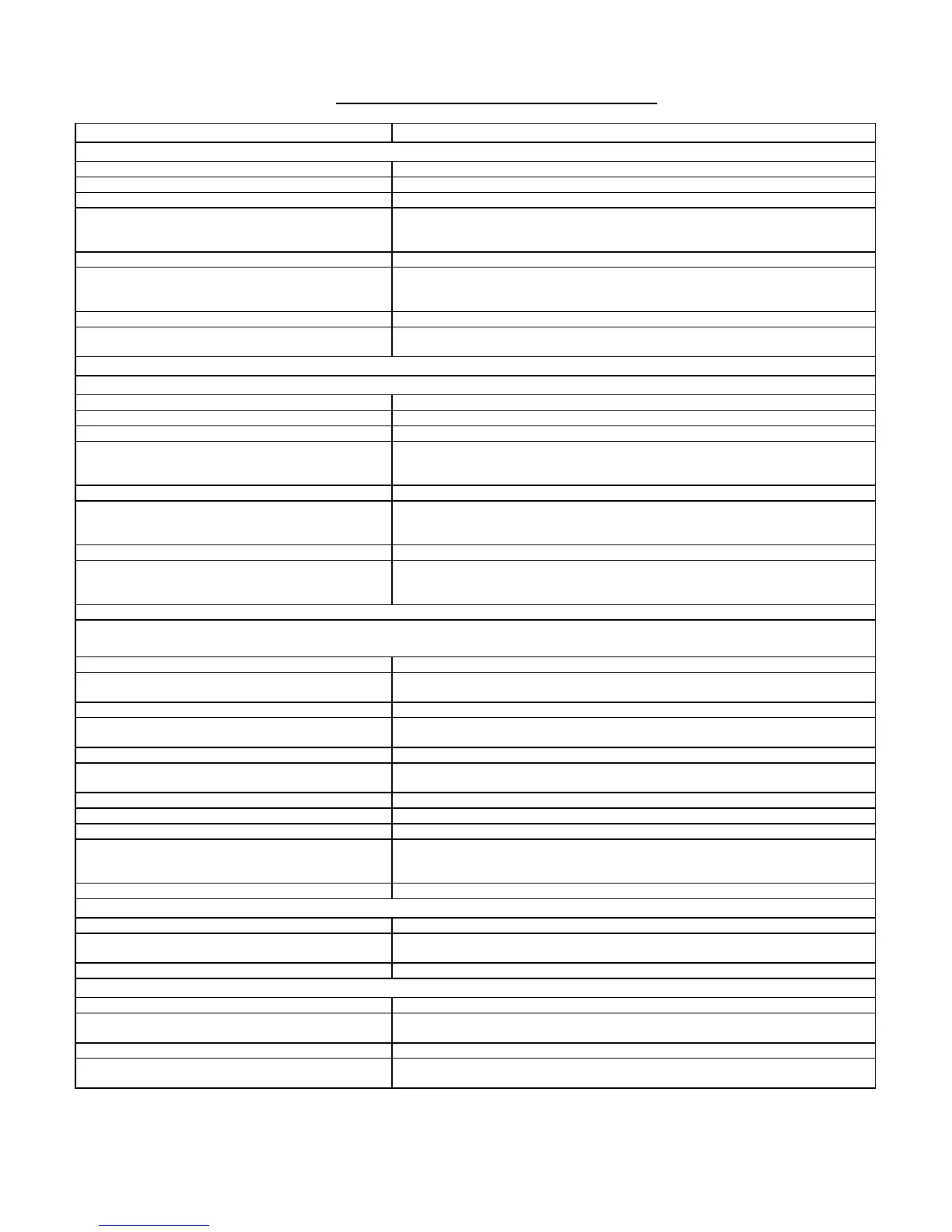

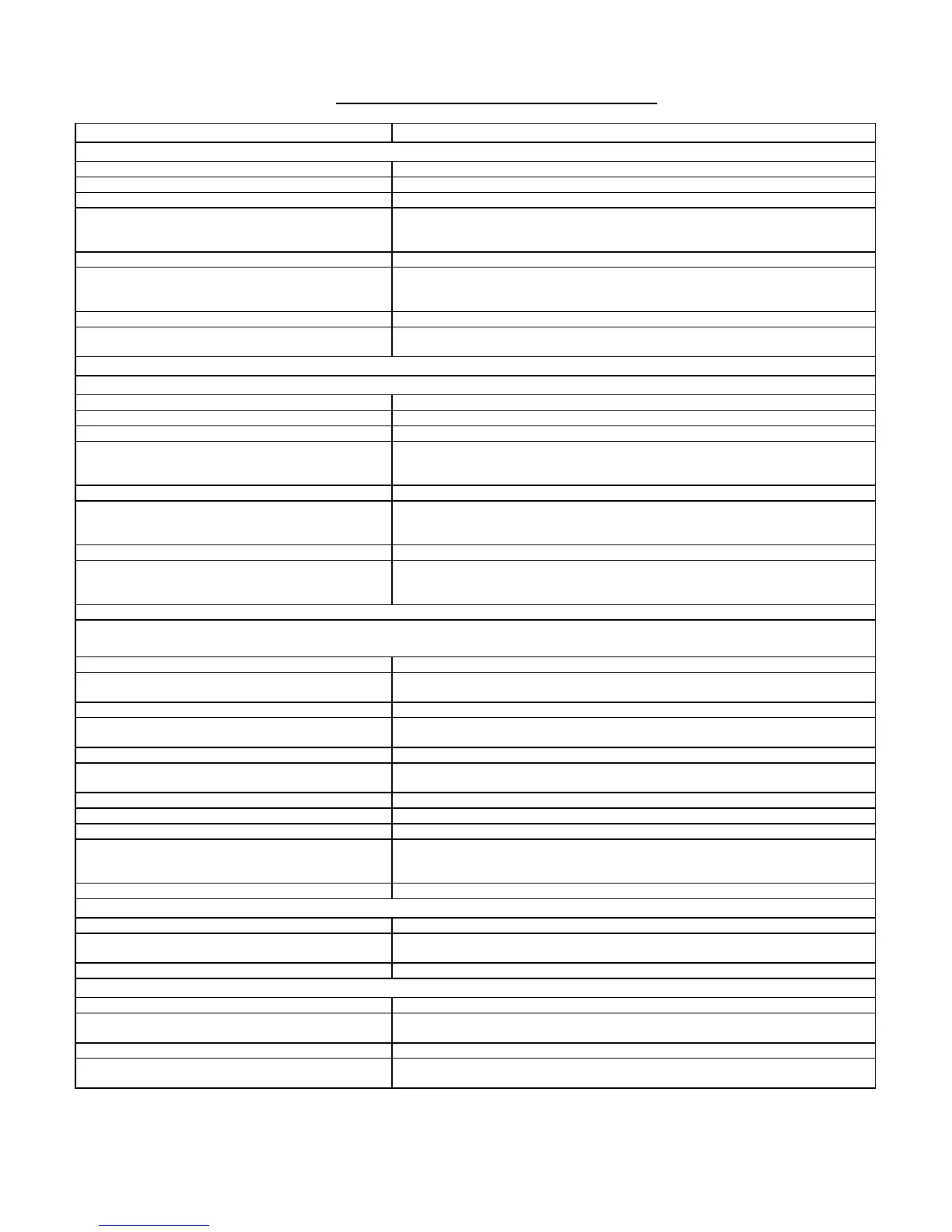

MOHAWK MODELS SYSTEM IA & SYSTEM IA-10

TROUBLE SHOOTING, CONTINUED

RAISING UNEVEN, CONTINUED

USE SPECIAL LIFT PADS. SEE FIGURE 13.

REMOVE BLEED LINE FROM THE TOP OF THE OFF SIDE CYLINDER AND CAP

USING MOHAWK PART # 601-420-001. IF THE UNIT CONTINUES TO DRIFT DOWN

THE DIVERTER PULL VALVE WILL NEED TO BE CLEANED OR REPLACED.

REMOVE BLEED LINE FROM THE TOP OF THE OFF SIDE CYLINDER AND CAP

USING MOHAWK PART # 601-420-001. IF THE UNIT NO LONGER DRIFTS DOWN

THE BLEEDER VALVE WILL NEED TO BE SERVICED OR REPLACED..

PERFORM HYDRAULIC SAFETY CHECKS. CHECK FOR INTERNAL HYDRAULIC

LEAKS

RAISE UNIT TO RE-ENGAGE SAFETIES. THEN LOWER UNIT ONTO SAFETIES.

POWER UNIT LOWERING VALVE

CONTAMINATION

BACK FLUSH POWER UNIT: PULL DOWN ON THE LOWERING HANDLE, AND

THEN ENGAGE THE UP BUTTON AT THE SAME TIME. RUN UNIT APPROX. 10

SECONDS

REMOVE BLEED LINE FROM THE TOP OF THE OFF SIDE CYLINDER AND CAP

USING MOHAWK PART # 601-420-001. IF THE UNIT CONTINUES TO DRIFT DOWN

THE DIVERTER PULL VALVE WILL NEED TO BE CLEANED OR REPLACED.

REMOVE BLEED LINE FROM THE TOP OF THE OFF SIDE CYLINDER AND CAP

USING MOHAWK PART # 601-420-001. IF THE UNIT NO LONGER DRIFTS DOWN

THE BLEEDER VALVE WILL NEED TO BE SERVICED OR REPLACED..

EXTERNAL HYDRAULIC LEAKS

NOTE: TIGHTEN ALL FITTINGS PER SPECIFICATIONS

THOROUGHLY CLEAN THE CYLINDER. VERIFY LEAK ORIGIN. FITTINGS ARE

TO BE TIGHTENED PER SPECIFICATIONS

THOROUGHLY CLEAN THE CYLINDER. VERIFY LEAK ORIGIN. FITTINGS ARE

TO BE TIGHTENED PER SPECIFICATIONS.

REMOVE THE HYDRAULIC LINE AND INSPECT FLAIR AND FITTING FOR

DEFORMATION. REPLACE IF NEEDED.

BAD O-RING (O-RING TYPE FITTINGS)

REMOVE, RESEAL, AND RE-INSTALL FITTING.

SEAL ALL PIPE FITTING CONNECTIONS WITH THREAD SEALANT MOHAWK

PART # 601-610-002 NOTE: DO NOT USE TEFLON TAPE.

MECHANICAL LOCK RE-ENGAGES

CHAIN BREAK SAFETY CABLE NEEDS

ADJUSTMENT

TENSION IN CABLE MAY BE TO TIGHT. REFER TO FIGURE 15.

MECHANICAL LOCK HARD TO PULL

CHAIN BREAK SAFETY CABLE NEEDS

ADJUSTMENT

TENSION IN CABLE MAY BE TO TIGHT. REFER TO FIGURE 15.

FLIPPER STICKING ONTO LOCK BAR

APPLY A SMALL AMOUNT OF LUBRICANT TO THE LOCK BAR WHERE THE

FLIPPER RIDES. (DO NOT USE HEAVY GREASE)

Loading...

Loading...