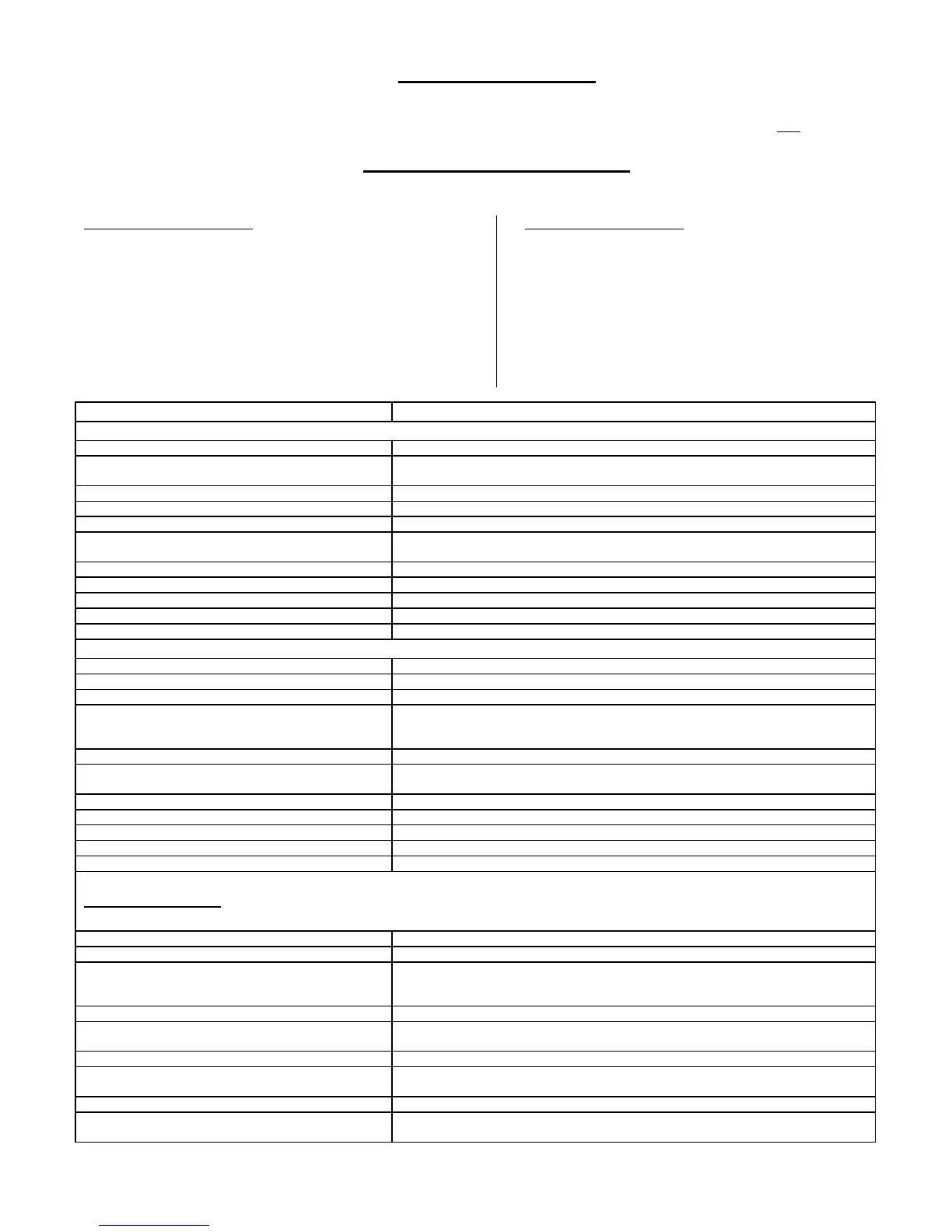

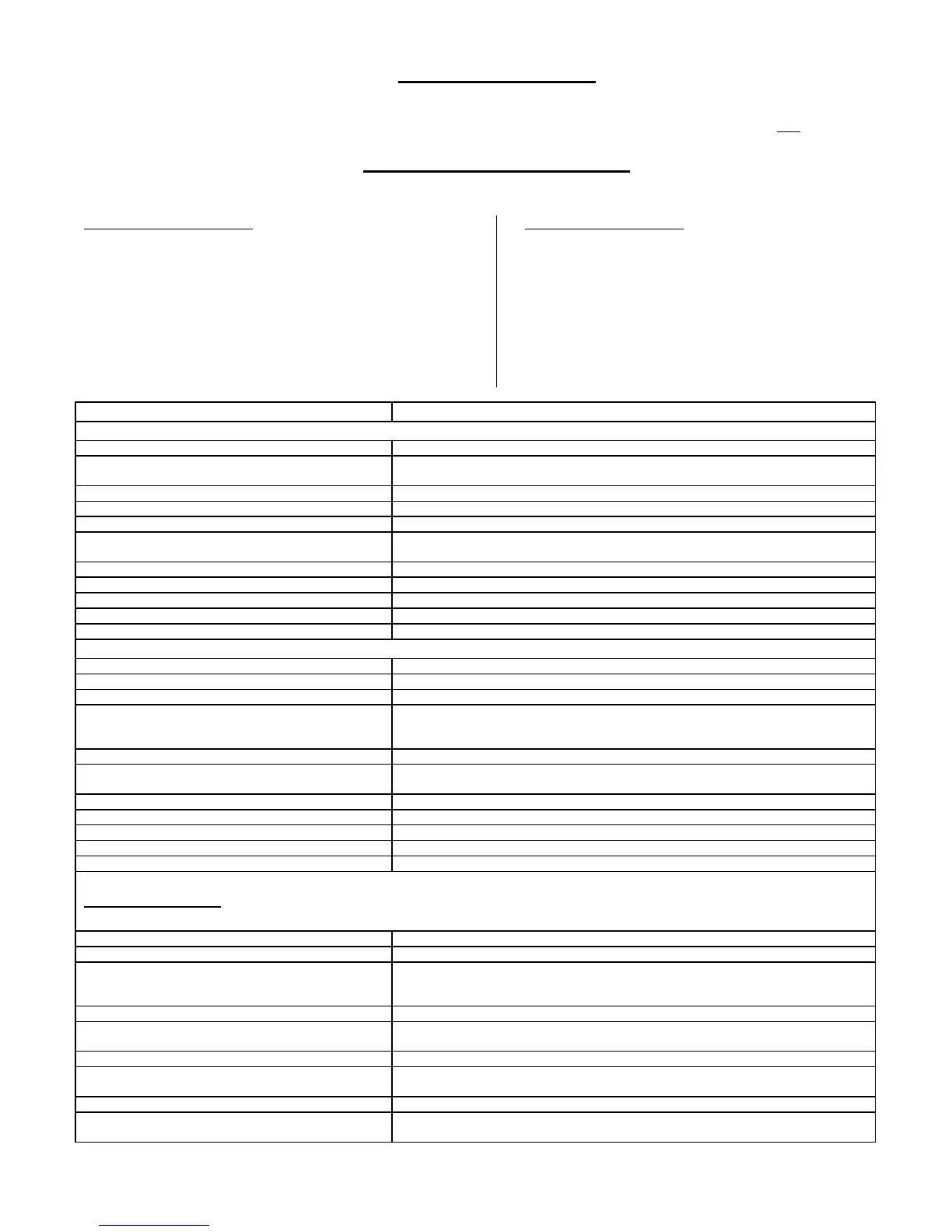

MOHAWK MODELS SYSTEM IA & SYSTEM IA-10

TROUBLE SHOOTING

WARNING: NEVER ATTEMPT TO LOOSEN HYDRAULIC FITTINGS, OR OVERRIDE SAFETY DEVICES IN AN

ATTEMPT TO CORRECT A PROBLEM. ALL TESTS ARE TO BE PERFORMED WITH NO VEHICLE.

HYDRAULIC SAFETY CHECK

NOTE: THE HYDRAULIC SAFETY CHECK IS TO BE PERFORMED WITH NO VEHICLE ON THE UNIT.

CONTACT YOUR LOCAL MOHAWK DISTRIBUTOR OR THE MOHAWK FACTORY IF EITHER TEST FAILS.

MAINSIDE SAFETY CHECK:

1. RAISE THE UNIT APPROXIMATELY 3 FEET

2. DISENGAGE THE OFFSIDE MECHANICAL SAFETY

3. LOWER THE UNIT ONTO THE MAINSIDE MECHANICAL

SAFETY

4. WHILE CONTINUING TO HOLD DOWN THE POWER UNIT

LOWERING HANDLE, OBSERVE THE OFFSIDE

CARRIAGE FOR MOVEMENT. THE UNIT HAS CHECK

OUT OK IF THERE IS NO MOVEMENT (OFFSIDE

CARRIAGE DOES NOT CONTINUE TO LOWER)

OFFSIDE SAFETY CHECK:

1. RAISE THE UNIT APPROXIMATELY 3 FEET

2. DISENGAGE THE MAINSIDE MECHANICAL SAFETY

3. LOWER THE UNIT ONTO THE OFFSIDE MECHANICAL

SAFETY

4. WHILE CONTINUING TO HOLD DOWN THE POWER UNIT

LOWERING HANDLE, OBSERVE THE MAINSIDE

CARRIAGE FOR MOVEMENT. THE UNIT HAS CHECK

OUT OK IF THERE IS NO MOVEMENT (MAINSIDE

CARRIAGE DOES NOT CONTINUE TO LOWER)

LOW HYDRAULIC FLUID LEVEL

LOWER UNIT. REMOVE RESERVOIR BREATHER CAP. FILL UNIT TO WITHIN 1/2

INCH BELOW PORT. USE DEXRON III TRANSMISSION / HYDRAULIC FLUID.

PRESSURE RELIEF ADJUSTMENT

CONSULT MOHAWK SERVICE DEPARTMENT

PRESSURE RELIEF CONTAMINATION

REFER TO POWER UNIT SPECIFICATIONS. REMOVE AND CLEAN DEBRIS FROM

VALVE ASSEMBLY.

REFER TO POWER UNIT SPECIFICATIONS. CONSULT AN ELECTRICIAN

VEHICLE IS TO HEAVY TO BE RAISED

RAISE UNIT. DISENGAGE MECHANICAL LOCKS.

UNIT UNEVEN (SIDE TO SIDE)

RAISE UNIT TO FULL HEIGHT TO EQUALIZE. THEN LOWER

OR

USE DIVERTER VALVE TO EQUALIZE

VERIFY LEVEL ASSEMBLY. MAKE ANY AND ALL NECESSARY ADJUSTMENTS.

SEE FIGURE 7 , 8&8A.

DEBRIS IN POSTS (TOOLS ETC.)

OBSTRUCTION UNDER VEHICLE OR LIFT

RAISING UNEVEN

RULE OF THUMB: IF THE MAIN SIDE IS HIGH, RUN UNIT TO FULL HEIGHT. IF THE MAIN SIDE IS LOW, LOWER UNIT TO

FLOOR. ALLOW TIME FOR THE OFF SIDE TO EQUALIZE.

BLEED UNIT. REFER TO BLEEDING PROCEDURES.

CARRIAGE BEARINGS CONTACTING CARRIAGE

STOPS

CARRIAGE BEARINGS ON THE MAIN SIDE MUST NOT CONTACT CARRIAGE

STOPS. (RESULT OF INCORRECT CYLINDER SHIMS.) SEE “SHIMMING FOR

CHAIN TENSION” SECTION. SEE FIGURE 10.

VERIFY LEVEL ASSEMBLY. MAKE ANY AND ALL NECESSARY ADJUSTMENTS.

SEE FIGURE 7 , 8&8A.

VERIFY CYLINDER SHIMS. MAKE ANY AND ALL NECESSARY ADJUSTMENTS.

SEE “SHIMMING FOR CHAIN TENSION” SECTION. SEE FIGURE 10.

VERIFY PROPER INSTALLATION OF MAIN SIDE POST. MAIN SIDE TO BE ON

HIGH SIDE. SEE FIGURE 12.

Loading...

Loading...