MBM-Series Owner’s Manual

7

Copyright© 2015 Mod-U-Blast®, All Rights Reserved

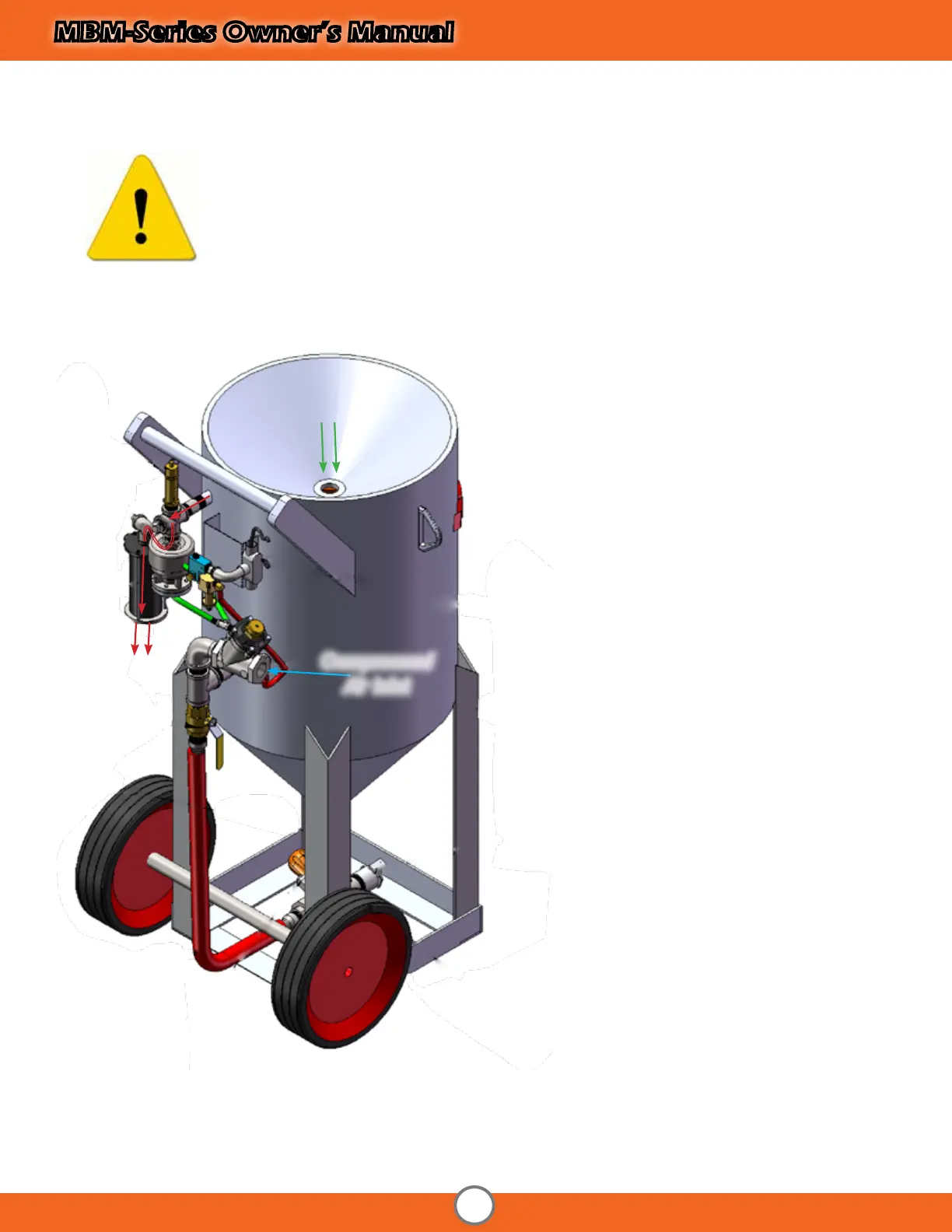

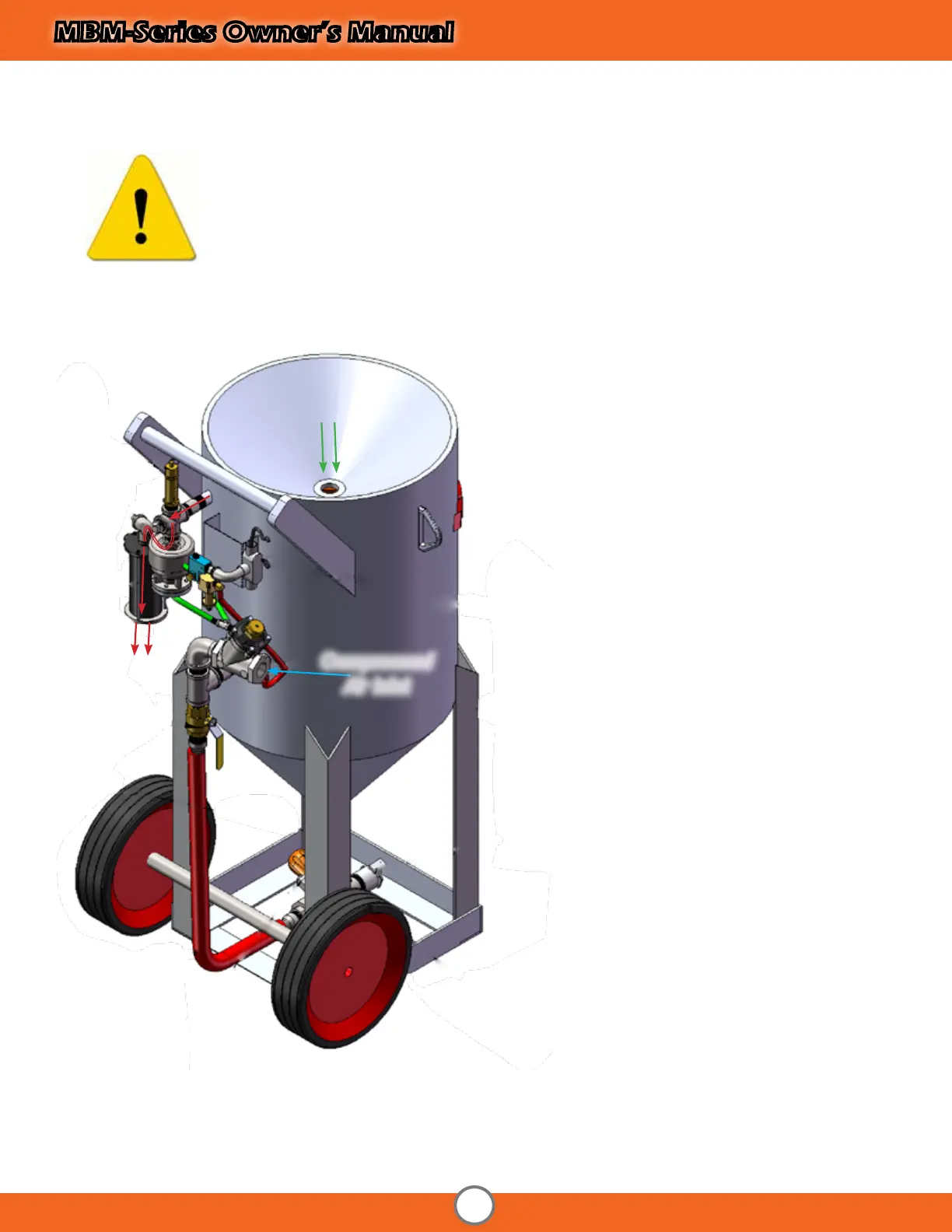

How MBM-Series Systems Work Pressure release with Auto Air Valve / micro valve

Warning: This section of the manual is designed to give you a general understanding of how the

Abrasive Blaster functions. ALL sections of this manual must be read and understood before operat-

ing the equipment.

ADDING ABRASIVE

PRESSURIZATION

DEPRESSURIZATION (Blow - Down)

When the control handle is released in a pressure release

system, the reverse effect takes place in the blast system.

The Auto Air Valve closes stopping the air ow and the

dump valve opens causing a quick release of compressed

air.

Abrasive is added through the hole in the top of the

blaster where the pop-up and seal are located. It ows

down through the hole, around the pop-up, and down

the bottom of the pressure vessel where it exits through the

metering valve.

When a compressed air source (such as an air-compres-

sor) is connected to the inlet of the Abrasive blaster and

the inlet valve is opened, compressed air ows through the

moisture separator (if equipped) and reaches the Auto

Air Valve where it is stopped. When the control handle is

activated, the Auto Air Valve opens while the dump valve

closes and the air ows through into the pressure vessel

causing the Pop-Up (located internally) to seal against its

seat. The pressure vessel is now sealed and pressurized. Air

will continue past the choke valve to the metering valve

where it is mixed with abrasive . The mixture of compressed

air will now exit the Abrasive Blaster through a blast hose

and nozzle connected to the coupling on the metering

valve and blasting begins.

Loaded Abrasive

Compressed

Air Inlet

Exhausted

Air

Loading...

Loading...