– 70 –

No. Item Explanation Precaution for service Possible failure Corrective action (Remarks)

11

12

Installation

direction of

compressor

Tightening

torques of flare

nuts, general

bolts and nuts

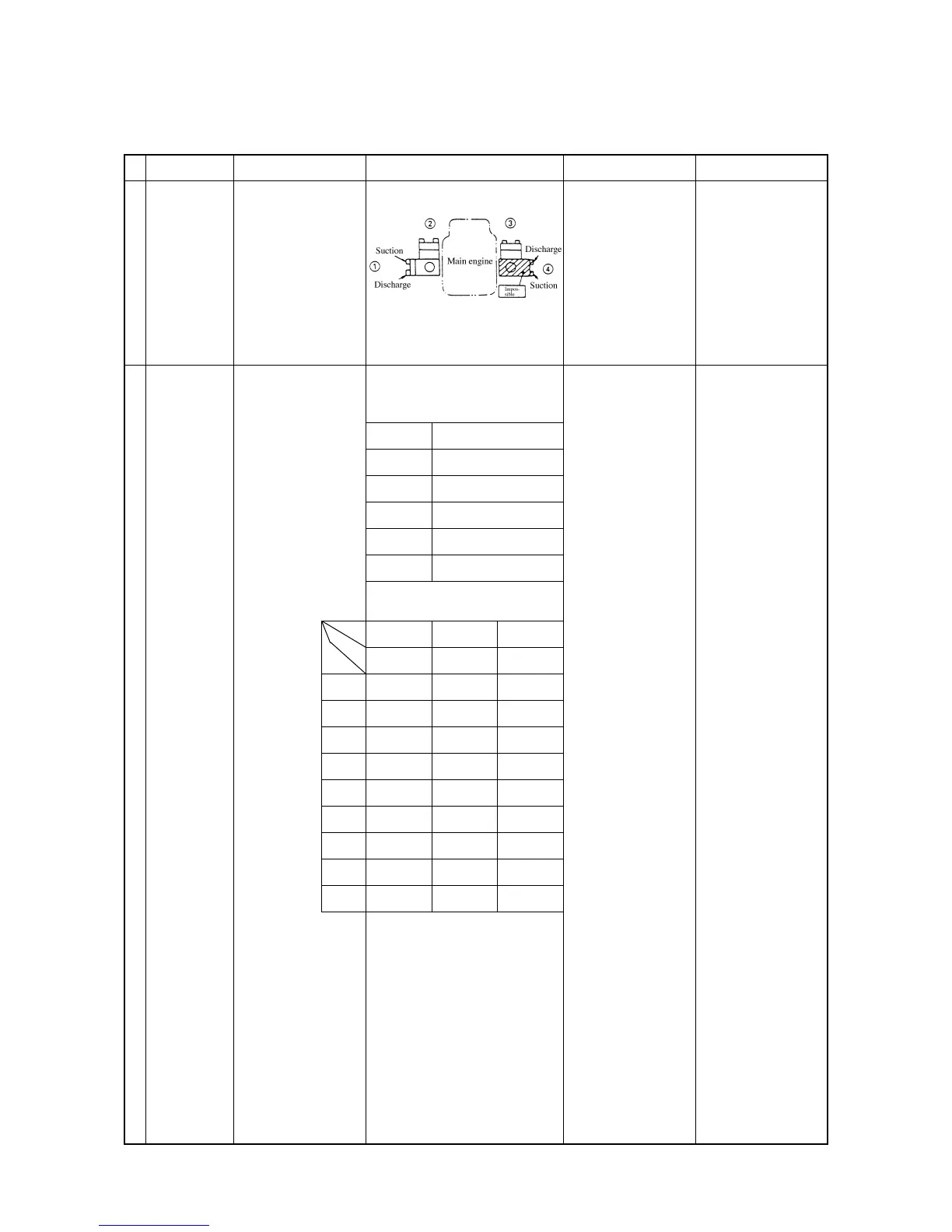

• The installation direction

of the compressor is

restricted.

• Rain water is prevented

from entering the van,

and the refrigerating

capacity is prevented

from dropping.

In case of CR2211L-A

The installation directions 1, 2 and 3

above are possible.

The direction 4 is impossible.

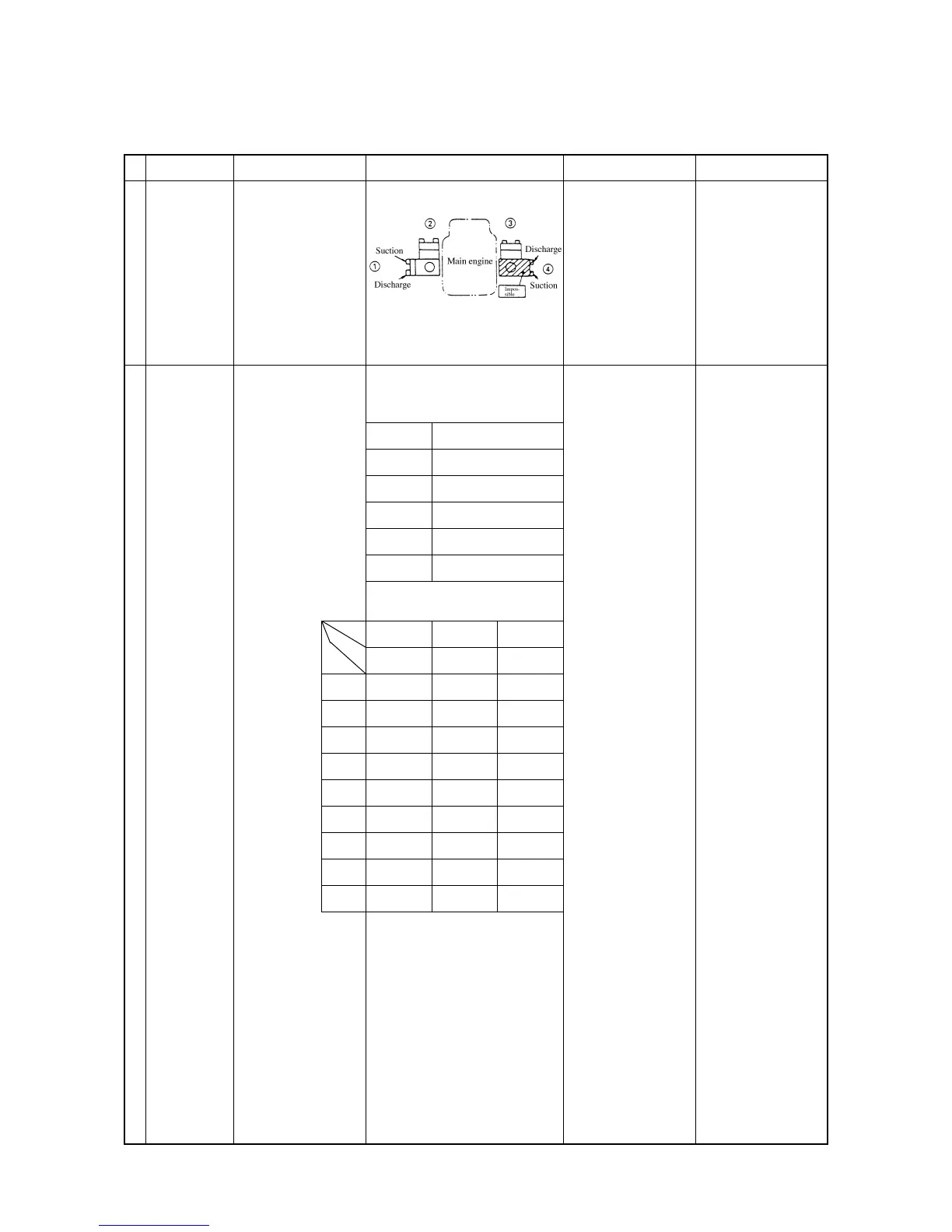

(observe the following tightening torques)

1. Standard tightening torques for flare

nuts

2. Tightening torques of general bolts

N·m (kgf·cm)

1. Compressor may be

damaged since liquid is

compressed at the start

because of liquid

accumulation.

1. Gas leaks on the

refrigerant piping system

2. General bolts and nuts

• If overightened, the

bolt may break owing

to the excessive

elongation.

• If insufficiently

tightened, looseness

may lead to troubles.

1. If the direction 4 in the

left is inevitably applied,

separately order the

compression on which

the discharge and suction

are reversed since it is

available for

replacement.

1. Periodically retighten the

bolt and nut, and check

that they are tightened to

the specified torques.

(Take sufficient care for

over tightening.)

Applicable

copper pipe

ø6.35

ø9.52

ø12.7

ø15.88

ø19.05

Tightening torque

N·m (kgf·cm)

9.8 ~ 19.6 (100 ~ 200)

19.6 ~ 29.4 (200 ~ 300)

29.4 ~ 39.2 (300 ~ 400)

39.2 ~ 49.0 (400 ~ 500)

49.0 ~ 58.8 (500 ~ 600)

Material

Head mark

Thread

diameter

M3

M4

M5

M6

M8

M10

M12

M14

M16

SS41C

No mark or 4

0.6 ~ 1.0

(6 ~ 10)

1.0 ~ 1.5

(10 ~ 15)

2.0 ~ 3.0

(20 ~ 30)

3.4 ~ 4.4

(35 ~ 45)

8.4 ~ 9.8

(86 ~ 100)

17.0 ~ 19.6

(173 ~ 200)

29.4 ~ 33.3

(300 ~ 340)

47.1 ~ 53.0

(480 ~ 540)

73.5 ~ 84.3

(750 ~ 860)

S45C

or 7

1.0 ~ 1.5

(10 ~ 15)

2.0 ~ 3.0

(20 ~ 30)

4.0 ~ 5.0

(40 ~ 50)

6.9 ~ 8.3

(70 ~ 85)

17.7 ~ 19.6

(180 ~ 200)

35.3 ~ 40.2

(360 ~ 410)

59.8 ~ 69.6

(610 ~ 710)

96.1 ~ 107.9

(980 ~ 1100)

156.9 ~ 176.5

(1600 ~ 1800)

SUS304

No mark

0.8 ~ 1.0

(8 ~ 10)

2.0 ~ 2.5

(20 ~ 25)

3.4 ~ 4.4

(35 ~ 45)

6.4 ~ 7.8

(65 ~ 80)

16.7 ~ 19.6

(170 ~ 200)

33.3 ~ 38.2

(340 ~ 390)

56.9 ~ 65.7

(580 ~ 670)

91.2 ~ 104.9

(930 ~ 1070)

142.2 ~ 165.7

(1450 ~ 1690)

v

Loading...

Loading...