

handling it.

2. Never use leftover oil. Always dispose

of it.

3. Dispose of any refrigerating machine oil

in the oil can be used, and store it in a

dry state.

1. Too loose

• Slipping of belt

• Dropping of capacity

2. Too tight

• Abnormal pulley

bearing

• Premature wearing of

belt

• Breaking of engine

crank

1. Many defects which will

cause burning of relay,

etc.

2. Breaking of terminal due

to its corrosion

3. Failure of contact

1. No refrigeration

2. Clogging of expansion

valve

3. Clogging of dryer

4. Symptom of compressor

• In case of burning

• In case of remaining oil

having nearly black

color and metal powder

mixed.

• In case of having much

wear and many

scratches on the sliding

surface of cylinder,

piston and rod.

When such symptoms as

above have occurred,

same kind of defect may

happen again soon as it is

possible that the

refrigerant circuit is

stained even after

replacing the compressor.

1. Clogging may occur in

each section if

refrigerating machine oil

exposed to air for a long

time is used.

1. Proper tension

• Direct coupled type

Bending of 7 ~ 10mm

when pushed by 98N

(10kg) force

1. Confirm at each

inspection.

2. Apply sealer to each

terminal of wiring

(except inside of control

box)

1. HCFC141b is a

refrigerant for washing.

1. Do not use refrigerating

machine oil that has been

exposed to air for a long

time.

Loading...

Loading...